Are you a seasoned Inserting Machine Operator seeking a new career path? Discover our professionally built Inserting Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

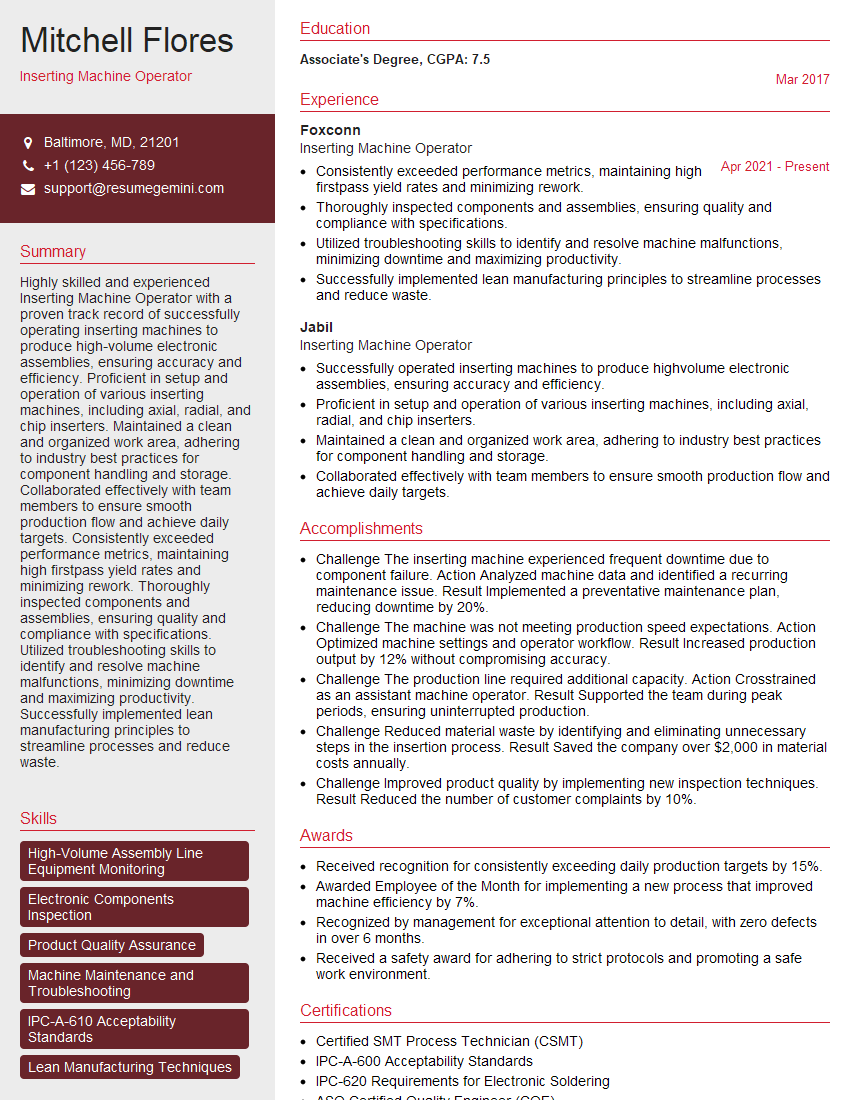

Mitchell Flores

Inserting Machine Operator

Summary

Highly skilled and experienced Inserting Machine Operator with a proven track record of successfully operating inserting machines to produce high-volume electronic assemblies, ensuring accuracy and efficiency. Proficient in setup and operation of various inserting machines, including axial, radial, and chip inserters. Maintained a clean and organized work area, adhering to industry best practices for component handling and storage. Collaborated effectively with team members to ensure smooth production flow and achieve daily targets. Consistently exceeded performance metrics, maintaining high firstpass yield rates and minimizing rework. Thoroughly inspected components and assemblies, ensuring quality and compliance with specifications. Utilized troubleshooting skills to identify and resolve machine malfunctions, minimizing downtime and maximizing productivity. Successfully implemented lean manufacturing principles to streamline processes and reduce waste.

Education

Associate’s Degree

March 2017

Skills

- High-Volume Assembly Line Equipment Monitoring

- Electronic Components Inspection

- Product Quality Assurance

- Machine Maintenance and Troubleshooting

- IPC-A-610 Acceptability Standards

- Lean Manufacturing Techniques

Work Experience

Inserting Machine Operator

- Consistently exceeded performance metrics, maintaining high firstpass yield rates and minimizing rework.

- Thoroughly inspected components and assemblies, ensuring quality and compliance with specifications.

- Utilized troubleshooting skills to identify and resolve machine malfunctions, minimizing downtime and maximizing productivity.

- Successfully implemented lean manufacturing principles to streamline processes and reduce waste.

Inserting Machine Operator

- Successfully operated inserting machines to produce highvolume electronic assemblies, ensuring accuracy and efficiency.

- Proficient in setup and operation of various inserting machines, including axial, radial, and chip inserters.

- Maintained a clean and organized work area, adhering to industry best practices for component handling and storage.

- Collaborated effectively with team members to ensure smooth production flow and achieve daily targets.

Accomplishments

- Challenge The inserting machine experienced frequent downtime due to component failure. Action Analyzed machine data and identified a recurring maintenance issue. Result Implemented a preventative maintenance plan, reducing downtime by 20%.

- Challenge The machine was not meeting production speed expectations. Action Optimized machine settings and operator workflow. Result Increased production output by 12% without compromising accuracy.

- Challenge The production line required additional capacity. Action Crosstrained as an assistant machine operator. Result Supported the team during peak periods, ensuring uninterrupted production.

- Challenge Reduced material waste by identifying and eliminating unnecessary steps in the insertion process. Result Saved the company over $2,000 in material costs annually.

- Challenge Improved product quality by implementing new inspection techniques. Result Reduced the number of customer complaints by 10%.

Awards

- Received recognition for consistently exceeding daily production targets by 15%.

- Awarded Employee of the Month for implementing a new process that improved machine efficiency by 7%.

- Recognized by management for exceptional attention to detail, with zero defects in over 6 months.

- Received a safety award for adhering to strict protocols and promoting a safe work environment.

Certificates

- Certified SMT Process Technician (CSMT)

- IPC-A-600 Acceptability Standards

- IPC-620 Requirements for Electronic Soldering

- ASQ Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Inserting Machine Operator

- Highlight your experience in operating inserting machines and your ability to produce high-volume electronic assemblies.

- Emphasize your proficiency in setting up and operating various inserting machines, including axial, radial, and chip inserters.

- Showcase your ability to maintain a clean and organized work area, as well as your adherence to industry best practices for component handling and storage.

- Demonstrate your ability to collaborate with team members and work effectively in a fast-paced environment.

- Highlight your inspection skills and your ability to ensure the quality of components and assemblies.

Essential Experience Highlights for a Strong Inserting Machine Operator Resume

- Operate inserting machines to produce high-volume electronic assemblies.

- Set up and operate various inserting machines, including axial, radial, and chip inserters.

- Maintain a clean and organized work area, adhering to industry best practices for component handling and storage.

- Collaborate with team members to ensure smooth production flow and achieve daily targets.

- Inspect components and assemblies, ensuring quality and compliance with specifications.

- Troubleshoot and resolve machine malfunctions, minimizing downtime and maximizing productivity.

- Implement lean manufacturing principles to streamline processes and reduce waste.

Frequently Asked Questions (FAQ’s) For Inserting Machine Operator

What are the key skills required to be an Inserting Machine Operator?

The key skills required to be an Inserting Machine Operator include: High-Volume Assembly Line Equipment Monitoring, Electronic Components Inspection, Product Quality Assurance, Machine Maintenance and Troubleshooting, IPC-A-610 Acceptability Standards, and Lean Manufacturing Techniques.

What are the job responsibilities of an Inserting Machine Operator?

The job responsibilities of an Inserting Machine Operator include: Operating inserting machines to produce high-volume electronic assemblies, Setting up and operating various inserting machines, Maintaining a clean and organized work area, Collaborating with team members to ensure smooth production flow and achieve daily targets, Inspecting components and assemblies, ensuring quality and compliance with specifications, Troubleshooting and resolving machine malfunctions, and Implementing lean manufacturing principles to streamline processes and reduce waste.

What are the career prospects for an Inserting Machine Operator?

Inserting Machine Operators can advance their careers by becoming supervisors or managers in the manufacturing industry. They can also specialize in a particular type of inserting machine or electronic assembly, or they can move into other areas of the electronics industry, such as design or engineering.

What is the work environment of an Inserting Machine Operator like?

Inserting Machine Operators typically work in a manufacturing environment, which can be noisy and fast-paced. They may be required to work overtime or on weekends to meet production deadlines.

What are the educational requirements for an Inserting Machine Operator?

Most Inserting Machine Operators have a high school diploma or equivalent. Some employers may require a Associate’s Degree in a related field, such as electronics or manufacturing.

What are the salary expectations for an Inserting Machine Operator?

The salary expectations for an Inserting Machine Operator will vary depending on their experience, skills, and location. According to Indeed, the average salary for an Inserting Machine Operator in the United States is $19.50 per hour.

What are the benefits of being an Inserting Machine Operator?

The benefits of being an Inserting Machine Operator include: Job security, as the demand for electronic assemblies is expected to continue to grow, Opportunities for advancement, as Inserting Machine Operators can move into supervisory or management positions, Competitive salary and benefits, and the satisfaction of working in a fast-paced and challenging environment.