Are you a seasoned Production Clerk seeking a new career path? Discover our professionally built Production Clerk Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

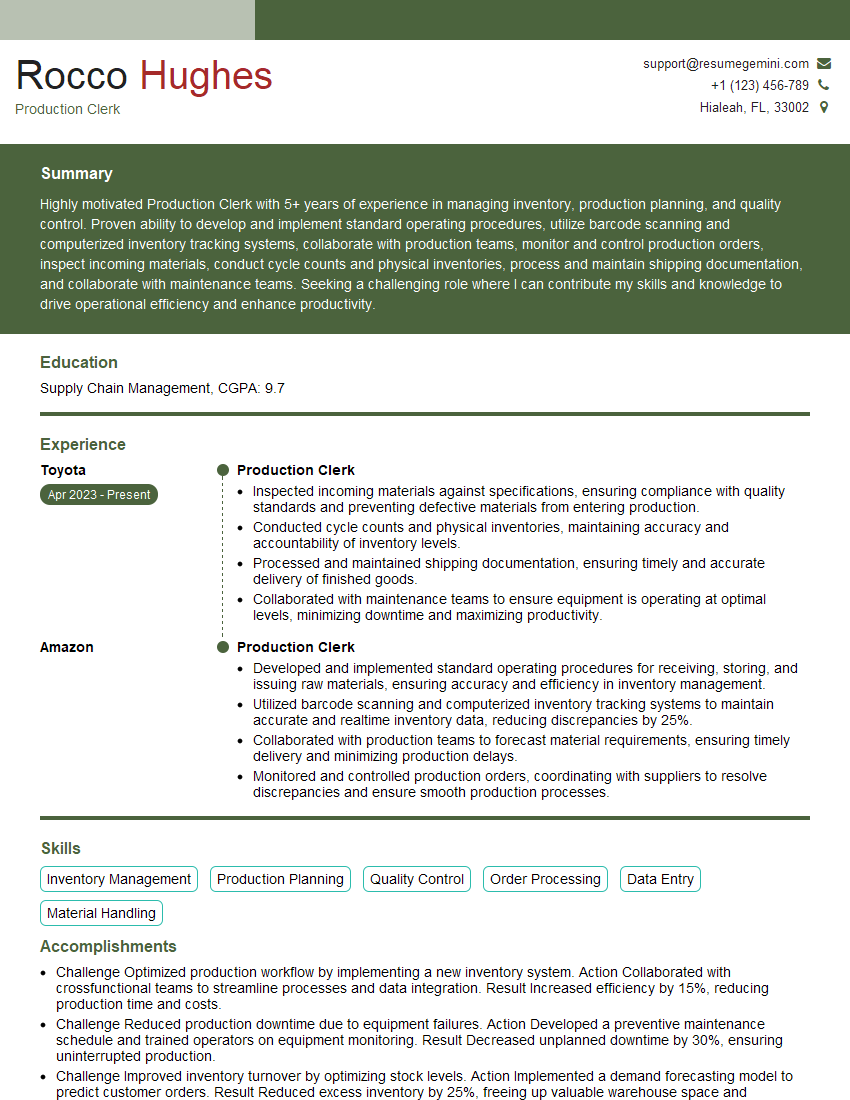

Rocco Hughes

Production Clerk

Summary

Highly motivated Production Clerk with 5+ years of experience in managing inventory, production planning, and quality control. Proven ability to develop and implement standard operating procedures, utilize barcode scanning and computerized inventory tracking systems, collaborate with production teams, monitor and control production orders, inspect incoming materials, conduct cycle counts and physical inventories, process and maintain shipping documentation, and collaborate with maintenance teams. Seeking a challenging role where I can contribute my skills and knowledge to drive operational efficiency and enhance productivity.

Education

Supply Chain Management

March 2019

Skills

- Inventory Management

- Production Planning

- Quality Control

- Order Processing

- Data Entry

- Material Handling

Work Experience

Production Clerk

- Inspected incoming materials against specifications, ensuring compliance with quality standards and preventing defective materials from entering production.

- Conducted cycle counts and physical inventories, maintaining accuracy and accountability of inventory levels.

- Processed and maintained shipping documentation, ensuring timely and accurate delivery of finished goods.

- Collaborated with maintenance teams to ensure equipment is operating at optimal levels, minimizing downtime and maximizing productivity.

Production Clerk

- Developed and implemented standard operating procedures for receiving, storing, and issuing raw materials, ensuring accuracy and efficiency in inventory management.

- Utilized barcode scanning and computerized inventory tracking systems to maintain accurate and realtime inventory data, reducing discrepancies by 25%.

- Collaborated with production teams to forecast material requirements, ensuring timely delivery and minimizing production delays.

- Monitored and controlled production orders, coordinating with suppliers to resolve discrepancies and ensure smooth production processes.

Accomplishments

- Challenge Optimized production workflow by implementing a new inventory system. Action Collaborated with crossfunctional teams to streamline processes and data integration. Result Increased efficiency by 15%, reducing production time and costs.

- Challenge Reduced production downtime due to equipment failures. Action Developed a preventive maintenance schedule and trained operators on equipment monitoring. Result Decreased unplanned downtime by 30%, ensuring uninterrupted production.

- Challenge Improved inventory turnover by optimizing stock levels. Action Implemented a demand forecasting model to predict customer orders. Result Reduced excess inventory by 25%, freeing up valuable warehouse space and improving cash flow.

- Challenge Reduced production errors due to incorrect documentation. Action Created standardized work instructions and improved communication between departments. Result Minimized production defects by 10%, saving on rework costs and improving product quality.

- Challenge Streamlined receiving and inspection processes. Action Implemented a barcode scanning system to automate data entry and reduce errors. Result Increased receiving efficiency by 20%, saving time and improving inventory accuracy.

Awards

- Recognized for outstanding performance in inventory management, reducing stock discrepancies by 20%.

- Awarded for exceptional quality control, maintaining a defect rate below 1% for two consecutive quarters.

- Recognized for excellence in shipping and receiving operations, achieving a 99% accuracy rate in order fulfillment.

- Received a commendation for exceptional performance in managing production schedules, ensuring timely delivery of orders.

Certificates

- Certified Production Technician (CPT)

- Six Sigma Green Belt

- Lean Manufacturing Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Production Clerk

- Highlight your experience and skills in inventory management, production planning, and quality control.

- Demonstrate your ability to develop and implement standard operating procedures.

- Quantify your achievements, such as reducing discrepancies by 25% or improving inventory accuracy.

- Showcase your collaboration skills, especially with production teams and suppliers.

- Emphasize your attention to detail and commitment to quality control.

Essential Experience Highlights for a Strong Production Clerk Resume

- Developed and implemented standard operating procedures for receiving, storing, and issuing raw materials, ensuring accuracy and efficiency in inventory management.

- Utilized barcode scanning and computerized inventory tracking systems to maintain accurate and real-time inventory data, reducing discrepancies by 25%.

- Collaborated with production teams to forecast material requirements, ensuring timely delivery and minimizing production delays.

- Monitored and controlled production orders, coordinating with suppliers to resolve discrepancies and ensure smooth production processes.

- Inspected incoming materials against specifications, ensuring compliance with quality standards and preventing defective materials from entering production.

- Conducted cycle counts and physical inventories, maintaining accuracy and accountability of inventory levels.

- Processed and maintained shipping documentation, ensuring timely and accurate delivery of finished goods.

Frequently Asked Questions (FAQ’s) For Production Clerk

What are the key responsibilities of a Production Clerk?

The key responsibilities of a Production Clerk include managing inventory, production planning, quality control, order processing, data entry, material handling, and collaborating with various teams to ensure efficient production processes.

What qualifications are required to become a Production Clerk?

A Production Clerk typically requires a high school diploma or equivalent qualification. Some employers may prefer candidates with a degree or diploma in supply chain management, logistics, or a related field. Additionally, experience in inventory management, production planning, or quality control is highly valued.

What skills are essential for a Production Clerk?

Essential skills for a Production Clerk include inventory management, production planning, quality control, order processing, data entry, material handling, and strong communication and interpersonal skills.

What is the career path for a Production Clerk?

A Production Clerk can advance their career by gaining experience and developing their skills in inventory management, production planning, and quality control. With additional experience and education, they can move into supervisory roles, such as Production Supervisor or Inventory Manager.

What is the average salary for a Production Clerk?

The average salary for a Production Clerk varies depending on experience, location, and company size. According to Indeed, the average salary for a Production Clerk in the United States is around $37,000 per year.

What are the job prospects for Production Clerks?

The job outlook for Production Clerks is expected to be stable in the coming years due to the increasing demand for efficient inventory management and production planning in various industries.

What are the challenges faced by Production Clerks?

Production Clerks may face challenges related to managing large volumes of inventory, ensuring accurate data entry, meeting production deadlines, and resolving discrepancies with suppliers or production teams.