Are you a seasoned Dipper seeking a new career path? Discover our professionally built Dipper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

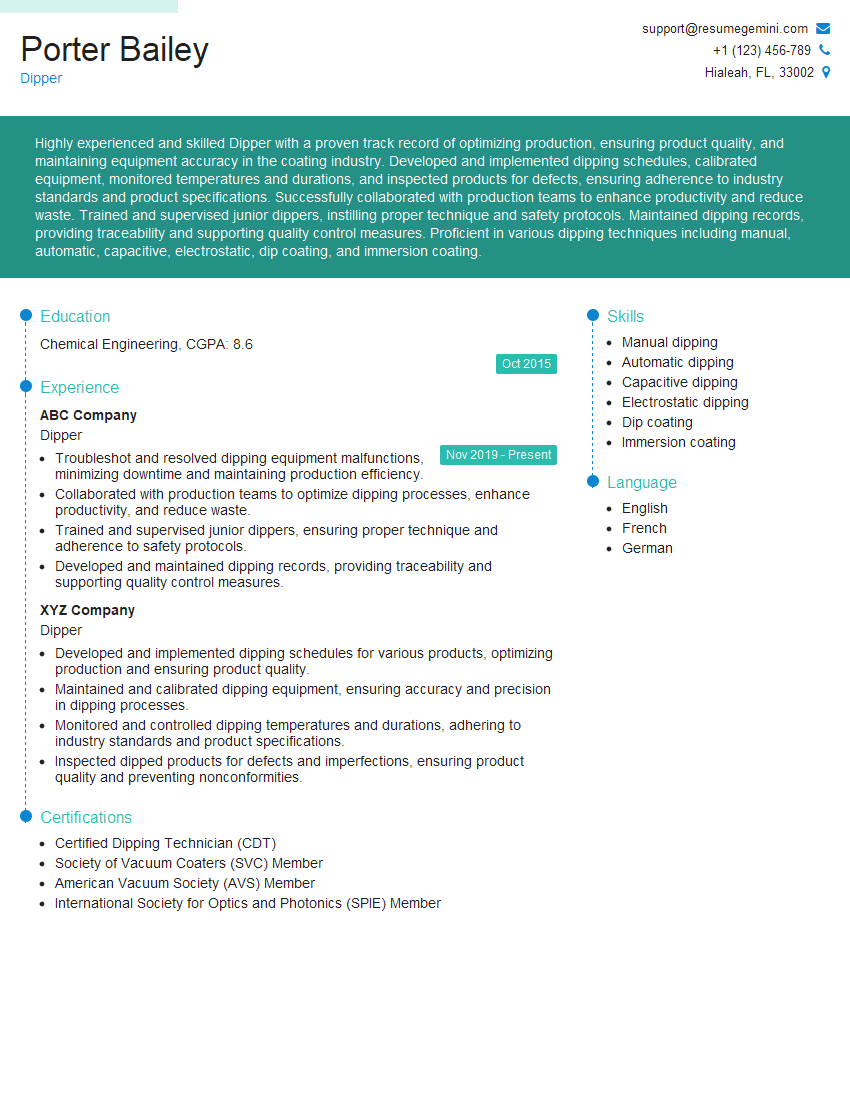

Porter Bailey

Dipper

Summary

Highly experienced and skilled Dipper with a proven track record of optimizing production, ensuring product quality, and maintaining equipment accuracy in the coating industry. Developed and implemented dipping schedules, calibrated equipment, monitored temperatures and durations, and inspected products for defects, ensuring adherence to industry standards and product specifications. Successfully collaborated with production teams to enhance productivity and reduce waste. Trained and supervised junior dippers, instilling proper technique and safety protocols. Maintained dipping records, providing traceability and supporting quality control measures. Proficient in various dipping techniques including manual, automatic, capacitive, electrostatic, dip coating, and immersion coating.

Education

Chemical Engineering

October 2015

Skills

- Manual dipping

- Automatic dipping

- Capacitive dipping

- Electrostatic dipping

- Dip coating

- Immersion coating

Work Experience

Dipper

- Troubleshot and resolved dipping equipment malfunctions, minimizing downtime and maintaining production efficiency.

- Collaborated with production teams to optimize dipping processes, enhance productivity, and reduce waste.

- Trained and supervised junior dippers, ensuring proper technique and adherence to safety protocols.

- Developed and maintained dipping records, providing traceability and supporting quality control measures.

Dipper

- Developed and implemented dipping schedules for various products, optimizing production and ensuring product quality.

- Maintained and calibrated dipping equipment, ensuring accuracy and precision in dipping processes.

- Monitored and controlled dipping temperatures and durations, adhering to industry standards and product specifications.

- Inspected dipped products for defects and imperfections, ensuring product quality and preventing nonconformities.

Certificates

- Certified Dipping Technician (CDT)

- Society of Vacuum Coaters (SVC) Member

- American Vacuum Society (AVS) Member

- International Society for Optics and Photonics (SPIE) Member

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Dipper

- Highlight your expertise in various dipping techniques, including manual, automatic, capacitive, electrostatic, dip coating, and immersion coating.

- Quantify your accomplishments with specific metrics, such as the percentage of production increase achieved or the reduction in waste.

- Demonstrate your ability to maintain and calibrate dipping equipment, ensuring accuracy and precision.

- Showcase your experience in troubleshooting and resolving dipping equipment malfunctions, minimizing downtime and maintaining production efficiency.

- Emphasize your attention to detail and commitment to product quality, ensuring that dipped products meet industry standards and customer specifications.

Essential Experience Highlights for a Strong Dipper Resume

- Developed and implemented dipping schedules to optimize production and ensure product quality.

- Maintained and calibrated dipping equipment, ensuring accuracy and precision in dipping processes.

- Monitored and controlled dipping temperatures and durations, adhering to industry standards and product specifications.

- Inspected dipped products for defects and imperfections, ensuring product quality and preventing nonconformities.

- Troubleshot and resolved dipping equipment malfunctions, minimizing downtime and maintaining production efficiency.

- Collaborated with production teams to optimize dipping processes, enhance productivity, and reduce waste.

- Developed and maintained dipping records, providing traceability and supporting quality control measures.

Frequently Asked Questions (FAQ’s) For Dipper

What are the key responsibilities of a Dipper?

The key responsibilities of a Dipper include developing and implementing dipping schedules, maintaining and calibrating dipping equipment, monitoring and controlling dipping temperatures and durations, inspecting dipped products for defects, troubleshooting and resolving dipping equipment malfunctions, collaborating with production teams to optimize dipping processes, and developing and maintaining dipping records.

What are the essential skills required for a Dipper?

The essential skills required for a Dipper include manual dipping, automatic dipping, capacitive dipping, electrostatic dipping, dip coating, immersion coating, and a strong attention to detail and commitment to product quality.

What industries employ Dippers?

Dippers are employed in various industries, including manufacturing, automotive, aerospace, and electronics, where the application of protective or decorative coatings is required.

What is the career path for a Dipper?

Dippers can advance their careers by becoming Senior Dippers, Supervisors, or Quality Control Inspectors. With experience and additional training, they may also pursue management positions in the coating industry.

What is the salary range for a Dipper?

The salary range for a Dipper varies depending on experience, location, and industry. According to Salary.com, the average annual salary for a Dipper in the United States is around $45,000.

What are the challenges faced by Dippers?

Dippers may face challenges related to maintaining consistent product quality, meeting production targets, and working with hazardous materials. They must also stay up-to-date with advancements in dipping technologies and industry standards.