Are you a seasoned Quality Control Tech, Raw Materials seeking a new career path? Discover our professionally built Quality Control Tech, Raw Materials Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

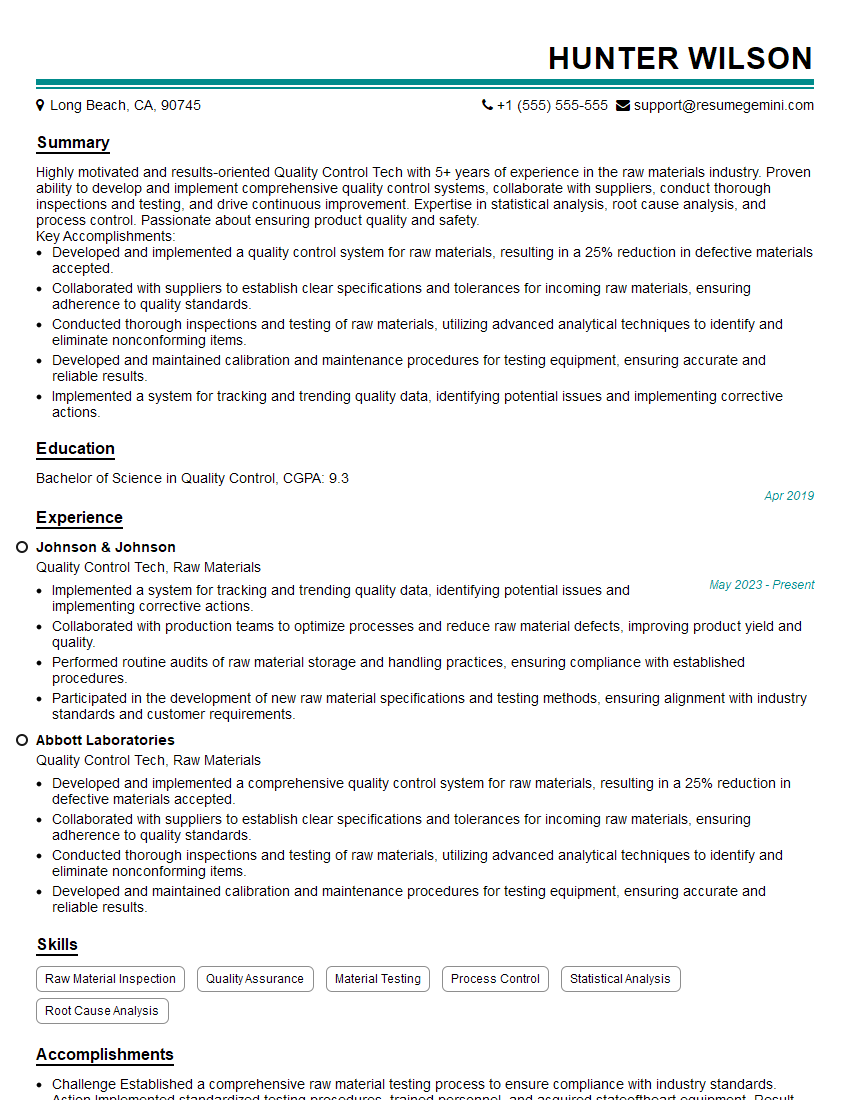

Hunter Wilson

Quality Control Tech, Raw Materials

Summary

Highly motivated and results-oriented Quality Control Tech with 5+ years of experience in the raw materials industry. Proven ability to develop and implement comprehensive quality control systems, collaborate with suppliers, conduct thorough inspections and testing, and drive continuous improvement. Expertise in statistical analysis, root cause analysis, and process control. Passionate about ensuring product quality and safety.

Key Accomplishments:

- Developed and implemented a quality control system for raw materials, resulting in a 25% reduction in defective materials accepted.

- Collaborated with suppliers to establish clear specifications and tolerances for incoming raw materials, ensuring adherence to quality standards.

- Conducted thorough inspections and testing of raw materials, utilizing advanced analytical techniques to identify and eliminate nonconforming items.

- Developed and maintained calibration and maintenance procedures for testing equipment, ensuring accurate and reliable results.

- Implemented a system for tracking and trending quality data, identifying potential issues and implementing corrective actions.

Education

Bachelor of Science in Quality Control

April 2019

Skills

- Raw Material Inspection

- Quality Assurance

- Material Testing

- Process Control

- Statistical Analysis

- Root Cause Analysis

Work Experience

Quality Control Tech, Raw Materials

- Implemented a system for tracking and trending quality data, identifying potential issues and implementing corrective actions.

- Collaborated with production teams to optimize processes and reduce raw material defects, improving product yield and quality.

- Performed routine audits of raw material storage and handling practices, ensuring compliance with established procedures.

- Participated in the development of new raw material specifications and testing methods, ensuring alignment with industry standards and customer requirements.

Quality Control Tech, Raw Materials

- Developed and implemented a comprehensive quality control system for raw materials, resulting in a 25% reduction in defective materials accepted.

- Collaborated with suppliers to establish clear specifications and tolerances for incoming raw materials, ensuring adherence to quality standards.

- Conducted thorough inspections and testing of raw materials, utilizing advanced analytical techniques to identify and eliminate nonconforming items.

- Developed and maintained calibration and maintenance procedures for testing equipment, ensuring accurate and reliable results.

Accomplishments

- Challenge Established a comprehensive raw material testing process to ensure compliance with industry standards. Action Implemented standardized testing procedures, trained personnel, and acquired stateoftheart equipment. Result Reduced nonconforming raw material shipments by 40%.

- Challenge Identified a recurring contamination issue in raw materials. Action Conducted root cause analysis and implemented corrective actions in collaboration with suppliers. Result Eliminated contamination, saving the company over $100,000 annually.

- Challenge Developed a new method for analyzing trace elements in raw materials using atomic absorption spectroscopy. Action Optimized the technique, validated the method, and implemented it in the laboratory. Result Improved detection limits, enabling earlier identification of impurities.

- Challenge Streamlined the raw material approval process without compromising quality standards. Action Automated data collection, implemented a digital workflow, and collaborated with suppliers to establish clear acceptance criteria. Result Reduced approval time by 25%.

- Challenge Implemented a vendor qualification program to ensure the reliability of raw material suppliers. Action Developed vendor assessment criteria, conducted supplier audits, and established performance monitoring metrics. Result Improved supplier quality, reduced supply chain risks.

Awards

- Received the companys Quality Excellence Award for exceptional contributions in raw material quality control.

- Recognized with the Industry Leadership Award for developing innovative methods to enhance raw material inspection efficiency.

- Awarded the Certification of Excellence in Quality Control by the American Society for Testing and Materials (ASTM).

Certificates

- Certified Quality Inspector (CQI)

- Certified Quality Auditor (CQA)

- Six Sigma Green Belt or Black Belt

- GxP Regulations Compliance Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Quality Control Tech, Raw Materials

- Highlight your experience in developing and implementing quality control systems for raw materials.

- Quantify your accomplishments whenever possible, such as reducing the number of defective materials accepted or improving product yield.

- Demonstrate your knowledge of statistical analysis, root cause analysis, and process control.

- Emphasize your ability to collaborate with suppliers and production teams to ensure quality standards are met.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Quality Control Tech, Raw Materials Resume

- Develop and implement comprehensive quality control systems for raw materials.

- Collaborate with suppliers to establish clear specifications and tolerances for incoming raw materials.

- Conduct thorough inspections and testing of raw materials, utilizing advanced analytical techniques to identify and eliminate nonconforming items.

- Develop and maintain calibration and maintenance procedures for testing equipment, ensuring accurate and reliable results.

- Implement a system for tracking and trending quality data, identifying potential issues and implementing corrective actions.

- Collaborate with production teams to optimize processes and reduce raw material defects, improving product yield and quality.

- Perform routine audits of raw material storage and handling practices, ensuring compliance with established procedures.

Frequently Asked Questions (FAQ’s) For Quality Control Tech, Raw Materials

What is the role of a Quality Control Tech, Raw Materials?

A Quality Control Tech, Raw Materials is responsible for ensuring that the raw materials used in a manufacturing process meet the required quality standards. This involves developing and implementing quality control systems, conducting inspections and testing, and collaborating with suppliers to establish specifications and tolerances.

What are the key skills and qualifications required for this role?

Key skills and qualifications for a Quality Control Tech, Raw Materials include a Bachelor’s degree in Quality Control or a related field, experience in developing and implementing quality control systems, knowledge of statistical analysis, root cause analysis, and process control, and the ability to collaborate with suppliers and production teams.

What are the career prospects for a Quality Control Tech, Raw Materials?

Quality Control Techs, Raw Materials can advance to roles such as Quality Control Manager, Quality Assurance Manager, or Production Manager. With additional experience and education, they may also pursue careers in research and development or consulting.

What are the challenges of working as a Quality Control Tech, Raw Materials?

Challenges of working as a Quality Control Tech, Raw Materials include ensuring that raw materials meet quality standards, troubleshooting and resolving quality issues, and working in a fast-paced and demanding environment.

What are the benefits of working as a Quality Control Tech, Raw Materials?

Benefits of working as a Quality Control Tech, Raw Materials include job security, opportunities for career advancement, and the satisfaction of ensuring product quality and safety.

How can I prepare for an interview for a Quality Control Tech, Raw Materials position?

To prepare for an interview for a Quality Control Tech, Raw Materials position, research the company and the position, practice answering common interview questions, and be prepared to discuss your experience and qualifications.

What are the typical working hours for a Quality Control Tech, Raw Materials?

Typical working hours for a Quality Control Tech, Raw Materials are 8:00 AM to 5:00 PM, Monday through Friday. However, overtime may be required to meet production deadlines or to investigate quality issues.

What are the salary expectations for a Quality Control Tech, Raw Materials?

Salary expectations for a Quality Control Tech, Raw Materials vary depending on experience, qualifications, and location. According to Salary.com, the average salary for a Quality Control Tech, Raw Materials in the United States is $65,000 per year.