Are you a seasoned Sheet Metal Supervisor seeking a new career path? Discover our professionally built Sheet Metal Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

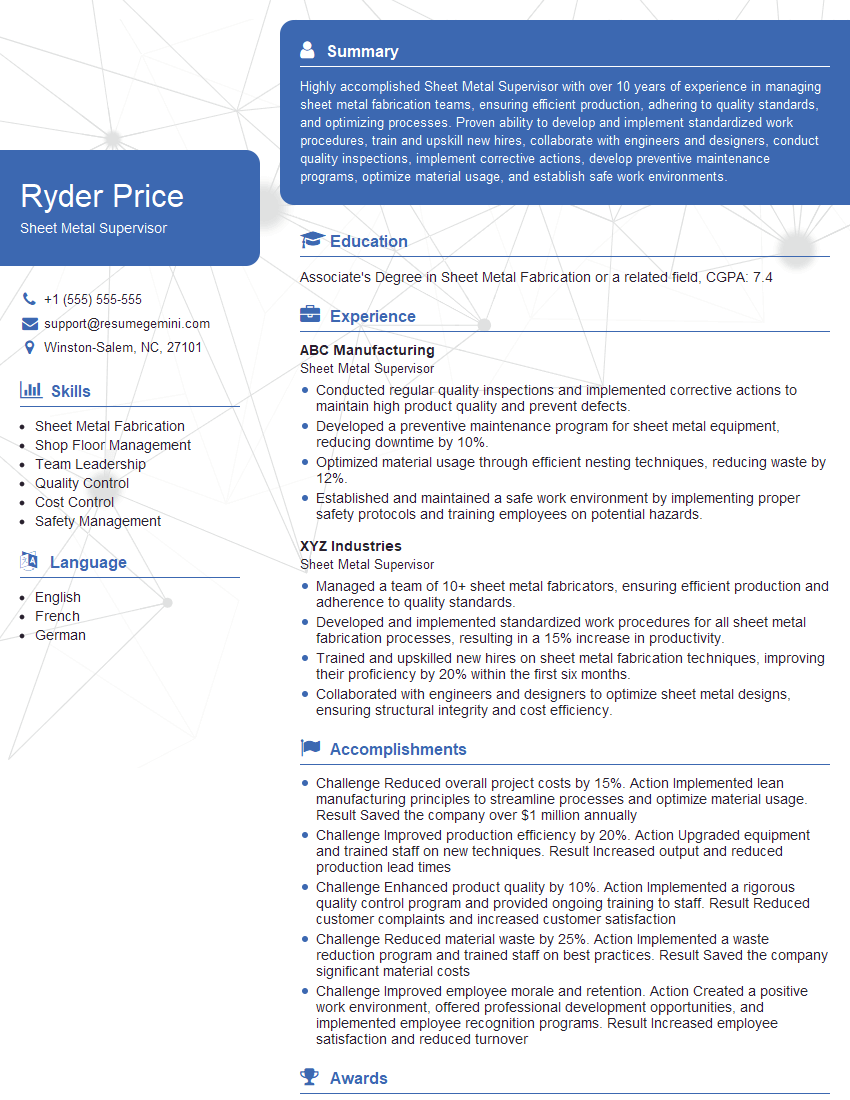

Ryder Price

Sheet Metal Supervisor

Summary

Highly accomplished Sheet Metal Supervisor with over 10 years of experience in managing sheet metal fabrication teams, ensuring efficient production, adhering to quality standards, and optimizing processes. Proven ability to develop and implement standardized work procedures, train and upskill new hires, collaborate with engineers and designers, conduct quality inspections, implement corrective actions, develop preventive maintenance programs, optimize material usage, and establish safe work environments.

Education

Associate’s Degree in Sheet Metal Fabrication or a related field

July 2017

Skills

- Sheet Metal Fabrication

- Shop Floor Management

- Team Leadership

- Quality Control

- Cost Control

- Safety Management

Work Experience

Sheet Metal Supervisor

- Conducted regular quality inspections and implemented corrective actions to maintain high product quality and prevent defects.

- Developed a preventive maintenance program for sheet metal equipment, reducing downtime by 10%.

- Optimized material usage through efficient nesting techniques, reducing waste by 12%.

- Established and maintained a safe work environment by implementing proper safety protocols and training employees on potential hazards.

Sheet Metal Supervisor

- Managed a team of 10+ sheet metal fabricators, ensuring efficient production and adherence to quality standards.

- Developed and implemented standardized work procedures for all sheet metal fabrication processes, resulting in a 15% increase in productivity.

- Trained and upskilled new hires on sheet metal fabrication techniques, improving their proficiency by 20% within the first six months.

- Collaborated with engineers and designers to optimize sheet metal designs, ensuring structural integrity and cost efficiency.

Accomplishments

- Challenge Reduced overall project costs by 15%. Action Implemented lean manufacturing principles to streamline processes and optimize material usage. Result Saved the company over $1 million annually

- Challenge Improved production efficiency by 20%. Action Upgraded equipment and trained staff on new techniques. Result Increased output and reduced production lead times

- Challenge Enhanced product quality by 10%. Action Implemented a rigorous quality control program and provided ongoing training to staff. Result Reduced customer complaints and increased customer satisfaction

- Challenge Reduced material waste by 25%. Action Implemented a waste reduction program and trained staff on best practices. Result Saved the company significant material costs

- Challenge Improved employee morale and retention. Action Created a positive work environment, offered professional development opportunities, and implemented employee recognition programs. Result Increased employee satisfaction and reduced turnover

Awards

- Received the Excellence in Sheet Metal Management award from the American Society of Sheet Metal and Air Conditioning Contractors

- Awarded Supervisor of the Year for consistently exceeding production targets and maintaining highquality standards

- Recognized with a Safety Excellence award for implementing innovative safety protocols that reduced workplace accidents by 25%

- Won the Innovation in Sheet Metal Fabrication award for developing a new process that increased productivity by 30%

Certificates

- OSHA 30-Hour Construction Safety

- ASME Boiler and Pressure Vessel Code

- National Institute for Metalworking Skills (NIMS)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Supervisor

- Highlight your experience in managing sheet metal fabrication teams and ensuring efficient production.

- Quantify your accomplishments with specific metrics, such as increased productivity and reduced waste.

- Showcase your ability to develop and implement standardized work procedures.

- Emphasize your skills in training and upskilling new hires.

- Demonstrate your knowledge of quality control and safety management.

Essential Experience Highlights for a Strong Sheet Metal Supervisor Resume

- Managed a team of 10+ sheet metal fabricators, ensuring efficient production and adherence to quality standards.

- Developed and implemented standardized work procedures for all sheet metal fabrication processes, resulting in a 15% increase in productivity.

- Trained and upskilled new hires on sheet metal fabrication techniques, improving their proficiency by 20% within the first six months.

- Collaborated with engineers and designers to optimize sheet metal designs, ensuring structural integrity and cost efficiency.

- Conducted regular quality inspections and implemented corrective actions to maintain high product quality and prevent defects.

- Developed a preventive maintenance program for sheet metal equipment, reducing downtime by 10%.

- Optimized material usage through efficient nesting techniques, reducing waste by 12%.

Frequently Asked Questions (FAQ’s) For Sheet Metal Supervisor

What are the key responsibilities of a Sheet Metal Supervisor?

Key responsibilities include managing sheet metal fabrication teams, developing standardized work procedures, training new hires, collaborating with engineers and designers, conducting quality inspections, implementing corrective actions, and optimizing material usage.

What qualifications are required to become a Sheet Metal Supervisor?

Typically, an Associate’s Degree in Sheet Metal Fabrication or a related field is required, along with several years of experience in sheet metal fabrication.

What are the career prospects for Sheet Metal Supervisors?

Sheet Metal Supervisors can advance to management positions, such as Production Manager or Plant Manager. They may also specialize in areas such as quality control or safety management.

What are the challenges faced by Sheet Metal Supervisors?

Challenges include managing production schedules, ensuring quality standards, and motivating and training employees. They may also face challenges related to material costs and equipment maintenance.

What skills are essential for Sheet Metal Supervisors?

Essential skills include knowledge of sheet metal fabrication techniques, project management, quality control, safety management, and communication.

What is the work environment like for Sheet Metal Supervisors?

Sheet Metal Supervisors typically work in manufacturing facilities, where they may be exposed to noise, dust, and fumes. They may also work overtime or on weekends to meet production deadlines.