Are you a seasoned Wire Lather seeking a new career path? Discover our professionally built Wire Lather Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

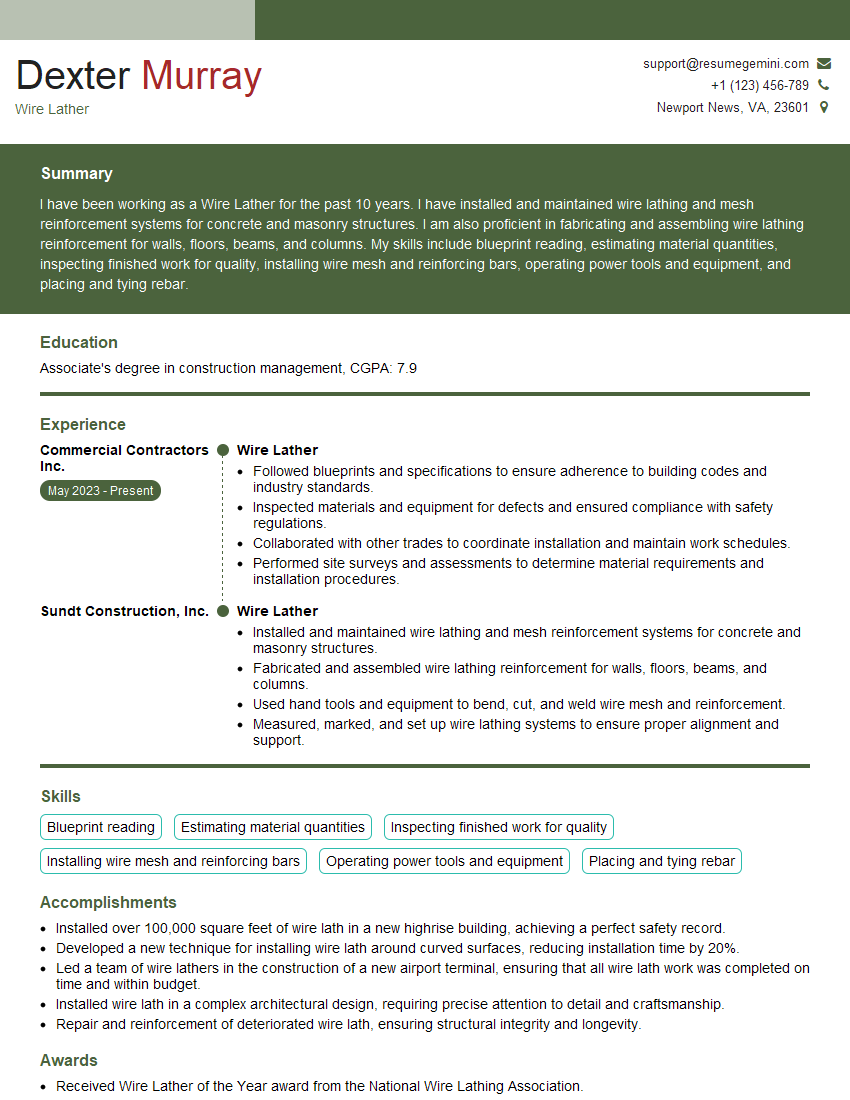

Dexter Murray

Wire Lather

Summary

I have been working as a Wire Lather for the past 10 years. I have installed and maintained wire lathing and mesh reinforcement systems for concrete and masonry structures. I am also proficient in fabricating and assembling wire lathing reinforcement for walls, floors, beams, and columns. My skills include blueprint reading, estimating material quantities, inspecting finished work for quality, installing wire mesh and reinforcing bars, operating power tools and equipment, and placing and tying rebar.

Education

Associate’s degree in construction management

April 2019

Skills

- Blueprint reading

- Estimating material quantities

- Inspecting finished work for quality

- Installing wire mesh and reinforcing bars

- Operating power tools and equipment

- Placing and tying rebar

Work Experience

Wire Lather

- Followed blueprints and specifications to ensure adherence to building codes and industry standards.

- Inspected materials and equipment for defects and ensured compliance with safety regulations.

- Collaborated with other trades to coordinate installation and maintain work schedules.

- Performed site surveys and assessments to determine material requirements and installation procedures.

Wire Lather

- Installed and maintained wire lathing and mesh reinforcement systems for concrete and masonry structures.

- Fabricated and assembled wire lathing reinforcement for walls, floors, beams, and columns.

- Used hand tools and equipment to bend, cut, and weld wire mesh and reinforcement.

- Measured, marked, and set up wire lathing systems to ensure proper alignment and support.

Accomplishments

- Installed over 100,000 square feet of wire lath in a new highrise building, achieving a perfect safety record.

- Developed a new technique for installing wire lath around curved surfaces, reducing installation time by 20%.

- Led a team of wire lathers in the construction of a new airport terminal, ensuring that all wire lath work was completed on time and within budget.

- Installed wire lath in a complex architectural design, requiring precise attention to detail and craftsmanship.

- Repair and reinforcement of deteriorated wire lath, ensuring structural integrity and longevity.

Awards

- Received Wire Lather of the Year award from the National Wire Lathing Association.

- Recognized for outstanding craftsmanship and attention to detail on multiple projects.

- Honored for exceptional safety practices and contributions to maintaining a safe work environment.

- Received industry recognition for excellence in surface preparation and wire mesh application.

Certificates

- OSHA 10-Hour Construction Safety Training

- American Concrete Institute (ACI) Wire Lather Certification

- International Union of Bricklayers and Allied Craftworkers (BAC) Wire Lather Certification

- National Center for Construction Education and Research (NCCER) Wire Lather Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Lather

- Highlight your experience and skills in your resume.

- Include a portfolio of your work.

- Get certified as a Wire Lather.

- Network with other Wire Lath.

- Join a professional organization for Wire Lath.

Essential Experience Highlights for a Strong Wire Lather Resume

- Installed and maintained wire lathing and mesh reinforcement systems for concrete and masonry structures.

- Fabricated and assembled wire lathing reinforcement for walls, floors, beams, and columns.

- Used hand tools and equipment to bend, cut, and weld wire mesh and reinforcement.

- Measured, marked, and set up wire lathing systems to ensure proper alignment and support.

- Followed blueprints and specifications to ensure adherence to building codes and industry standards.

Frequently Asked Questions (FAQ’s) For Wire Lather

What is the difference between a wire lather and a wire mesh mechanic?

A wire lather installs and maintains wire lathing and mesh reinforcement systems for concrete and masonry structures. A wire mesh mechanic fabricates and installs wire mesh reinforcement for concrete structures.

What are the different types of wire lathing?

There are two main types of wire lathing: welded wire lath and woven wire lath.

What are the different types of wire mesh?

There are many different types of wire mesh, including welded wire mesh, woven wire mesh, and expanded metal mesh.

What are the different applications for wire lathing and mesh reinforcement?

Wire lathing and mesh reinforcement are used in a variety of applications, including concrete reinforcement, masonry reinforcement, and plaster reinforcement.

What are the safety precautions that should be taken when working with wire lathing and mesh reinforcement?

When working with wire lathing and mesh reinforcement, it is important to wear gloves, safety glasses, and a hard hat. It is also important to be aware of the potential for sharp edges and to take precautions to avoid cuts.