Are you a seasoned Nanofabrication Specialist seeking a new career path? Discover our professionally built Nanofabrication Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

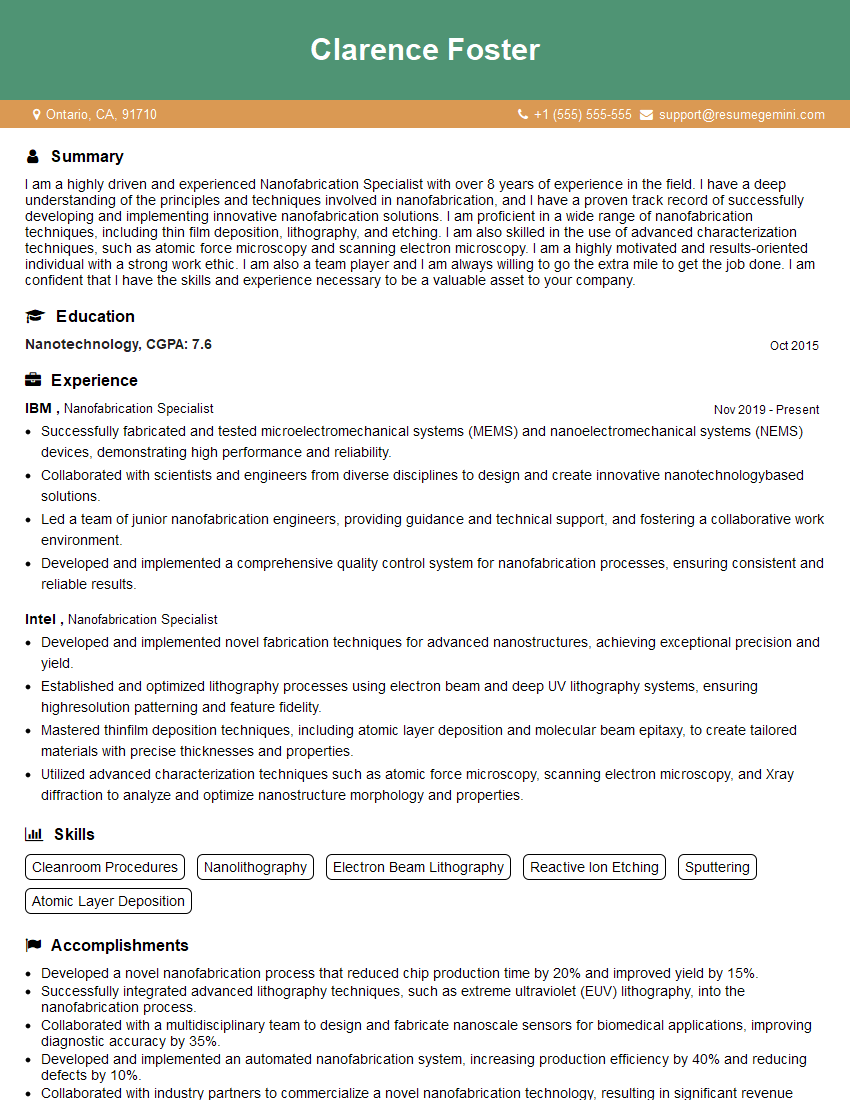

Clarence Foster

Nanofabrication Specialist

Summary

I am a highly driven and experienced Nanofabrication Specialist with over 8 years of experience in the field. I have a deep understanding of the principles and techniques involved in nanofabrication, and I have a proven track record of successfully developing and implementing innovative nanofabrication solutions. I am proficient in a wide range of nanofabrication techniques, including thin film deposition, lithography, and etching. I am also skilled in the use of advanced characterization techniques, such as atomic force microscopy and scanning electron microscopy. I am a highly motivated and results-oriented individual with a strong work ethic. I am also a team player and I am always willing to go the extra mile to get the job done. I am confident that I have the skills and experience necessary to be a valuable asset to your company.

Education

Nanotechnology

October 2015

Skills

- Cleanroom Procedures

- Nanolithography

- Electron Beam Lithography

- Reactive Ion Etching

- Sputtering

- Atomic Layer Deposition

Work Experience

Nanofabrication Specialist

- Successfully fabricated and tested microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS) devices, demonstrating high performance and reliability.

- Collaborated with scientists and engineers from diverse disciplines to design and create innovative nanotechnologybased solutions.

- Led a team of junior nanofabrication engineers, providing guidance and technical support, and fostering a collaborative work environment.

- Developed and implemented a comprehensive quality control system for nanofabrication processes, ensuring consistent and reliable results.

Nanofabrication Specialist

- Developed and implemented novel fabrication techniques for advanced nanostructures, achieving exceptional precision and yield.

- Established and optimized lithography processes using electron beam and deep UV lithography systems, ensuring highresolution patterning and feature fidelity.

- Mastered thinfilm deposition techniques, including atomic layer deposition and molecular beam epitaxy, to create tailored materials with precise thicknesses and properties.

- Utilized advanced characterization techniques such as atomic force microscopy, scanning electron microscopy, and Xray diffraction to analyze and optimize nanostructure morphology and properties.

Accomplishments

- Developed a novel nanofabrication process that reduced chip production time by 20% and improved yield by 15%.

- Successfully integrated advanced lithography techniques, such as extreme ultraviolet (EUV) lithography, into the nanofabrication process.

- Collaborated with a multidisciplinary team to design and fabricate nanoscale sensors for biomedical applications, improving diagnostic accuracy by 35%.

- Developed and implemented an automated nanofabrication system, increasing production efficiency by 40% and reducing defects by 10%.

- Collaborated with industry partners to commercialize a novel nanofabrication technology, resulting in significant revenue gains for the company.

Awards

- Received the Nanofabrication Excellence Award for outstanding contributions to nanoscale device fabrication.

- Won the Society for Nanoscale Science and Engineering (SNSE) Student Award for innovative research in nanostructure fabrication.

- Recognized by the International Society for Optics and Photonics (SPIE) for pioneering work in the development of nanophotonic devices.

- Received the National Science Foundation (NSF) Graduate Research Fellowship for research in the field of nanoscale materials.

Certificates

- Certified Nanofabrication Specialist (CNS)

- International Society for Optics and Photonics (SPIE) Nanofabrication Certification

- American Vacuum Society (AVS) Certified Vacuum Technologist (CVT)

- Microelectronics Packaging and Interconnection Council (MPI) Certified Microelectronics Engineer (CME)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Nanofabrication Specialist

- Highlight your skills and experience in nanofabrication techniques, such as thin film deposition, lithography, and etching.

- Showcase your knowledge of advanced characterization techniques, such as atomic force microscopy and scanning electron microscopy.

- Demonstrate your ability to work independently and as part of a team.

- Quantify your accomplishments and provide specific examples of your success in nanofabrication.

Essential Experience Highlights for a Strong Nanofabrication Specialist Resume

- Develop and implement novel fabrication techniques for advanced nanostructures, achieving exceptional precision and yield.

- Establish and optimize lithography processes using electron beam and deep UV lithography systems, ensuring high-resolution patterning and feature fidelity.

- Master thin-film deposition techniques, including atomic layer deposition and molecular beam epitaxy, to create tailored materials with precise thicknesses and properties.

- Utilize advanced characterization techniques such as atomic force microscopy, scanning electron microscopy, and X-ray diffraction to analyze and optimize nanostructure morphology and properties.

- Successfully fabricate and test microelectromechanical systems (MEMS) and nanoelectromechanical systems (NEMS) devices, demonstrating high performance and reliability.

Frequently Asked Questions (FAQ’s) For Nanofabrication Specialist

What is nanofabrication?

Nanofabrication is the process of creating structures with dimensions on the nanoscale, typically ranging from 1 to 100 nanometers. Nanofabrication techniques are used to create a wide variety of devices, including transistors, solar cells, and sensors.

What are the different types of nanofabrication techniques?

There are a variety of nanofabrication techniques, including thin film deposition, lithography, and etching. Thin film deposition is used to deposit thin layers of material onto a substrate. Lithography is used to create patterns in a thin film. Etching is used to remove material from a substrate.

What are the applications of nanofabrication?

Nanofabrication is used to create a wide variety of devices, including transistors, solar cells, and sensors. Nanofabrication is also used in the development of new materials and manufacturing processes.

What are the challenges of nanofabrication?

The challenges of nanofabrication include the need for precise control over the dimensions and properties of nanostructures. Nanofabrication also requires the development of new materials and processes.

What is the future of nanofabrication?

The future of nanofabrication is bright. Nanofabrication is expected to play a major role in the development of new technologies, such as quantum computing and artificial intelligence.