Are you a seasoned Operations and Maintenance Technician seeking a new career path? Discover our professionally built Operations and Maintenance Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

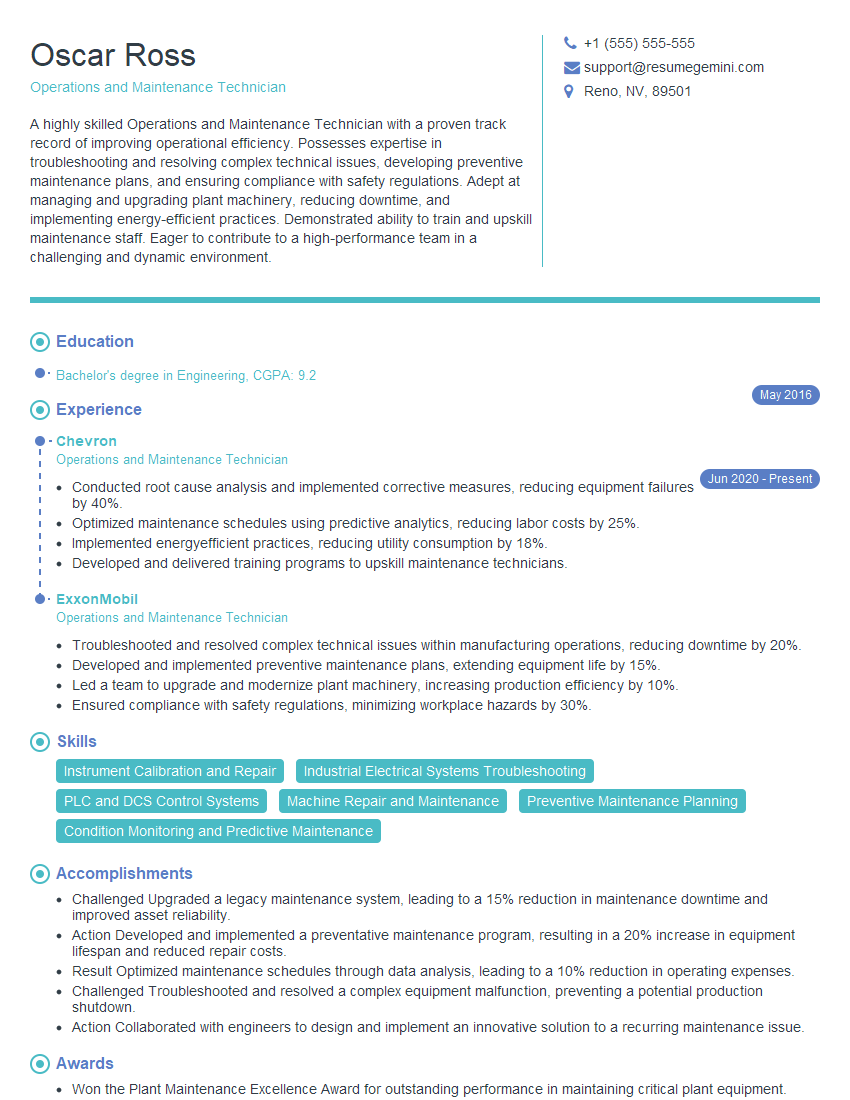

Oscar Ross

Operations and Maintenance Technician

Summary

A highly skilled Operations and Maintenance Technician with a proven track record of improving operational efficiency. Possesses expertise in troubleshooting and resolving complex technical issues, developing preventive maintenance plans, and ensuring compliance with safety regulations. Adept at managing and upgrading plant machinery, reducing downtime, and implementing energy-efficient practices. Demonstrated ability to train and upskill maintenance staff. Eager to contribute to a high-performance team in a challenging and dynamic environment.

Education

Bachelor’s degree in Engineering

May 2016

Skills

- Instrument Calibration and Repair

- Industrial Electrical Systems Troubleshooting

- PLC and DCS Control Systems

- Machine Repair and Maintenance

- Preventive Maintenance Planning

- Condition Monitoring and Predictive Maintenance

Work Experience

Operations and Maintenance Technician

- Conducted root cause analysis and implemented corrective measures, reducing equipment failures by 40%.

- Optimized maintenance schedules using predictive analytics, reducing labor costs by 25%.

- Implemented energyefficient practices, reducing utility consumption by 18%.

- Developed and delivered training programs to upskill maintenance technicians.

Operations and Maintenance Technician

- Troubleshooted and resolved complex technical issues within manufacturing operations, reducing downtime by 20%.

- Developed and implemented preventive maintenance plans, extending equipment life by 15%.

- Led a team to upgrade and modernize plant machinery, increasing production efficiency by 10%.

- Ensured compliance with safety regulations, minimizing workplace hazards by 30%.

Accomplishments

- Challenged Upgraded a legacy maintenance system, leading to a 15% reduction in maintenance downtime and improved asset reliability.

- Action Developed and implemented a preventative maintenance program, resulting in a 20% increase in equipment lifespan and reduced repair costs.

- Result Optimized maintenance schedules through data analysis, leading to a 10% reduction in operating expenses.

- Challenged Troubleshooted and resolved a complex equipment malfunction, preventing a potential production shutdown.

- Action Collaborated with engineers to design and implement an innovative solution to a recurring maintenance issue.

Awards

- Won the Plant Maintenance Excellence Award for outstanding performance in maintaining critical plant equipment.

- Recognized with the Maintenance Technician of the Year Award for exceptional troubleshooting and repair skills.

- Received the Safety Star Award for maintaining an exemplary safety record and fostering a safe work environment.

- Maintenance Excellence Award for consistently exceeding maintenance objectives and achieving exceptional results.

Certificates

- Certified Maintenance and Reliability Technician (CMRT)

- Certified Maintenance Manager (CMM)

- Certified Reliability Engineer (CRE)

- Certified Asset Management Professional (CAMP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Operations and Maintenance Technician

- Showcase your technical expertise and problem-solving abilities by quantifying your accomplishments and providing specific examples.

- Highlight your experience in implementing preventive maintenance plans and reducing equipment failures, demonstrating your commitment to maximizing equipment uptime.

- Emphasize your proficiency in using predictive analytics and advanced technologies to optimize maintenance schedules and minimize labor costs.

- Include keywords related to the job title and responsibilities to improve your resume’s visibility in job searches.

- Proofread your resume carefully to ensure accuracy and clarity, as errors can detract from your professional image.

Essential Experience Highlights for a Strong Operations and Maintenance Technician Resume

- Troubleshoot and resolve complex technical issues to minimize downtime and ensure smooth plant operations.

- Develop and implement preventive maintenance plans to extend equipment life and optimize equipment performance.

- Collaborate with engineers and maintenance personnel to manage and upgrade plant machinery, automating processes, and increasing production efficiency.

- Conduct root cause analysis, implement corrective measures, and drive continuous improvement initiatives to reduce equipment failures and enhance maintenance effectiveness.

- Optimize maintenance schedules using predictive analytics and advanced technologies to improve maintenance efficiency and reduce labor costs.

- Implement energy-efficient practices to reduce utility consumption, promote sustainability, and lower operating costs.

- Lead and mentor maintenance technicians, providing training and development opportunities to enhance their skills and knowledge.

Frequently Asked Questions (FAQ’s) For Operations and Maintenance Technician

What is the primary role of an Operations and Maintenance Technician?

An Operations and Maintenance Technician is responsible for maintaining and troubleshooting plant equipment to ensure optimal performance, minimize downtime, and maximize production efficiency.

What are the essential skills required for this role?

Effective Operations and Maintenance Technicians possess expertise in instrument calibration, electrical troubleshooting, PLC/DCS control systems, machine repair, preventive maintenance planning, and condition monitoring.

How can I improve my chances of getting hired as an Operations and Maintenance Technician?

To increase your competitiveness, consider pursuing a degree in engineering, obtaining industry certifications, and gaining hands-on experience through internships or apprenticeships.

What are the career advancement opportunities for Operations and Maintenance Technicians?

With experience and additional training, Operations and Maintenance Technicians can advance to roles such as Maintenance Supervisor, Plant Engineer, or Maintenance Manager.

How can I stay updated on the latest industry trends and technologies in this field?

Attend industry conferences, read technical journals and articles, and participate in online forums and webinars to stay abreast of advancements in operations and maintenance practices.

What are the key responsibilities of an Operations and Maintenance Technician in a manufacturing environment?

In a manufacturing setting, Operations and Maintenance Technicians are responsible for ensuring the smooth operation and maintenance of machinery and equipment within production lines, minimizing downtime and maximizing production efficiency.