Are you a seasoned Molder seeking a new career path? Discover our professionally built Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

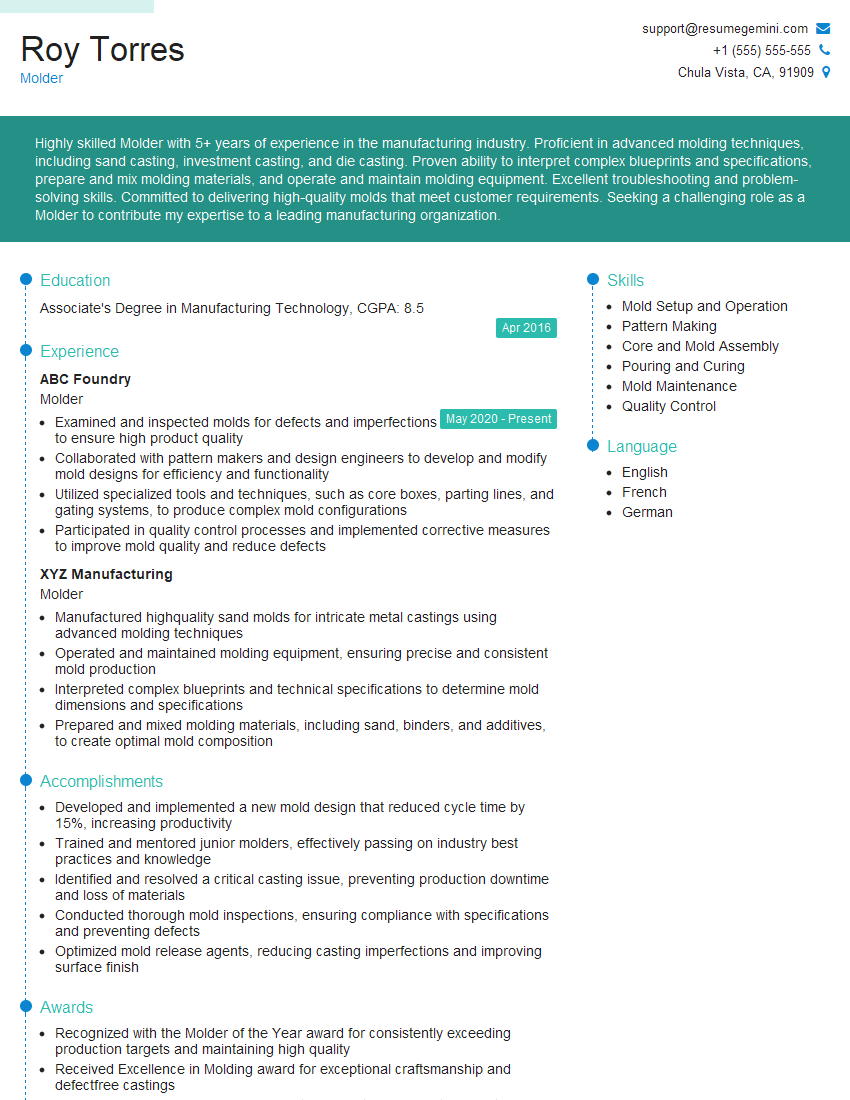

Roy Torres

Molder

Summary

Highly skilled Molder with 5+ years of experience in the manufacturing industry. Proficient in advanced molding techniques, including sand casting, investment casting, and die casting. Proven ability to interpret complex blueprints and specifications, prepare and mix molding materials, and operate and maintain molding equipment. Excellent troubleshooting and problem-solving skills. Committed to delivering high-quality molds that meet customer requirements. Seeking a challenging role as a Molder to contribute my expertise to a leading manufacturing organization.

Education

Associate’s Degree in Manufacturing Technology

April 2016

Skills

- Mold Setup and Operation

- Pattern Making

- Core and Mold Assembly

- Pouring and Curing

- Mold Maintenance

- Quality Control

Work Experience

Molder

- Examined and inspected molds for defects and imperfections to ensure high product quality

- Collaborated with pattern makers and design engineers to develop and modify mold designs for efficiency and functionality

- Utilized specialized tools and techniques, such as core boxes, parting lines, and gating systems, to produce complex mold configurations

- Participated in quality control processes and implemented corrective measures to improve mold quality and reduce defects

Molder

- Manufactured highquality sand molds for intricate metal castings using advanced molding techniques

- Operated and maintained molding equipment, ensuring precise and consistent mold production

- Interpreted complex blueprints and technical specifications to determine mold dimensions and specifications

- Prepared and mixed molding materials, including sand, binders, and additives, to create optimal mold composition

Accomplishments

- Developed and implemented a new mold design that reduced cycle time by 15%, increasing productivity

- Trained and mentored junior molders, effectively passing on industry best practices and knowledge

- Identified and resolved a critical casting issue, preventing production downtime and loss of materials

- Conducted thorough mold inspections, ensuring compliance with specifications and preventing defects

- Optimized mold release agents, reducing casting imperfections and improving surface finish

Awards

- Recognized with the Molder of the Year award for consistently exceeding production targets and maintaining high quality

- Received Excellence in Molding award for exceptional craftsmanship and defectfree castings

- Commended for superior mold preparation, resulting in defectfree castings and minimizing rework

- Recognized with Safety Star award for maintaining a safe and hazardfree work environment

Certificates

- Certified Molder Technician

- Composite Manufacturing Technician

- Society of Plastics Engineers (SPE) Certification

- American Society of Composites (ASC) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Molder

- Highlight your technical skills and experience in advanced molding techniques, such as sand casting, investment casting, and die casting.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the manufacturing process.

- Showcase your ability to interpret complex blueprints and specifications, as well as your knowledge of molding materials and equipment.

- Emphasize your problem-solving and troubleshooting skills, as molders often need to identify and resolve issues during the production process.

- Highlight your commitment to quality and safety, as molders are responsible for ensuring that molds meet customer requirements and industry standards.

Essential Experience Highlights for a Strong Molder Resume

- Manufactured high-quality sand molds for intricate metal castings using advanced molding techniques.

- Operated and maintained molding equipment, ensuring precise and consistent mold production.

- Interpreted complex blueprints and technical specifications to determine mold dimensions and specifications.

- Prepared and mixed molding materials, including sand, binders, and additives, to create optimal mold composition.

- Examined and inspected molds for defects and imperfections to ensure high product quality.

- Collaborated with pattern makers and design engineers to develop and modify mold designs for efficiency and functionality.

- Utilized specialized tools and techniques, such as core boxes, parting lines, and gating systems, to produce complex mold configurations.

Frequently Asked Questions (FAQ’s) For Molder

What are the key skills required for a Molder?

The key skills required for a Molder include advanced molding techniques, blueprint reading, material preparation, equipment operation, quality control, and troubleshooting.

What is the work environment of a Molder like?

Molders typically work in foundries or manufacturing facilities, where they are exposed to noise, dust, and potential hazards. They may also work in hot and humid conditions.

What are the career prospects for a Molder?

Molders with experience and expertise can advance to supervisory or management positions, such as Production Manager or Quality Control Manager. They may also specialize in specific molding techniques or materials.

What are the educational requirements for a Molder?

While formal education is not always required, most Molders have a high school diploma or equivalent. Some Molders may pursue an Associate’s Degree in Manufacturing Technology or a related field to enhance their skills and knowledge.

What are the typical job duties of a Molder?

Molders are responsible for creating molds used in the casting process. They interpret blueprints, prepare molding materials, operate molding equipment, and inspect molds for defects. They also collaborate with other departments to ensure that molds meet customer requirements.

What safety precautions should Molders take?

Molders should wear appropriate safety gear, including gloves, eye protection, and respirators. They should also be aware of the potential hazards associated with their work environment, such as hot metal, sharp tools, and heavy machinery.