Are you a seasoned Programmable Logic Controller Technician (PLC Technician) seeking a new career path? Discover our professionally built Programmable Logic Controller Technician (PLC Technician) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

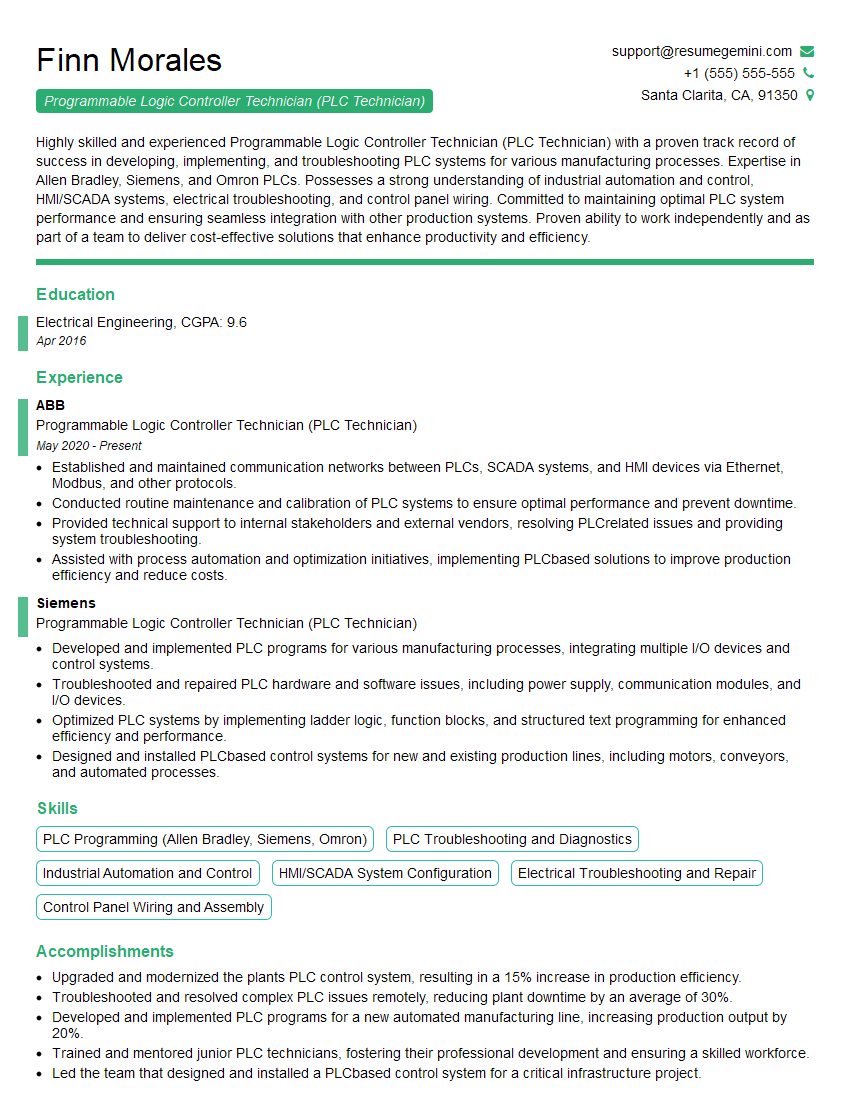

Finn Morales

Programmable Logic Controller Technician (PLC Technician)

Summary

Highly skilled and experienced Programmable Logic Controller Technician (PLC Technician) with a proven track record of success in developing, implementing, and troubleshooting PLC systems for various manufacturing processes. Expertise in Allen Bradley, Siemens, and Omron PLCs. Possesses a strong understanding of industrial automation and control, HMI/SCADA systems, electrical troubleshooting, and control panel wiring. Committed to maintaining optimal PLC system performance and ensuring seamless integration with other production systems. Proven ability to work independently and as part of a team to deliver cost-effective solutions that enhance productivity and efficiency.

Education

Electrical Engineering

April 2016

Skills

- PLC Programming (Allen Bradley, Siemens, Omron)

- PLC Troubleshooting and Diagnostics

- Industrial Automation and Control

- HMI/SCADA System Configuration

- Electrical Troubleshooting and Repair

- Control Panel Wiring and Assembly

Work Experience

Programmable Logic Controller Technician (PLC Technician)

- Established and maintained communication networks between PLCs, SCADA systems, and HMI devices via Ethernet, Modbus, and other protocols.

- Conducted routine maintenance and calibration of PLC systems to ensure optimal performance and prevent downtime.

- Provided technical support to internal stakeholders and external vendors, resolving PLCrelated issues and providing system troubleshooting.

- Assisted with process automation and optimization initiatives, implementing PLCbased solutions to improve production efficiency and reduce costs.

Programmable Logic Controller Technician (PLC Technician)

- Developed and implemented PLC programs for various manufacturing processes, integrating multiple I/O devices and control systems.

- Troubleshooted and repaired PLC hardware and software issues, including power supply, communication modules, and I/O devices.

- Optimized PLC systems by implementing ladder logic, function blocks, and structured text programming for enhanced efficiency and performance.

- Designed and installed PLCbased control systems for new and existing production lines, including motors, conveyors, and automated processes.

Accomplishments

- Upgraded and modernized the plants PLC control system, resulting in a 15% increase in production efficiency.

- Troubleshooted and resolved complex PLC issues remotely, reducing plant downtime by an average of 30%.

- Developed and implemented PLC programs for a new automated manufacturing line, increasing production output by 20%.

- Trained and mentored junior PLC technicians, fostering their professional development and ensuring a skilled workforce.

- Led the team that designed and installed a PLCbased control system for a critical infrastructure project.

Awards

- Received the PLC Technician of the Year Award from the International Society of Automation (ISA).

- Recognized by the PLC Manufacturers Association for outstanding contributions to the industry.

- Awarded the Certified Master PLC Technician (CMPT) credential from the National Institute for Certification in Engineering Technologies (NICET).

- Honored with the PLC Technician Excellence Award from the American Society for Engineering Education (ASEE).

Certificates

- Certified Automation Professional (CAP)

- Certified Control Systems Technician (CCST)

- Certified Machine Safety Expert (CMSE)

- Certified Programmable Logic Controller (PLC) Technician

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Programmable Logic Controller Technician (PLC Technician)

- Highlight your technical skills and experience in PLC programming, troubleshooting, and industrial automation.

- Quantify your accomplishments and provide specific examples of how you have improved productivity or efficiency through your work.

- Showcase your knowledge of different PLC brands and industry-specific applications.

- Include any certifications or training programs you have completed to demonstrate your commitment to professional development.

- Proofread your resume carefully for any errors and ensure it is well-organized and easy to read.

Essential Experience Highlights for a Strong Programmable Logic Controller Technician (PLC Technician) Resume

- Develop and implement PLC programs for various manufacturing processes, integrating multiple I/O devices and control systems.

- Troubleshoot and repair PLC hardware and software issues, including power supply, communication modules, and I/O devices.

- Optimize PLC systems by implementing ladder logic, function blocks, and structured text programming for enhanced efficiency and performance.

- Design and install PLCbased control systems for new and existing production lines, including motors, conveyors, and automated processes.

- Provide technical support to internal stakeholders and external vendors, resolving PLC-related issues and providing system troubleshooting.

Frequently Asked Questions (FAQ’s) For Programmable Logic Controller Technician (PLC Technician)

What are the primary responsibilities of a PLC Technician?

PLC Technicians are responsible for programming, installing, maintaining, and troubleshooting PLC systems used in industrial automation. They work closely with engineers and other technicians to ensure that PLCs are operating efficiently and effectively.

What are the key skills required for a PLC Technician?

PLC Technicians should have a strong understanding of electrical engineering, PLC programming, and industrial automation. They should also be proficient in troubleshooting and repairing PLC hardware and software.

What are the career prospects for PLC Technicians?

The demand for PLC Technicians is expected to grow in the coming years as more and more industries adopt automation. PLC Technicians with strong skills and experience can advance to positions such as Automation Engineer or Control Systems Engineer.

What are the different types of PLC systems?

There are many different types of PLC systems available, each with its own unique features and capabilities. Some of the most common types of PLC systems include: compact PLCs, modular PLCs, and rack-based PLCs.

What are the benefits of using PLC systems in industrial automation?

PLC systems offer a number of benefits in industrial automation, including: increased productivity, improved efficiency, reduced downtime, and enhanced safety.