Are you a seasoned Journeyman Sheet Metal Worker seeking a new career path? Discover our professionally built Journeyman Sheet Metal Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

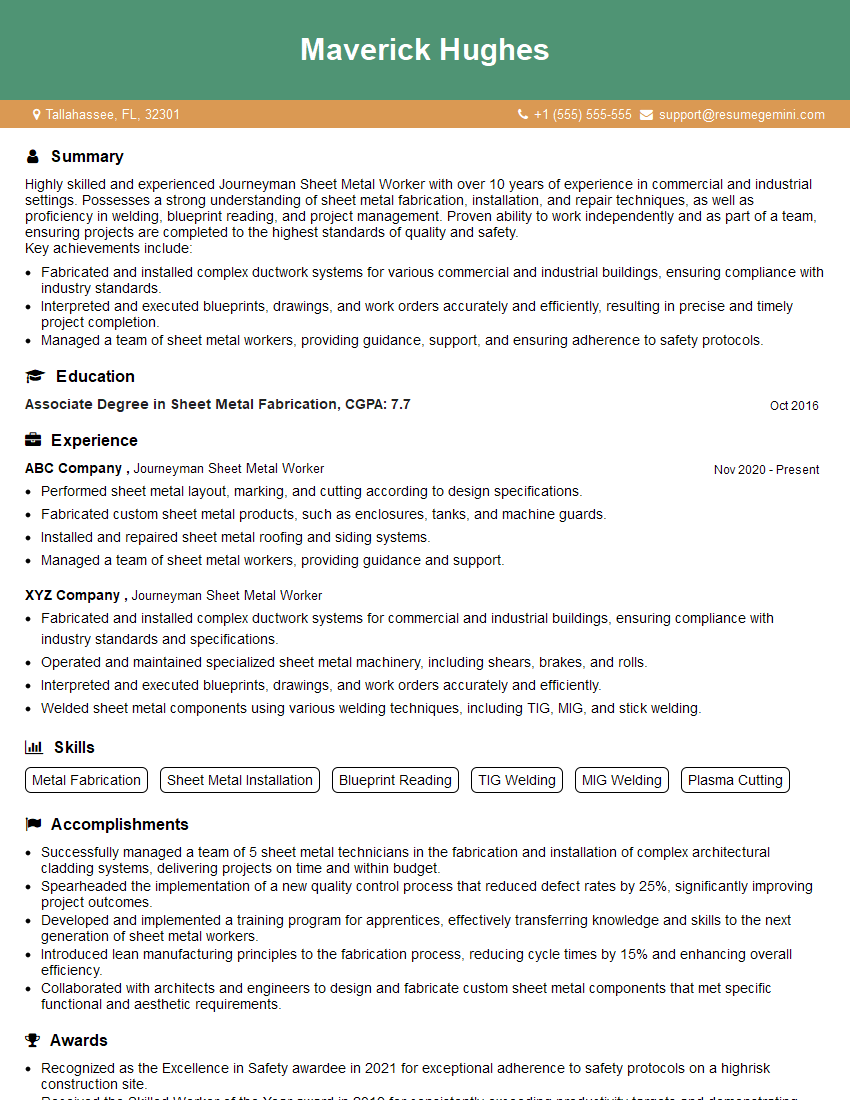

Maverick Hughes

Journeyman Sheet Metal Worker

Summary

Highly skilled and experienced Journeyman Sheet Metal Worker with over 10 years of experience in commercial and industrial settings. Possesses a strong understanding of sheet metal fabrication, installation, and repair techniques, as well as proficiency in welding, blueprint reading, and project management. Proven ability to work independently and as part of a team, ensuring projects are completed to the highest standards of quality and safety.

Key achievements include:

- Fabricated and installed complex ductwork systems for various commercial and industrial buildings, ensuring compliance with industry standards.

- Interpreted and executed blueprints, drawings, and work orders accurately and efficiently, resulting in precise and timely project completion.

- Managed a team of sheet metal workers, providing guidance, support, and ensuring adherence to safety protocols.

Education

Associate Degree in Sheet Metal Fabrication

October 2016

Skills

- Metal Fabrication

- Sheet Metal Installation

- Blueprint Reading

- TIG Welding

- MIG Welding

- Plasma Cutting

Work Experience

Journeyman Sheet Metal Worker

- Performed sheet metal layout, marking, and cutting according to design specifications.

- Fabricated custom sheet metal products, such as enclosures, tanks, and machine guards.

- Installed and repaired sheet metal roofing and siding systems.

- Managed a team of sheet metal workers, providing guidance and support.

Journeyman Sheet Metal Worker

- Fabricated and installed complex ductwork systems for commercial and industrial buildings, ensuring compliance with industry standards and specifications.

- Operated and maintained specialized sheet metal machinery, including shears, brakes, and rolls.

- Interpreted and executed blueprints, drawings, and work orders accurately and efficiently.

- Welded sheet metal components using various welding techniques, including TIG, MIG, and stick welding.

Accomplishments

- Successfully managed a team of 5 sheet metal technicians in the fabrication and installation of complex architectural cladding systems, delivering projects on time and within budget.

- Spearheaded the implementation of a new quality control process that reduced defect rates by 25%, significantly improving project outcomes.

- Developed and implemented a training program for apprentices, effectively transferring knowledge and skills to the next generation of sheet metal workers.

- Introduced lean manufacturing principles to the fabrication process, reducing cycle times by 15% and enhancing overall efficiency.

- Collaborated with architects and engineers to design and fabricate custom sheet metal components that met specific functional and aesthetic requirements.

Awards

- Recognized as the Excellence in Safety awardee in 2021 for exceptional adherence to safety protocols on a highrisk construction site.

- Received the Skilled Worker of the Year award in 2019 for consistently exceeding productivity targets and demonstrating exceptional craftsmanship.

- Awarded the Certificate of Merit for participating in the prestigious Sheet Metal Workers International Association (SMWIA) Skills Competition.

- Honored with the Outstanding Craftsmanship award for fabricating and installing a complex ornamental facade that met stringent aesthetic and structural requirements.

Certificates

- Journeyman Sheet Metal Worker Certification

- OSHA 30-Hour Construction Safety Certification

- NCCER Core Curriculum Certification

- Welding Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Journeyman Sheet Metal Worker

- Highlight your technical skills and experience in sheet metal fabrication, welding, and blueprint reading.

- Quantify your accomplishments and provide specific examples of projects you have worked on.

- Showcase your ability to work both independently and as part of a team.

- Obtain industry certifications, such as the Sheet Metal Worker Journeyman certification, to demonstrate your expertise.

- Network with other professionals in the industry to stay updated on the latest trends and technologies.

Essential Experience Highlights for a Strong Journeyman Sheet Metal Worker Resume

- Fabricate and install sheet metal components for various applications, including ductwork, roofing, and siding systems.

- Interpret blueprints, drawings, and work orders to ensure accurate execution of projects.

- Operate and maintain sheet metal machinery, such as shears, brakes, and rolls, to shape and form sheet metal components.

- Weld sheet metal components using various welding techniques, including TIG, MIG, and stick welding.

- Perform sheet metal layout, marking, and cutting according to design specifications.

- Inspect and repair sheet metal components and systems to ensure functionality and compliance with industry standards.

- Collaborate with other trades and work as part of a team to complete projects efficiently and effectively.

Frequently Asked Questions (FAQ’s) For Journeyman Sheet Metal Worker

What are the primary responsibilities of a Journeyman Sheet Metal Worker?

Journeyman Sheet Metal Workers are responsible for fabricating, installing, and repairing sheet metal components and systems. They interpret blueprints, operate sheet metal machinery, weld sheet metal components, and perform layout, marking, and cutting tasks. They also work with other trades to complete projects efficiently and effectively.

What skills are required to be a successful Journeyman Sheet Metal Worker?

Successful Journeyman Sheet Metal Workers possess strong technical skills in sheet metal fabrication, welding, and blueprint reading. They are also proficient in operating sheet metal machinery and have a good understanding of industry standards and safety protocols. They are able to work independently and as part of a team, and have excellent communication and problem-solving Fähigkeiten.

What are the career prospects for Journeyman Sheet Metal Workers?

Journeyman Sheet Metal Workers are in high demand in various industries, including construction, manufacturing, and transportation. They can advance their careers by becoming supervisors, project managers, or starting their own businesses. With additional training and experience, they can also specialize in areas such as architectural sheet metal, HVAC systems, or welding.

What is the average salary for a Journeyman Sheet Metal Worker?

The average salary for a Journeyman Sheet Metal Worker in the United States is around $55,000 per year. However, salaries can vary depending on experience, location, and industry.

What are the safety precautions that Journeyman Sheet Metal Workers must follow?

Journeyman Sheet Metal Workers must follow strict safety precautions to prevent accidents and injuries. These precautions include wearing appropriate safety gear, using machinery properly, and following established safety protocols. They must also be aware of potential hazards, such as sharp edges, hot surfaces, and electrical equipment.

What is the difference between a Journeyman Sheet Metal Worker and an Apprentice Sheet Metal Worker?

A Journeyman Sheet Metal Worker is a fully qualified and experienced sheet metal worker who has completed an apprenticeship program and passed a journeyman exam. An Apprentice Sheet Metal Worker is a trainee who is learning the trade under the supervision of a Journeyman. Apprentices typically complete a four-year program that includes both classroom and on-the-job training.

What are the benefits of becoming a unionized Journeyman Sheet Metal Worker?

Unionized Journeyman Sheet Metal Workers enjoy a number of benefits, including higher wages, better working conditions, and access to training and educational opportunities. Unions also provide their members with representation in grievance procedures and legal matters.

What are the challenges facing Journeyman Sheet Metal Workers?

Journeyman Sheet Metal Workers face a number of challenges, including the need to keep up with changing technologies and the increasing use of prefabricated components. They must also be able to work in a variety of environments, including heights, confined spaces, and extreme weather conditions.