Are you a seasoned CNC Programmer (Computer Numerical Control Programmer) seeking a new career path? Discover our professionally built CNC Programmer (Computer Numerical Control Programmer) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

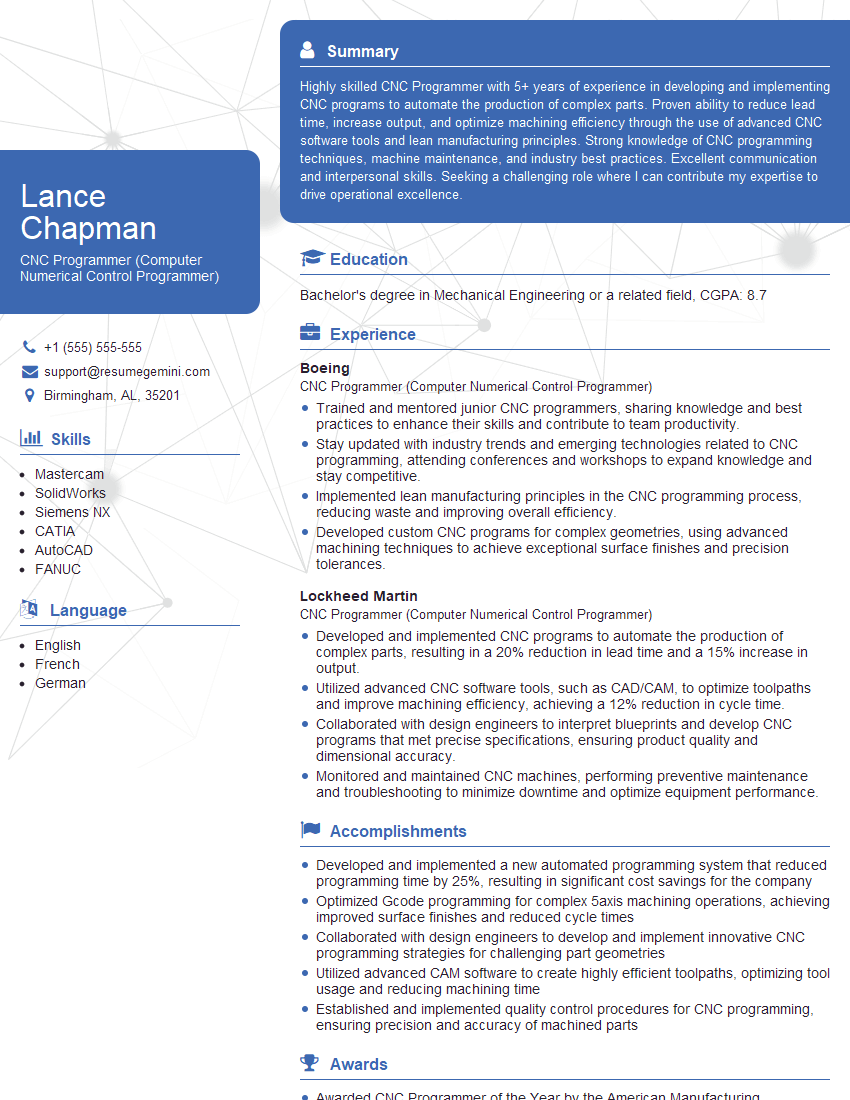

Lance Chapman

CNC Programmer (Computer Numerical Control Programmer)

Summary

Highly skilled CNC Programmer with 5+ years of experience in developing and implementing CNC programs to automate the production of complex parts. Proven ability to reduce lead time, increase output, and optimize machining efficiency through the use of advanced CNC software tools and lean manufacturing principles. Strong knowledge of CNC programming techniques, machine maintenance, and industry best practices. Excellent communication and interpersonal skills. Seeking a challenging role where I can contribute my expertise to drive operational excellence.

Education

Bachelor’s degree in Mechanical Engineering or a related field

February 2015

Skills

- Mastercam

- SolidWorks

- Siemens NX

- CATIA

- AutoCAD

- FANUC

Work Experience

CNC Programmer (Computer Numerical Control Programmer)

- Trained and mentored junior CNC programmers, sharing knowledge and best practices to enhance their skills and contribute to team productivity.

- Stay updated with industry trends and emerging technologies related to CNC programming, attending conferences and workshops to expand knowledge and stay competitive.

- Implemented lean manufacturing principles in the CNC programming process, reducing waste and improving overall efficiency.

- Developed custom CNC programs for complex geometries, using advanced machining techniques to achieve exceptional surface finishes and precision tolerances.

CNC Programmer (Computer Numerical Control Programmer)

- Developed and implemented CNC programs to automate the production of complex parts, resulting in a 20% reduction in lead time and a 15% increase in output.

- Utilized advanced CNC software tools, such as CAD/CAM, to optimize toolpaths and improve machining efficiency, achieving a 12% reduction in cycle time.

- Collaborated with design engineers to interpret blueprints and develop CNC programs that met precise specifications, ensuring product quality and dimensional accuracy.

- Monitored and maintained CNC machines, performing preventive maintenance and troubleshooting to minimize downtime and optimize equipment performance.

Accomplishments

- Developed and implemented a new automated programming system that reduced programming time by 25%, resulting in significant cost savings for the company

- Optimized Gcode programming for complex 5axis machining operations, achieving improved surface finishes and reduced cycle times

- Collaborated with design engineers to develop and implement innovative CNC programming strategies for challenging part geometries

- Utilized advanced CAM software to create highly efficient toolpaths, optimizing tool usage and reducing machining time

- Established and implemented quality control procedures for CNC programming, ensuring precision and accuracy of machined parts

Awards

- Awarded CNC Programmer of the Year by the American Manufacturing Association for outstanding contributions to the field

- Recognized with the Excellence in CNC Programming award by the International Association of Machinists and Aerospace Workers

- Won the Master CNC Programmer certification from the National Institute for Metalworking Skills

- Received the Top CNC Programmer award from the Society of Manufacturing Engineers for exceptional skills and contributions

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified CNC Programmer (CCNP)

- Mastercam Certified Professional (MCP)

- SolidWorks Certified Professional (CSWP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Programmer (Computer Numerical Control Programmer)

- Highlight your experience in developing and implementing CNC programs for complex parts, quantifying the results whenever possible.

- Demonstrate your proficiency in using advanced CNC software tools, such as CAD/CAM, to optimize toolpaths and improve machining efficiency.

- Emphasize your ability to collaborate with design engineers to interpret blueprints and develop CNC programs that meet precise specifications.

- Showcase your skills in monitoring and maintaining CNC machines, performing preventive maintenance and troubleshooting to minimize downtime and optimize equipment performance.

- Highlight your ability to train and mentor junior CNC programmers, sharing knowledge and best practices to enhance their skills and contribute to team productivity.

Essential Experience Highlights for a Strong CNC Programmer (Computer Numerical Control Programmer) Resume

- Develop and implement CNC programs to automate the production of complex parts

- Utilize advanced CNC software tools, such as CAD/CAM, to optimize toolpaths and improve machining efficiency

- Collaborate with design engineers to interpret blueprints and develop CNC programs that meet precise specifications

- Monitor and maintain CNC machines, performing preventive maintenance and troubleshooting to minimize downtime and optimize equipment performance

- Train and mentor junior CNC programmers, sharing knowledge and best practices to enhance their skills and contribute to team productivity

- Stay updated with industry trends and emerging technologies related to CNC programming, attending conferences and workshops to expand knowledge and stay competitive

- Implement lean manufacturing principles in the CNC programming process, reducing waste and improving overall efficiency

Frequently Asked Questions (FAQ’s) For CNC Programmer (Computer Numerical Control Programmer)

What is the role of a CNC Programmer?

A CNC Programmer is responsible for developing and implementing CNC programs that automate the production of complex parts. They use advanced CNC software tools to optimize toolpaths and improve machining efficiency. CNC Programmers also monitor and maintain CNC machines, perform preventive maintenance and troubleshooting, and train and mentor junior CNC programmers.

What skills are required to be a CNC Programmer?

CNC Programmers typically have a Bachelor’s degree in Mechanical Engineering or a related field. They have a strong knowledge of CNC programming techniques, machine maintenance, and industry best practices. CNC Programmers also have excellent communication and interpersonal skills.

What are the career prospects for CNC Programmers?

CNC Programmers are in high demand due to the increasing use of CNC machines in manufacturing. CNC Programmers can advance their careers by becoming CNC Supervisors, CNC Engineers, or Manufacturing Managers.

What is the salary range for CNC Programmers?

The salary range for CNC Programmers varies depending on experience, location, and company size. However, CNC Programmers typically earn a competitive salary and benefits package.

What is the job outlook for CNC Programmers?

The job outlook for CNC Programmers is expected to be excellent over the next decade. This is due to the increasing use of CNC machines in manufacturing and the growing demand for CNC Programmers.

What are the benefits of working as a CNC Programmer?

CNC Programmers enjoy a number of benefits, including a competitive salary and benefits package, job security, and the opportunity to work with cutting-edge technology.