Are you a seasoned Cupola Liner seeking a new career path? Discover our professionally built Cupola Liner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

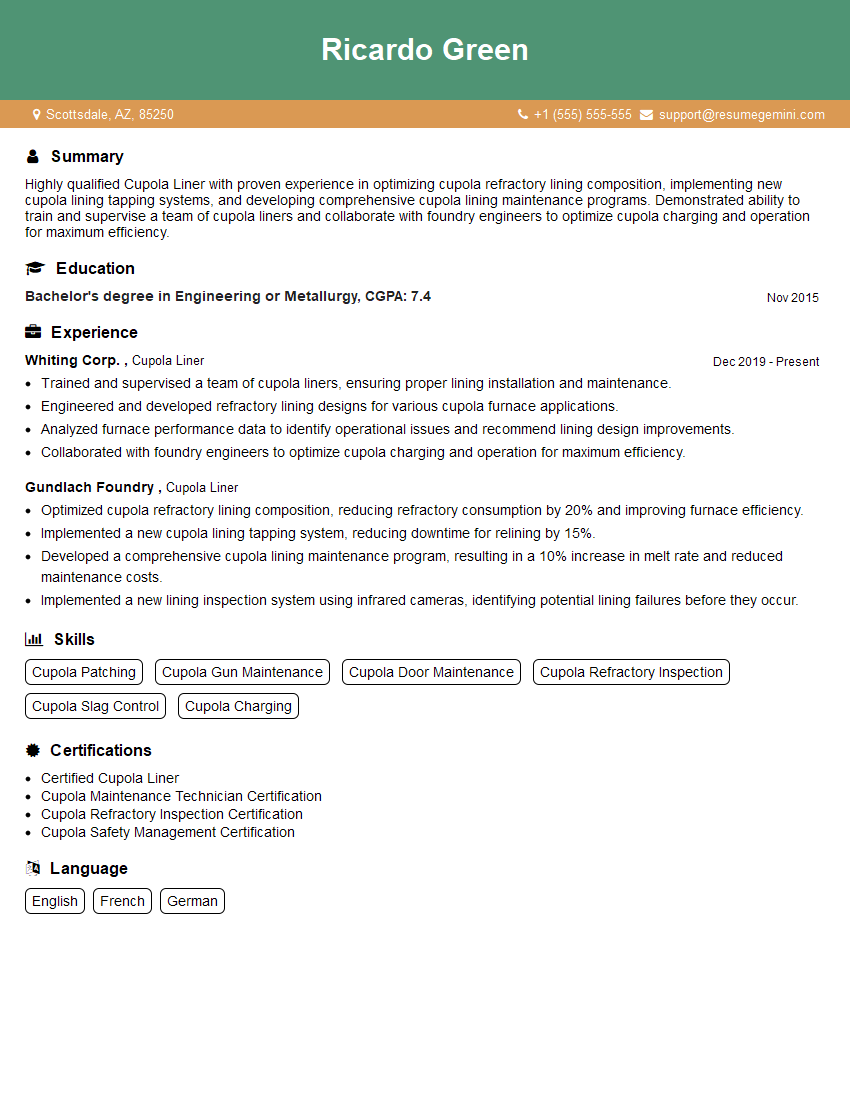

Ricardo Green

Cupola Liner

Summary

Highly qualified Cupola Liner with proven experience in optimizing cupola refractory lining composition, implementing new cupola lining tapping systems, and developing comprehensive cupola lining maintenance programs. Demonstrated ability to train and supervise a team of cupola liners and collaborate with foundry engineers to optimize cupola charging and operation for maximum efficiency.

Education

Bachelor’s degree in Engineering or Metallurgy

November 2015

Skills

- Cupola Patching

- Cupola Gun Maintenance

- Cupola Door Maintenance

- Cupola Refractory Inspection

- Cupola Slag Control

- Cupola Charging

Work Experience

Cupola Liner

- Trained and supervised a team of cupola liners, ensuring proper lining installation and maintenance.

- Engineered and developed refractory lining designs for various cupola furnace applications.

- Analyzed furnace performance data to identify operational issues and recommend lining design improvements.

- Collaborated with foundry engineers to optimize cupola charging and operation for maximum efficiency.

Cupola Liner

- Optimized cupola refractory lining composition, reducing refractory consumption by 20% and improving furnace efficiency.

- Implemented a new cupola lining tapping system, reducing downtime for relining by 15%.

- Developed a comprehensive cupola lining maintenance program, resulting in a 10% increase in melt rate and reduced maintenance costs.

- Implemented a new lining inspection system using infrared cameras, identifying potential lining failures before they occur.

Certificates

- Certified Cupola Liner

- Cupola Maintenance Technician Certification

- Cupola Refractory Inspection Certification

- Cupola Safety Management Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cupola Liner

- Quantify your accomplishments with specific metrics, such as percentages or dollar amounts.

- Highlight your experience in optimizing cupola performance and reducing operating costs.

- Demonstrate your ability to lead and manage a team.

- Stay up-to-date on the latest cupola lining technologies and best practices.

- Consider obtaining relevant certifications, such as the Certified Cupola Operator (CCO) certification.

Essential Experience Highlights for a Strong Cupola Liner Resume

- Optimize cupola refractory lining composition to reduce refractory consumption and improve furnace efficiency.

- Implement new cupola lining tapping systems to reduce downtime for relining.

- Develop and implement comprehensive cupola lining maintenance programs to increase melt rate and reduce maintenance costs.

- Implement new lining inspection systems using infrared cameras to identify potential lining failures before they occur.

- Train and supervise a team of cupola liners to ensure proper lining installation and maintenance.

- Engineer and develop refractory lining designs for various cupola furnace applications.

- Analyze furnace performance data to identify operational issues and recommend lining design improvements.

Frequently Asked Questions (FAQ’s) For Cupola Liner

What are the key skills required for a Cupola Liner?

Key skills for a Cupola Liner include cupola patching, cupola gun maintenance, cupola door maintenance, cupola refractory inspection, cupola slag control, and cupola charging.

What are the educational requirements for a Cupola Liner?

A Cupola Liner typically requires a high school diploma or equivalent qualification, along with on-the-job training and experience.

What is the average salary for a Cupola Liner?

The average salary for a Cupola Liner can vary depending on factors such as experience, location, and company size, but typically ranges between $40,000 and $60,000 per year.

What are the career opportunities for a Cupola Liner?

Career opportunities for a Cupola Liner can include advancement to supervisory or management roles, or specialization in areas such as refractory engineering or furnace optimization.

What are the working conditions like for a Cupola Liner?

Cupola Liners typically work in industrial environments, which can involve exposure to heat, noise, and dust.

What are the safety precautions that should be taken by a Cupola Liner?

Important safety precautions for a Cupola Liner include wearing appropriate personal protective equipment (PPE), following established safety protocols, and being aware of potential hazards.

What are the benefits of working as a Cupola Liner?

Benefits of working as a Cupola Liner can include job stability, opportunities for skill development, and the satisfaction of contributing to the production process.