Are you a seasoned Instrument Man (I-Man) seeking a new career path? Discover our professionally built Instrument Man (I-Man) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

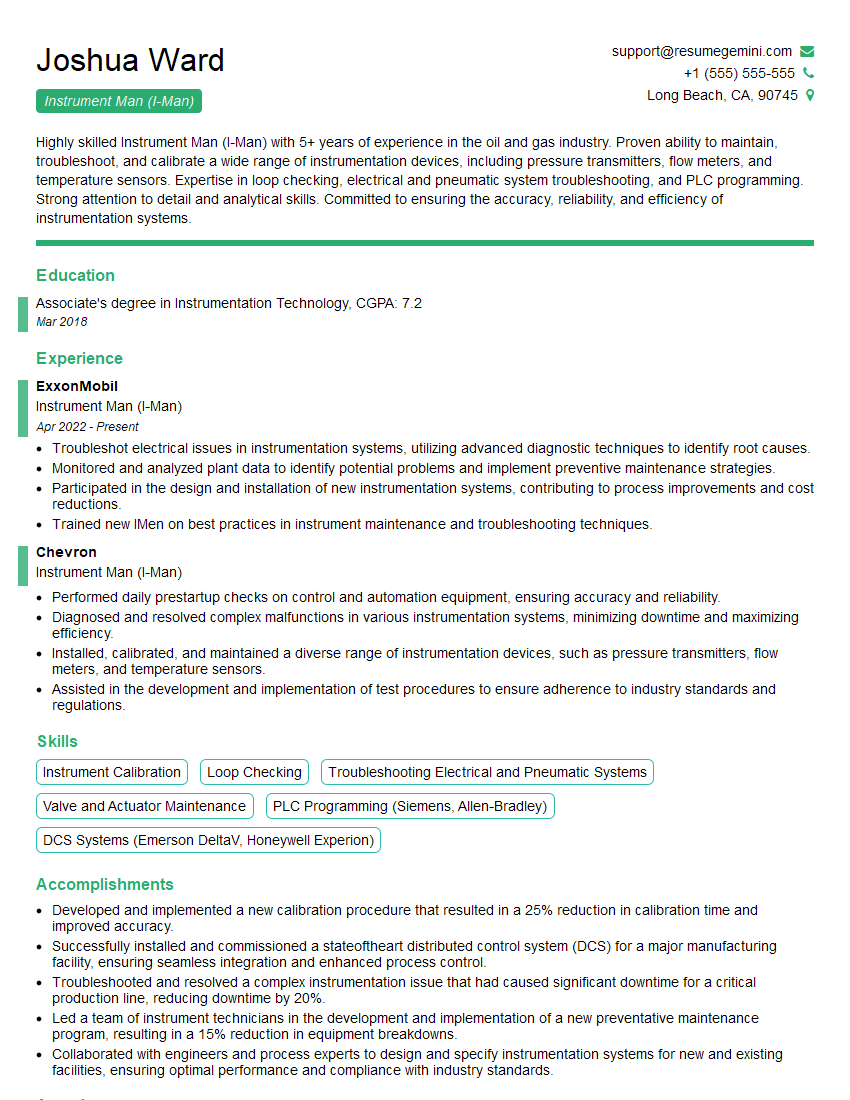

Joshua Ward

Instrument Man (I-Man)

Summary

Highly skilled Instrument Man (I-Man) with 5+ years of experience in the oil and gas industry. Proven ability to maintain, troubleshoot, and calibrate a wide range of instrumentation devices, including pressure transmitters, flow meters, and temperature sensors. Expertise in loop checking, electrical and pneumatic system troubleshooting, and PLC programming. Strong attention to detail and analytical skills. Committed to ensuring the accuracy, reliability, and efficiency of instrumentation systems.

Education

Associate’s degree in Instrumentation Technology

March 2018

Skills

- Instrument Calibration

- Loop Checking

- Troubleshooting Electrical and Pneumatic Systems

- Valve and Actuator Maintenance

- PLC Programming (Siemens, Allen-Bradley)

- DCS Systems (Emerson DeltaV, Honeywell Experion)

Work Experience

Instrument Man (I-Man)

- Troubleshot electrical issues in instrumentation systems, utilizing advanced diagnostic techniques to identify root causes.

- Monitored and analyzed plant data to identify potential problems and implement preventive maintenance strategies.

- Participated in the design and installation of new instrumentation systems, contributing to process improvements and cost reductions.

- Trained new IMen on best practices in instrument maintenance and troubleshooting techniques.

Instrument Man (I-Man)

- Performed daily prestartup checks on control and automation equipment, ensuring accuracy and reliability.

- Diagnosed and resolved complex malfunctions in various instrumentation systems, minimizing downtime and maximizing efficiency.

- Installed, calibrated, and maintained a diverse range of instrumentation devices, such as pressure transmitters, flow meters, and temperature sensors.

- Assisted in the development and implementation of test procedures to ensure adherence to industry standards and regulations.

Accomplishments

- Developed and implemented a new calibration procedure that resulted in a 25% reduction in calibration time and improved accuracy.

- Successfully installed and commissioned a stateoftheart distributed control system (DCS) for a major manufacturing facility, ensuring seamless integration and enhanced process control.

- Troubleshooted and resolved a complex instrumentation issue that had caused significant downtime for a critical production line, reducing downtime by 20%.

- Led a team of instrument technicians in the development and implementation of a new preventative maintenance program, resulting in a 15% reduction in equipment breakdowns.

- Collaborated with engineers and process experts to design and specify instrumentation systems for new and existing facilities, ensuring optimal performance and compliance with industry standards.

Awards

- Received the Instrument Man of the Year Award for exceptional performance in calibration, installation, and maintenance of instrumentation systems.

- Recognized with the Safety Excellence Award for consistently adhering to safety protocols and implementing innovative techniques to enhance workplace safety.

- Awarded the Team Excellence Award for outstanding collaboration and leadership in completing a complex instrumentation project under tight deadlines.

Certificates

- Certified Instrument Technician (CIT)

- ISA Certified Automation Professional (CAP)

- Commissioning Specialist Certification (CSC)

- ASME B31.3 Process Piping Code Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Instrument Man (I-Man)

- Highlight your experience and skills in a clear and concise manner.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Tailor your resume to each specific job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Instrument Man (I-Man) Resume

- Performed daily prestartup checks on control and automation equipment, ensuring accuracy and reliability.

- Diagnosed and resolved complex malfunctions in various instrumentation systems, minimizing downtime and maximizing efficiency.

- Installed, calibrated, and maintained a diverse range of instrumentation devices, such as pressure transmitters, flow meters, and temperature sensors.

- Assisted in the development and implementation of test procedures to ensure adherence to industry standards and regulations.

- Troubleshot electrical issues in instrumentation systems, utilizing advanced diagnostic techniques to identify root causes.

- Monitored and analyzed plant data to identify potential problems and implement preventive maintenance strategies.

- Participated in the design and installation of new instrumentation systems, contributing to process improvements and cost reductions.

Frequently Asked Questions (FAQ’s) For Instrument Man (I-Man)

What is the role of an Instrument Man (I-Man)?

An Instrument Man (I-Man) is responsible for the maintenance, calibration, and troubleshooting of instrumentation devices in a variety of industries, including oil and gas, manufacturing, and power generation.

What are the key skills required for an Instrument Man (I-Man)?

Key skills for an Instrument Man (I-Man) include proficiency in loop checking, electrical and pneumatic system troubleshooting, PLC programming, and the ability to read and interpret technical diagrams.

What are the career prospects for an Instrument Man (I-Man)?

Instrument Men (I-Men) with experience and expertise can advance to roles such as Instrument Technician, Instrumentation Engineer, or Maintenance Supervisor.

What are the challenges faced by an Instrument Man (I-Man)?

Instrument Men (I-Men) may face challenges such as working in hazardous environments, dealing with complex technical issues, and being on call for emergencies.

What are the typical working conditions for an Instrument Man (I-Man)?

Instrument Men (I-Men) typically work in industrial settings, such as factories, power plants, and oil and gas facilities. They may work indoors or outdoors, and may be required to work in confined spaces or at heights.