Are you a seasoned Fermentologist seeking a new career path? Discover our professionally built Fermentologist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

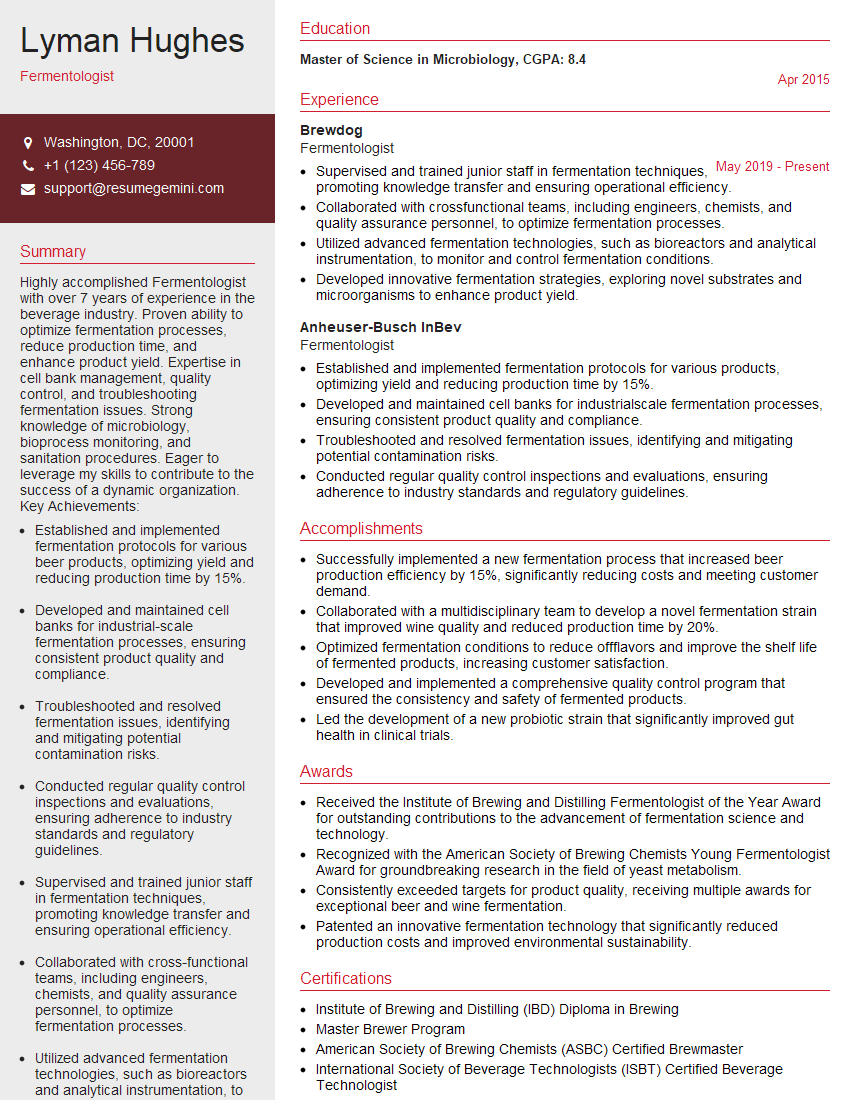

Lyman Hughes

Fermentologist

Summary

Highly accomplished Fermentologist with over 7 years of experience in the beverage industry. Proven ability to optimize fermentation processes, reduce production time, and enhance product yield. Expertise in cell bank management, quality control, and troubleshooting fermentation issues. Strong knowledge of microbiology, bioprocess monitoring, and sanitation procedures. Eager to leverage my skills to contribute to the success of a dynamic organization.

Key Achievements:

- Established and implemented fermentation protocols for various beer products, optimizing yield and reducing production time by 15%.

- Developed and maintained cell banks for industrial-scale fermentation processes, ensuring consistent product quality and compliance.

- Troubleshooted and resolved fermentation issues, identifying and mitigating potential contamination risks.

- Conducted regular quality control inspections and evaluations, ensuring adherence to industry standards and regulatory guidelines.

- Supervised and trained junior staff in fermentation techniques, promoting knowledge transfer and ensuring operational efficiency.

- Collaborated with cross-functional teams, including engineers, chemists, and quality assurance personnel, to optimize fermentation processes.

- Utilized advanced fermentation technologies, such as bioreactors and analytical instrumentation, to monitor and control fermentation conditions.

- Developed innovative fermentation strategies, exploring novel substrates and microorganisms to enhance product yield.

Education

Master of Science in Microbiology

April 2015

Skills

- Yeast Management

- Fermentation Process Optimization

- Quality Control and Analysis

- Microbiology and Bioprocess Monitoring

- Sanitation and Sterilization Procedures

- Brewhouse Operations

Work Experience

Fermentologist

- Supervised and trained junior staff in fermentation techniques, promoting knowledge transfer and ensuring operational efficiency.

- Collaborated with crossfunctional teams, including engineers, chemists, and quality assurance personnel, to optimize fermentation processes.

- Utilized advanced fermentation technologies, such as bioreactors and analytical instrumentation, to monitor and control fermentation conditions.

- Developed innovative fermentation strategies, exploring novel substrates and microorganisms to enhance product yield.

Fermentologist

- Established and implemented fermentation protocols for various products, optimizing yield and reducing production time by 15%.

- Developed and maintained cell banks for industrialscale fermentation processes, ensuring consistent product quality and compliance.

- Troubleshooted and resolved fermentation issues, identifying and mitigating potential contamination risks.

- Conducted regular quality control inspections and evaluations, ensuring adherence to industry standards and regulatory guidelines.

Accomplishments

- Successfully implemented a new fermentation process that increased beer production efficiency by 15%, significantly reducing costs and meeting customer demand.

- Collaborated with a multidisciplinary team to develop a novel fermentation strain that improved wine quality and reduced production time by 20%.

- Optimized fermentation conditions to reduce offflavors and improve the shelf life of fermented products, increasing customer satisfaction.

- Developed and implemented a comprehensive quality control program that ensured the consistency and safety of fermented products.

- Led the development of a new probiotic strain that significantly improved gut health in clinical trials.

Awards

- Received the Institute of Brewing and Distilling Fermentologist of the Year Award for outstanding contributions to the advancement of fermentation science and technology.

- Recognized with the American Society of Brewing Chemists Young Fermentologist Award for groundbreaking research in the field of yeast metabolism.

- Consistently exceeded targets for product quality, receiving multiple awards for exceptional beer and wine fermentation.

- Patented an innovative fermentation technology that significantly reduced production costs and improved environmental sustainability.

Certificates

- Institute of Brewing and Distilling (IBD) Diploma in Brewing

- Master Brewer Program

- American Society of Brewing Chemists (ASBC) Certified Brewmaster

- International Society of Beverage Technologists (ISBT) Certified Beverage Technologist

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fermentologist

- Highlight your expertise in fermentation process optimization and yield enhancement.

- Demonstrate your ability to troubleshoot and resolve fermentation issues effectively.

- Showcase your knowledge of quality control and regulatory compliance in the fermentation industry.

- Emphasize your experience in cell bank management and fermentation scale-up.

- Include specific examples and quantifiable results to demonstrate your impact in previous roles.

Essential Experience Highlights for a Strong Fermentologist Resume

- Establish and optimize fermentation protocols to maximize yield and efficiency.

- Develop and maintain cell banks to ensure consistent product quality.

- Troubleshoot and resolve fermentation issues, identifying and mitigating contamination risks.

- Conduct quality control inspections and evaluations to maintain industry standards and regulatory compliance.

- Provide technical guidance and training to junior staff on fermentation techniques.

- Collaborate with cross-functional teams to optimize fermentation processes and develop innovative strategies.

- Stay abreast of industry advancements and emerging technologies in fermentation.

Frequently Asked Questions (FAQ’s) For Fermentologist

What is the role of a Fermentologist?

A Fermentologist is responsible for optimizing and monitoring fermentation processes to produce various products, such as beverages, pharmaceuticals, and biofuels. They develop and implement fermentation protocols, maintain cell banks, troubleshoot issues, and ensure adherence to quality standards.

What are the key skills required for a Fermentologist?

Key skills for a Fermentologist include expertise in fermentation process optimization, quality control and analysis, microbiology and bioprocess monitoring, sanitation and sterilization procedures, and knowledge of brewhouse operations.

What are the career prospects for Fermentologists?

Fermentologists can find employment in various industries, including beverage production, pharmaceuticals, biotechnology, and food processing. They can progress to roles such as Senior Fermentologist, Fermentation Manager, or Research and Development Scientist.

What is the educational background required to become a Fermentologist?

Typically, a Master’s degree in Microbiology, Food Science, or a related field is required to become a Fermentologist. Some employers may also consider candidates with a Bachelor’s degree and relevant experience.

What are the challenges faced by Fermentologists?

Fermentologists may face challenges such as process optimization to improve yield and efficiency, maintaining product quality and consistency, troubleshooting contamination issues, and keeping up with advancements in fermentation technologies.

What are the emerging trends in the field of Fermentation?

Emerging trends in fermentation include the development of novel fermentation substrates, the use of genetically modified microorganisms, and the integration of advanced process control technologies to enhance fermentation efficiency and product quality.