Are you a seasoned Sheet Metal Installer seeking a new career path? Discover our professionally built Sheet Metal Installer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

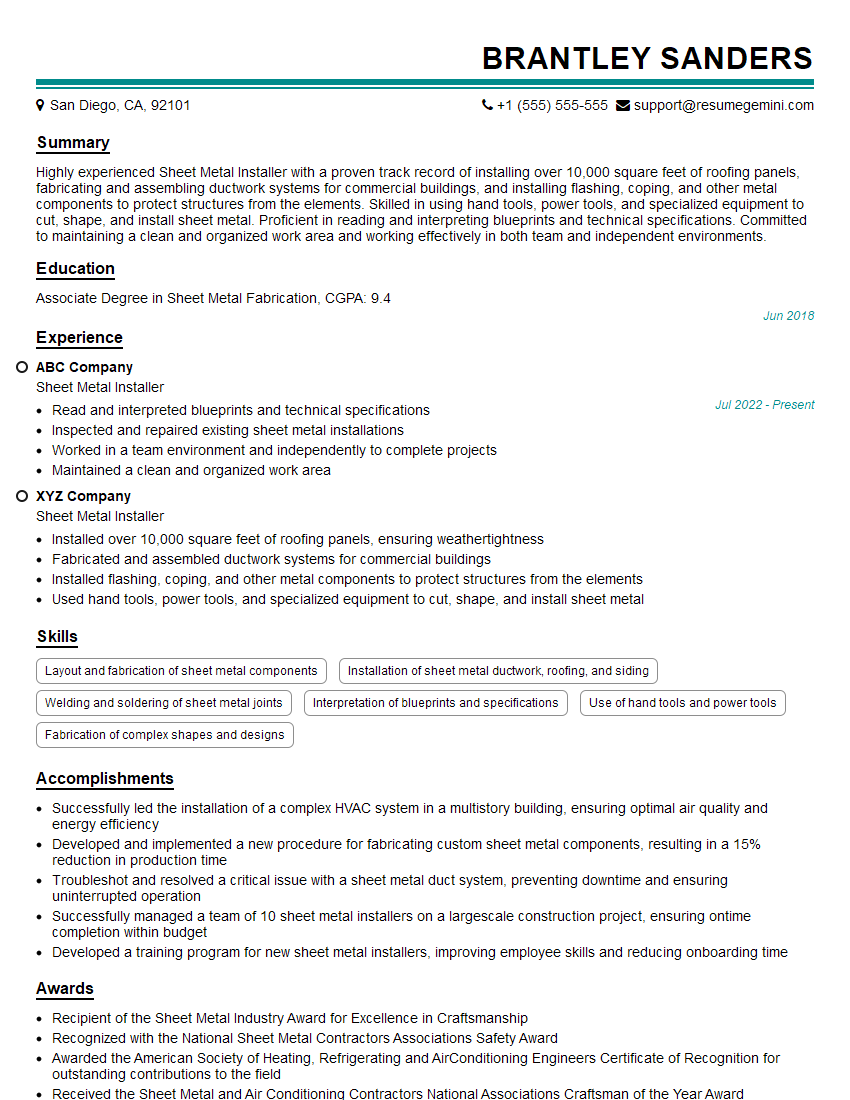

Brantley Sanders

Sheet Metal Installer

Summary

Highly experienced Sheet Metal Installer with a proven track record of installing over 10,000 square feet of roofing panels, fabricating and assembling ductwork systems for commercial buildings, and installing flashing, coping, and other metal components to protect structures from the elements. Skilled in using hand tools, power tools, and specialized equipment to cut, shape, and install sheet metal. Proficient in reading and interpreting blueprints and technical specifications. Committed to maintaining a clean and organized work area and working effectively in both team and independent environments.

Education

Associate Degree in Sheet Metal Fabrication

June 2018

Skills

- Layout and fabrication of sheet metal components

- Installation of sheet metal ductwork, roofing, and siding

- Welding and soldering of sheet metal joints

- Interpretation of blueprints and specifications

- Use of hand tools and power tools

- Fabrication of complex shapes and designs

Work Experience

Sheet Metal Installer

- Read and interpreted blueprints and technical specifications

- Inspected and repaired existing sheet metal installations

- Worked in a team environment and independently to complete projects

- Maintained a clean and organized work area

Sheet Metal Installer

- Installed over 10,000 square feet of roofing panels, ensuring weathertightness

- Fabricated and assembled ductwork systems for commercial buildings

- Installed flashing, coping, and other metal components to protect structures from the elements

- Used hand tools, power tools, and specialized equipment to cut, shape, and install sheet metal

Accomplishments

- Successfully led the installation of a complex HVAC system in a multistory building, ensuring optimal air quality and energy efficiency

- Developed and implemented a new procedure for fabricating custom sheet metal components, resulting in a 15% reduction in production time

- Troubleshot and resolved a critical issue with a sheet metal duct system, preventing downtime and ensuring uninterrupted operation

- Successfully managed a team of 10 sheet metal installers on a largescale construction project, ensuring ontime completion within budget

- Developed a training program for new sheet metal installers, improving employee skills and reducing onboarding time

Awards

- Recipient of the Sheet Metal Industry Award for Excellence in Craftsmanship

- Recognized with the National Sheet Metal Contractors Associations Safety Award

- Awarded the American Society of Heating, Refrigerating and AirConditioning Engineers Certificate of Recognition for outstanding contributions to the field

- Received the Sheet Metal and Air Conditioning Contractors National Associations Craftsman of the Year Award

Certificates

- Certified Sheet Metal Installer (SMACNA)

- OSHA 30-Hour Construction Safety Certification

- National Institute for Certification in Engineering Technologies (NICET) Level I or II

- Associated Builders and Contractors (ABC) Excellence in Construction Award

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Sheet Metal Installer

- Highlight your experience and skills in installing sheet metal roofing, ductwork, and other components.

- Showcase your proficiency in reading and interpreting technical drawings and blueprints.

- Emphasize your ability to work independently and as part of a team.

- Provide examples of complex projects you have completed, demonstrating your skills and expertise.

Essential Experience Highlights for a Strong Sheet Metal Installer Resume

- Layout and fabrication of sheet metal components

- Installation of sheet metal ductwork, roofing, and siding

- Welding and soldering of sheet metal joints

- Interpretation of blueprints and specifications

- Use of hand tools and power tools

- Fabrication of complex shapes and designs

- Inspection and repair of existing sheet metal installations

Frequently Asked Questions (FAQ’s) For Sheet Metal Installer

What are the primary responsibilities of a Sheet Metal Installer?

Sheet Metal Installers are responsible for installing, maintaining, and repairing sheet metal components in various structures, including roofing, ductwork, and siding.

What skills are required to become a Sheet Metal Installer?

Sheet Metal Installers typically possess skills in layout and fabrication of sheet metal components, installation of sheet metal ductwork, roofing, and siding, welding and soldering of sheet metal joints, and interpretation of blueprints and specifications.

What are the educational requirements for a Sheet Metal Installer?

While formal education requirements may vary, many Sheet Metal Installers hold an associate degree in Sheet Metal Fabrication or a related field.

What are the career prospects for Sheet Metal Installers?

Sheet Metal Installers can advance their careers by specializing in specific areas, such as architectural sheet metal or HVAC systems, or by pursuing management roles.

How can I improve my resume as a Sheet Metal Installer?

To improve your resume, focus on highlighting your experience and skills in sheet metal installation, use specific examples to demonstrate your capabilities, quantify your accomplishments with numbers, tailor your resume to each job you apply for, and proofread carefully for any errors.

What are the safety precautions that Sheet Metal Installers should follow?

Sheet Metal Installers must adhere to safety regulations, such as wearing appropriate protective gear, using tools and equipment correctly, and following established safety procedures to minimize risks.

What industry certifications are available for Sheet Metal Installers?

Sheet Metal Installers can obtain industry certifications to enhance their credibility and demonstrate their expertise, such as the OSHA 30-Hour Construction Safety and Health Certification or the Sheet Metal Workers’ International Association (SMWIA) certifications.