Are you a seasoned Engineering and Operations Director seeking a new career path? Discover our professionally built Engineering and Operations Director Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

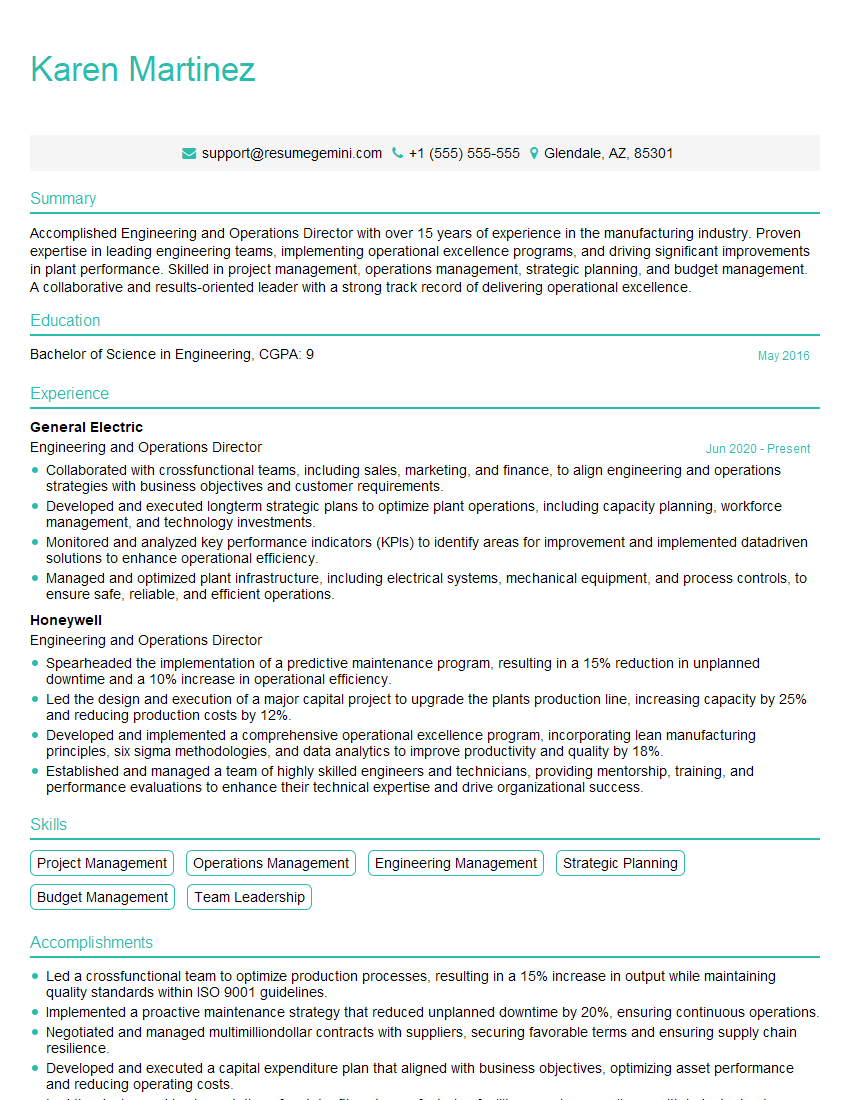

Karen Martinez

Engineering and Operations Director

Summary

Accomplished Engineering and Operations Director with over 15 years of experience in the manufacturing industry. Proven expertise in leading engineering teams, implementing operational excellence programs, and driving significant improvements in plant performance. Skilled in project management, operations management, strategic planning, and budget management. A collaborative and results-oriented leader with a strong track record of delivering operational excellence.

Education

Bachelor of Science in Engineering

May 2016

Skills

- Project Management

- Operations Management

- Engineering Management

- Strategic Planning

- Budget Management

- Team Leadership

Work Experience

Engineering and Operations Director

- Collaborated with crossfunctional teams, including sales, marketing, and finance, to align engineering and operations strategies with business objectives and customer requirements.

- Developed and executed longterm strategic plans to optimize plant operations, including capacity planning, workforce management, and technology investments.

- Monitored and analyzed key performance indicators (KPIs) to identify areas for improvement and implemented datadriven solutions to enhance operational efficiency.

- Managed and optimized plant infrastructure, including electrical systems, mechanical equipment, and process controls, to ensure safe, reliable, and efficient operations.

Engineering and Operations Director

- Spearheaded the implementation of a predictive maintenance program, resulting in a 15% reduction in unplanned downtime and a 10% increase in operational efficiency.

- Led the design and execution of a major capital project to upgrade the plants production line, increasing capacity by 25% and reducing production costs by 12%.

- Developed and implemented a comprehensive operational excellence program, incorporating lean manufacturing principles, six sigma methodologies, and data analytics to improve productivity and quality by 18%.

- Established and managed a team of highly skilled engineers and technicians, providing mentorship, training, and performance evaluations to enhance their technical expertise and drive organizational success.

Accomplishments

- Led a crossfunctional team to optimize production processes, resulting in a 15% increase in output while maintaining quality standards within ISO 9001 guidelines.

- Implemented a proactive maintenance strategy that reduced unplanned downtime by 20%, ensuring continuous operations.

- Negotiated and managed multimilliondollar contracts with suppliers, securing favorable terms and ensuring supply chain resilience.

- Developed and executed a capital expenditure plan that aligned with business objectives, optimizing asset performance and reducing operating costs.

- Led the design and implementation of a stateoftheart manufacturing facility, ensuring compliance with industry best practices and environmental regulations.

Awards

- Recognized with the Operational Excellence Award for implementing innovative strategies that enhanced efficiency by 25% and reduced production costs by 12%.

- Recipient of the Engineering Innovation Award for developing a novel automated inspection system that reduced defect rates by 30%.

- Honored with the Leadership Excellence Award for effectively managing a team of 100+ engineers and technicians, fostering a culture of innovation and productivity.

- Recipient of the Safety Excellence Award for implementing comprehensive safety programs that reduced workplace accidents by 40%.

Certificates

- Project Management Professional (PMP)

- Certified Six Sigma Black Belt (CSSBB)

- Certified Lean Manufacturing Manager (CLMM)

- Certified Maintenance and Reliability Professional (CMRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Engineering and Operations Director

- Highlight your accomplishments and quantify the results of your efforts with specific metrics.

- Demonstrate your ability to drive operational excellence by implementing lean manufacturing principles and six sigma methodologies.

- Showcase your project management and leadership skills by describing successful projects you have led.

- Emphasize your experience in managing and optimizing plant infrastructure, including electrical systems, mechanical equipment, and process controls.

Essential Experience Highlights for a Strong Engineering and Operations Director Resume

- Spearhead the implementation of predictive maintenance programs to improve plant reliability and reduce downtime.

- Lead the design and execution of major capital projects to upgrade production lines, increase capacity, and reduce production costs.

- Develop and implement operational excellence programs incorporating lean manufacturing principles, six sigma methodologies, and data analytics to drive productivity and quality improvements.

- Establish and manage high-performing teams of engineers and technicians, provide mentorship and training, and conduct performance evaluations to enhance technical expertise and organizational success.

- Collaborate with cross-functional teams, including sales, marketing, and finance, to align engineering and operations strategies with business objectives and customer requirements.

- Develop and execute long-term strategic plans to optimize plant operations, including capacity planning, workforce management, and technology investments.

- Monitor and analyze key performance indicators (KPIs) to identify areas for improvement and implement data-driven solutions to enhance operational efficiency.

Frequently Asked Questions (FAQ’s) For Engineering and Operations Director

What is the primary role of an Engineering and Operations Director?

An Engineering and Operations Director is responsible for overseeing all aspects of engineering and operations within a manufacturing facility, with a focus on optimizing plant performance, improving efficiency, and driving continuous improvement.

What are the key skills and qualifications required for this role?

The ideal candidate will possess a strong technical background in engineering, along with experience in project management, operations management, strategic planning, and budget management.

What are the career advancement opportunities for an Engineering and Operations Director?

With experience and success in the role, Engineering and Operations Directors can advance to senior leadership positions such as Plant Manager or Vice President of Operations.

What are the challenges faced by Engineering and Operations Directors?

Some common challenges include managing complex production processes, ensuring regulatory compliance, and adapting to technological advancements in the manufacturing industry.

What are the best practices for Engineering and Operations Directors to achieve success?

To be successful, Engineering and Operations Directors should focus on building strong relationships with cross-functional teams, implementing data-driven decision-making, and embracing a continuous improvement mindset.

What are the emerging trends that are shaping the role of Engineering and Operations Directors?

Emerging trends include the adoption of Industry 4.0 technologies, the increasing use of data analytics for predictive maintenance, and the growing emphasis on sustainability in manufacturing operations.