Are you a seasoned Production Technician, Semiconductor Processing Equipment seeking a new career path? Discover our professionally built Production Technician, Semiconductor Processing Equipment Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

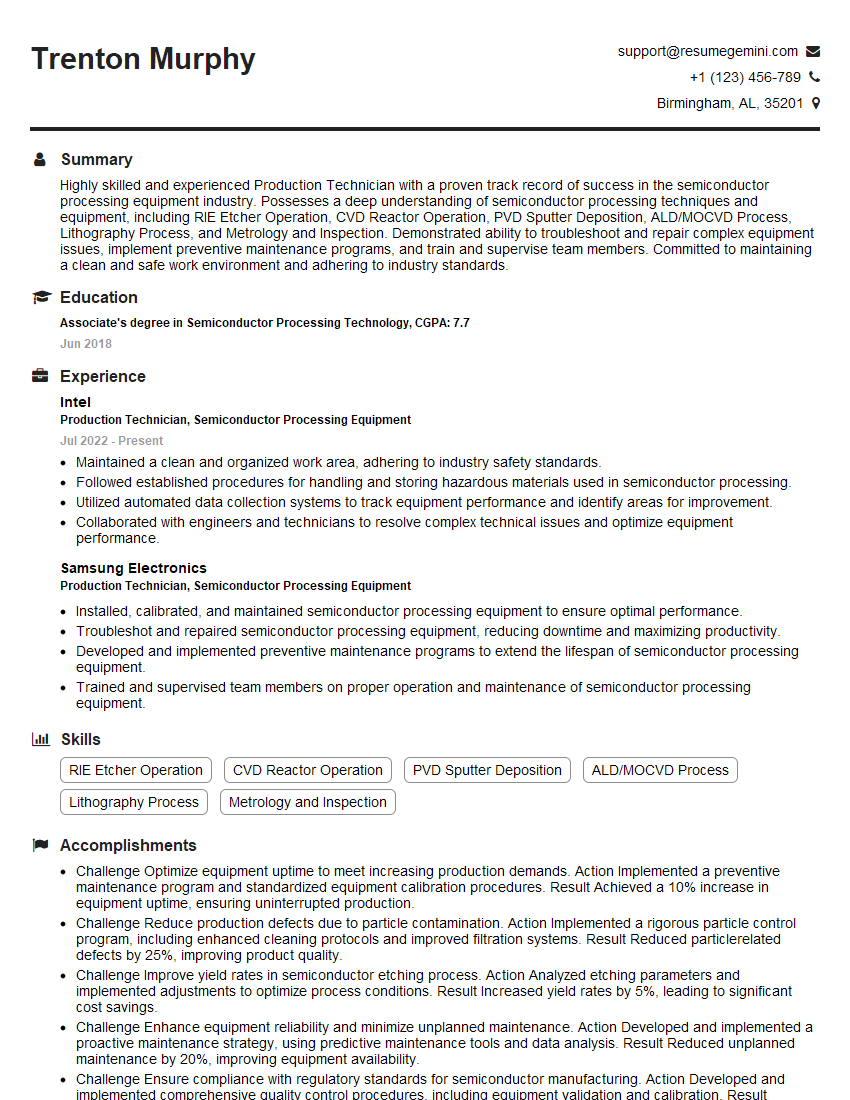

Trenton Murphy

Production Technician, Semiconductor Processing Equipment

Summary

Highly skilled and experienced Production Technician with a proven track record of success in the semiconductor processing equipment industry. Possesses a deep understanding of semiconductor processing techniques and equipment, including RIE Etcher Operation, CVD Reactor Operation, PVD Sputter Deposition, ALD/MOCVD Process, Lithography Process, and Metrology and Inspection. Demonstrated ability to troubleshoot and repair complex equipment issues, implement preventive maintenance programs, and train and supervise team members. Committed to maintaining a clean and safe work environment and adhering to industry standards.

Education

Associate’s degree in Semiconductor Processing Technology

June 2018

Skills

- RIE Etcher Operation

- CVD Reactor Operation

- PVD Sputter Deposition

- ALD/MOCVD Process

- Lithography Process

- Metrology and Inspection

Work Experience

Production Technician, Semiconductor Processing Equipment

- Maintained a clean and organized work area, adhering to industry safety standards.

- Followed established procedures for handling and storing hazardous materials used in semiconductor processing.

- Utilized automated data collection systems to track equipment performance and identify areas for improvement.

- Collaborated with engineers and technicians to resolve complex technical issues and optimize equipment performance.

Production Technician, Semiconductor Processing Equipment

- Installed, calibrated, and maintained semiconductor processing equipment to ensure optimal performance.

- Troubleshot and repaired semiconductor processing equipment, reducing downtime and maximizing productivity.

- Developed and implemented preventive maintenance programs to extend the lifespan of semiconductor processing equipment.

- Trained and supervised team members on proper operation and maintenance of semiconductor processing equipment.

Accomplishments

- Challenge Optimize equipment uptime to meet increasing production demands. Action Implemented a preventive maintenance program and standardized equipment calibration procedures. Result Achieved a 10% increase in equipment uptime, ensuring uninterrupted production.

- Challenge Reduce production defects due to particle contamination. Action Implemented a rigorous particle control program, including enhanced cleaning protocols and improved filtration systems. Result Reduced particlerelated defects by 25%, improving product quality.

- Challenge Improve yield rates in semiconductor etching process. Action Analyzed etching parameters and implemented adjustments to optimize process conditions. Result Increased yield rates by 5%, leading to significant cost savings.

- Challenge Enhance equipment reliability and minimize unplanned maintenance. Action Developed and implemented a proactive maintenance strategy, using predictive maintenance tools and data analysis. Result Reduced unplanned maintenance by 20%, improving equipment availability.

- Challenge Ensure compliance with regulatory standards for semiconductor manufacturing. Action Developed and implemented comprehensive quality control procedures, including equipment validation and calibration. Result Maintained 100% compliance with industry standards, ensuring product safety and reliability.

Awards

- Recognized for outstanding performance in maintaining a defectfree production line for over six consecutive months.

- Received the Technician of the Year award for implementing innovative maintenance techniques that reduced equipment downtime by 15%.

- Honored with the Safety Excellence award for consistently adhering to stringent safety protocols and contributing to a safe work environment.

Certificates

- Certified Production Technician (CPT)

- ASML Equipment Certification

- Lam Research Equipment Certification

- TEL Equipment Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Technician, Semiconductor Processing Equipment

- Highlight your technical skills and experience in semiconductor processing equipment.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Showcase your ability to work independently and as part of a team.

- Emphasize your commitment to safety and quality.

Essential Experience Highlights for a Strong Production Technician, Semiconductor Processing Equipment Resume

- Installed, calibrated, and maintained semiconductor processing equipment to ensure optimal performance.

- Troubleshot and repaired semiconductor processing equipment, reducing downtime and maximizing productivity.

- Developed and implemented preventive maintenance programs to extend the lifespan of semiconductor processing equipment.

- Trained and supervised team members on proper operation and maintenance of semiconductor processing equipment.

- Maintained a clean and organized work area, adhering to industry safety standards.

- Followed established procedures for handling and storing hazardous materials used in semiconductor processing.

- Utilized automated data collection systems to track equipment performance and identify areas for improvement.

Frequently Asked Questions (FAQ’s) For Production Technician, Semiconductor Processing Equipment

What are the key responsibilities of a Production Technician, Semiconductor Processing Equipment?

Key responsibilities include installing, calibrating, and maintaining semiconductor processing equipment, troubleshooting and repairing equipment, developing and implementing preventive maintenance programs, training and supervising team members, and maintaining a clean and safe work environment.

What are the educational requirements for a Production Technician, Semiconductor Processing Equipment?

Typically, an associate’s degree in Semiconductor Processing Technology or a related field is required.

What are the career prospects for a Production Technician, Semiconductor Processing Equipment?

With experience and additional training, Production Technicians can advance to roles such as Process Engineer, Maintenance Supervisor, or Quality Control Manager.

What are the key skills required for a Production Technician, Semiconductor Processing Equipment?

Key skills include knowledge of semiconductor processing techniques and equipment, troubleshooting and repair skills, preventive maintenance skills, and the ability to work independently and as part of a team.

What is the work environment like for a Production Technician, Semiconductor Processing Equipment?

Production Technicians typically work in cleanrooms or other controlled environments and may be exposed to hazardous materials. They must be able to work independently and follow established procedures carefully.

What are the salary expectations for a Production Technician, Semiconductor Processing Equipment?

Salary expectations vary depending on experience, location, and company size, but Production Technicians with several years of experience can earn a competitive salary and benefits package.

What are the growth opportunities for a Production Technician, Semiconductor Processing Equipment?

With experience and additional training, Production Technicians can advance to roles such as Process Engineer, Maintenance Supervisor, or Quality Control Manager. They may also pursue further education to earn a bachelor’s or master’s degree in a related field.