Are you a seasoned Cupola Patcher Helper seeking a new career path? Discover our professionally built Cupola Patcher Helper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

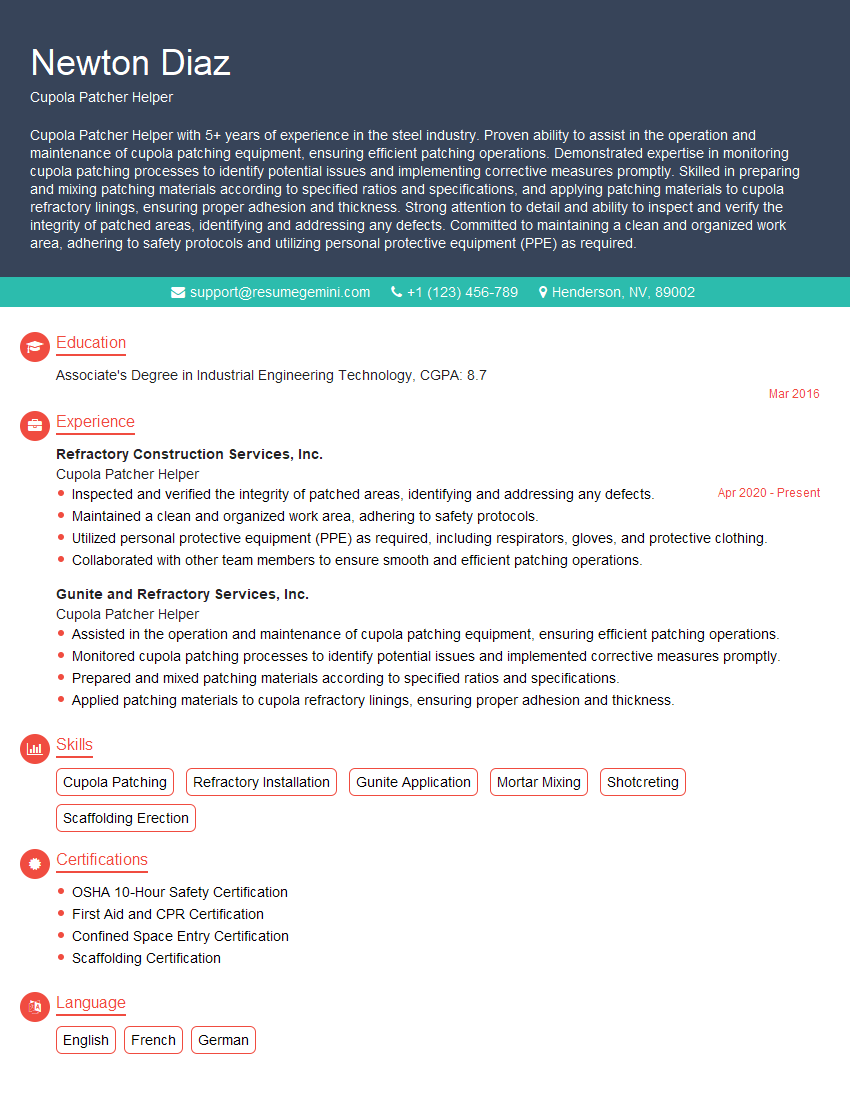

Newton Diaz

Cupola Patcher Helper

Summary

Cupola Patcher Helper with 5+ years of experience in the steel industry. Proven ability to assist in the operation and maintenance of cupola patching equipment, ensuring efficient patching operations. Demonstrated expertise in monitoring cupola patching processes to identify potential issues and implementing corrective measures promptly. Skilled in preparing and mixing patching materials according to specified ratios and specifications, and applying patching materials to cupola refractory linings, ensuring proper adhesion and thickness. Strong attention to detail and ability to inspect and verify the integrity of patched areas, identifying and addressing any defects. Committed to maintaining a clean and organized work area, adhering to safety protocols and utilizing personal protective equipment (PPE) as required.

Education

Associate’s Degree in Industrial Engineering Technology

March 2016

Skills

- Cupola Patching

- Refractory Installation

- Gunite Application

- Mortar Mixing

- Shotcreting

- Scaffolding Erection

Work Experience

Cupola Patcher Helper

- Inspected and verified the integrity of patched areas, identifying and addressing any defects.

- Maintained a clean and organized work area, adhering to safety protocols.

- Utilized personal protective equipment (PPE) as required, including respirators, gloves, and protective clothing.

- Collaborated with other team members to ensure smooth and efficient patching operations.

Cupola Patcher Helper

- Assisted in the operation and maintenance of cupola patching equipment, ensuring efficient patching operations.

- Monitored cupola patching processes to identify potential issues and implemented corrective measures promptly.

- Prepared and mixed patching materials according to specified ratios and specifications.

- Applied patching materials to cupola refractory linings, ensuring proper adhesion and thickness.

Certificates

- OSHA 10-Hour Safety Certification

- First Aid and CPR Certification

- Confined Space Entry Certification

- Scaffolding Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cupola Patcher Helper

- Highlight your experience working on cupola patching equipment and your ability to maintain it.

- Showcase your knowledge of refractory materials and their applications.

- Demonstrate your understanding of safety and health protocols related to cupola patching.

- Emphasize your teamwork and problem-solving skills.

- Consider including certifications or training programs that are relevant to the job.

Essential Experience Highlights for a Strong Cupola Patcher Helper Resume

- Assisted in the operation and maintenance of cupola patching equipment, ensuring efficient patching operations.

- Monitored cupola patching processes to identify potential issues and implemented corrective measures promptly.

- Prepared and mixed patching materials according to specified ratios and specifications.

- Applied patching materials to cupola refractory linings, ensuring proper adhesion and thickness.

- Inspected and verified the integrity of patched areas, identifying and addressing any defects.

- Maintained a clean and organized work area, adhering to safety protocols.

- Utilized personal protective equipment (PPE) as required, including respirators, gloves, and protective clothing.

Frequently Asked Questions (FAQ’s) For Cupola Patcher Helper

What are the primary duties and responsibilities of a Cupola Patcher Helper?

Cupola Patcher Helpers assist in the operation and maintenance of cupola patching equipment, monitor cupola patching processes, prepare and mix patching materials, apply patching materials to cupola refractory linings, and inspect and verify the integrity of patched areas.

What is the typical work environment for a Cupola Patcher Helper?

Cupola Patcher Helpers typically work in industrial settings, such as foundries and steel mills. The work environment may be hot, noisy, and dusty, and may involve working with hazardous materials.

What are the qualifications for becoming a Cupola Patcher Helper?

Cupola Patcher Helpers typically have a high school diploma or equivalent, and may have experience working in the steel industry or with refractory materials. They should have good physical strength and stamina, as well as the ability to work in a team environment.

What is the career outlook for Cupola Patcher Helpers?

The career outlook for Cupola Patcher Helpers is expected to be good over the next few years, as there is a growing demand for qualified workers in the steel industry.

What are the safety precautions that a Cupola Patcher Helper should take?

Cupola Patcher Helpers should wear appropriate personal protective equipment (PPE), including respirators, gloves, and protective clothing. They should also be aware of the potential hazards of working with hazardous materials, and should take precautions to avoid accidents.

What are the key skills that a Cupola Patcher Helper should have?

Cupola Patcher Helpers should have good physical strength and stamina, as well as the ability to work in a team environment. They should also have the following skills:

– Ability to operate and maintain cupola patching equipment

– Knowledge of refractory materials and their applications

– Understanding of safety and health protocols related to cupola patching

– Teamwork and problem-solving skills