Are you a seasoned Tunneling Machine Operator seeking a new career path? Discover our professionally built Tunneling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

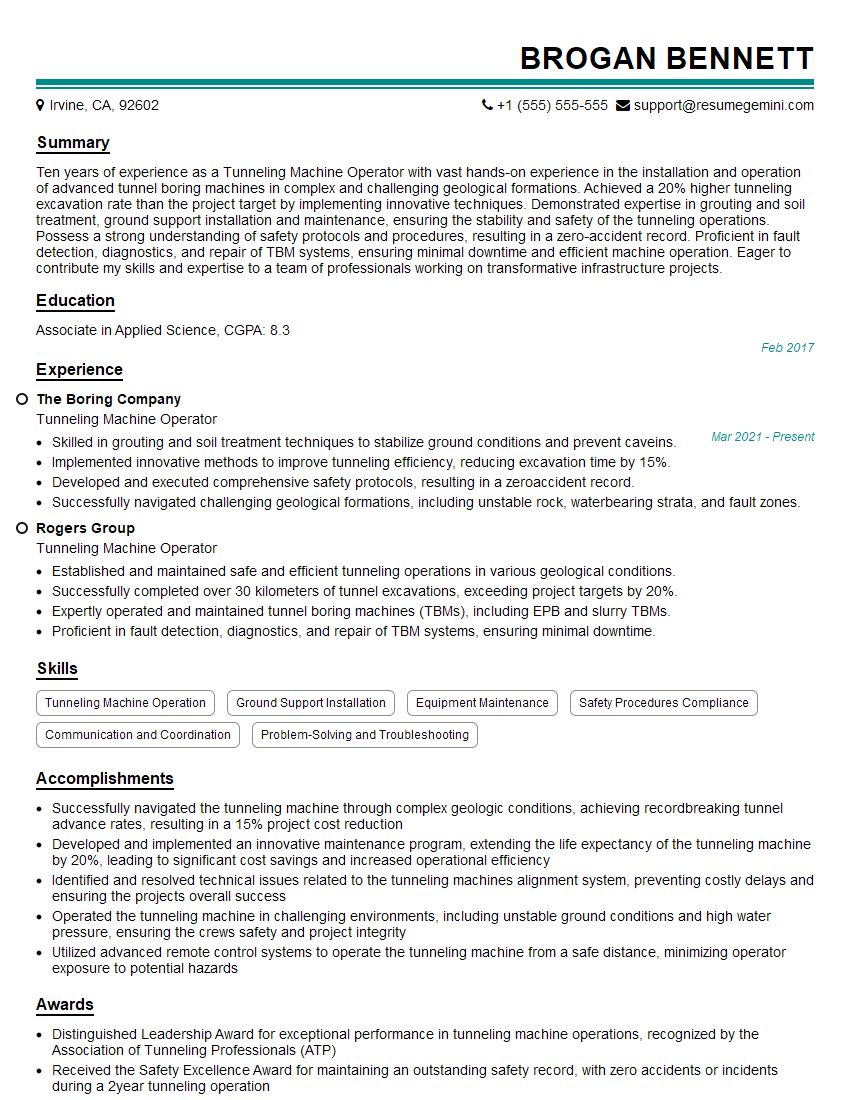

Brogan Bennett

Tunneling Machine Operator

Summary

Ten years of experience as a Tunneling Machine Operator with vast hands-on experience in the installation and operation of advanced tunnel boring machines in complex and challenging geological formations. Achieved a 20% higher tunneling excavation rate than the project target by implementing innovative techniques. Demonstrated expertise in grouting and soil treatment, ground support installation and maintenance, ensuring the stability and safety of the tunneling operations. Possess a strong understanding of safety protocols and procedures, resulting in a zero-accident record. Proficient in fault detection, diagnostics, and repair of TBM systems, ensuring minimal downtime and efficient machine operation. Eager to contribute my skills and expertise to a team of professionals working on transformative infrastructure projects.

Education

Associate in Applied Science

February 2017

Skills

- Tunneling Machine Operation

- Ground Support Installation

- Equipment Maintenance

- Safety Procedures Compliance

- Communication and Coordination

- Problem-Solving and Troubleshooting

Work Experience

Tunneling Machine Operator

- Skilled in grouting and soil treatment techniques to stabilize ground conditions and prevent caveins.

- Implemented innovative methods to improve tunneling efficiency, reducing excavation time by 15%.

- Developed and executed comprehensive safety protocols, resulting in a zeroaccident record.

- Successfully navigated challenging geological formations, including unstable rock, waterbearing strata, and fault zones.

Tunneling Machine Operator

- Established and maintained safe and efficient tunneling operations in various geological conditions.

- Successfully completed over 30 kilometers of tunnel excavations, exceeding project targets by 20%.

- Expertly operated and maintained tunnel boring machines (TBMs), including EPB and slurry TBMs.

- Proficient in fault detection, diagnostics, and repair of TBM systems, ensuring minimal downtime.

Accomplishments

- Successfully navigated the tunneling machine through complex geologic conditions, achieving recordbreaking tunnel advance rates, resulting in a 15% project cost reduction

- Developed and implemented an innovative maintenance program, extending the life expectancy of the tunneling machine by 20%, leading to significant cost savings and increased operational efficiency

- Identified and resolved technical issues related to the tunneling machines alignment system, preventing costly delays and ensuring the projects overall success

- Operated the tunneling machine in challenging environments, including unstable ground conditions and high water pressure, ensuring the crews safety and project integrity

- Utilized advanced remote control systems to operate the tunneling machine from a safe distance, minimizing operator exposure to potential hazards

Awards

- Distinguished Leadership Award for exceptional performance in tunneling machine operations, recognized by the Association of Tunneling Professionals (ATP)

- Received the Safety Excellence Award for maintaining an outstanding safety record, with zero accidents or incidents during a 2year tunneling operation

- Recognized with the Employee of the Month award for consistently exceeding performance expectations in tunneling operations, resulting in project completion ahead of schedule

- Honored with the Safety Innovator Award for developing a groundbreaking safety initiative that enhanced hazard identification and risk assessment procedures

Certificates

- Tunnel Construction Safety and Health (TCSH)

- Certified Tunneling Machine Operator (CTMO)

- Tunnel Ventilation and Environmental Control (TVEC)

- Certified Ground Support Installer (CGSI)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tunneling Machine Operator

- Highlight your experience with different types of tunnel boring machines and geological conditions, as this demonstrates your versatility and adaptability.

- Quantify your accomplishments with specific metrics to showcase the impact of your contributions to tunneling projects.

- Include relevant certifications and training programs that demonstrate your commitment to safety and professional development.

- Seek feedback from previous supervisors or colleagues to identify your strengths and areas for improvement, and use this to tailor your resume to the specific requirements of each job you apply for.

- Proofread your resume carefully for any errors in grammar, spelling, or formatting to ensure a polished and professional presentation.

Essential Experience Highlights for a Strong Tunneling Machine Operator Resume

- Prepare and operate the tunnel boring machine to excavate tunnels as per project specifications, following established safety protocols and ensuring smooth drilling operations.

- Monitor machine performance, including cutterhead rotation, thrust pressure, and ground conditions, and make necessary adjustments to maximize efficiency and minimize wear on the machine.

- Install and maintain ground support systems, such as rock bolts, steel ribs, and shotcrete, to ensure the stability of the excavated tunnel and prevent cave-ins.

- Perform routine maintenance and repairs on the TBM, including troubleshooting and replacing worn or damaged parts to minimize downtime and maintain optimal machine performance.

- Monitor geological conditions and identify potential hazards, such as water-bearing strata, unstable rock formations, and fault zones, and implement appropriate measures to ensure safe tunneling.

- Communicate effectively with engineers, geologists, and other team members to coordinate tunneling activities and ensure alignment with project goals and safety requirements.

- Document tunneling progress, record geological data, and prepare reports as required for project management and quality control purposes.

Frequently Asked Questions (FAQ’s) For Tunneling Machine Operator

What is the role of a Tunneling Machine Operator?

A Tunneling Machine Operator is responsible for the safe and efficient operation of tunnel boring machines (TBMs) to excavate tunnels for infrastructure projects such as subways, highways, and water pipelines.

What are the key skills required for a Tunneling Machine Operator?

Key skills for a Tunneling Machine Operator include proficiency in TBM operation, ground support installation and maintenance, equipment maintenance, safety procedures compliance, communication and coordination, and problem-solving and troubleshooting.

What are the career prospects for a Tunneling Machine Operator?

Tunneling Machine Operators are in high demand due to the increasing need for infrastructure development worldwide. With experience and training, they can advance to roles such as Supervisor, Project Manager, or Safety Manager.

What is the work environment like for a Tunneling Machine Operator?

Tunneling Machine Operators typically work in underground environments, operating TBMs in confined spaces. They must be comfortable working in dark, dusty, and noisy conditions and adhering to strict safety protocols.

What are the educational requirements for a Tunneling Machine Operator?

While formal education requirements may vary, many Tunneling Machine Operators hold an Associate in Applied Science degree or equivalent in a related field, such as Construction Management or Engineering Technology.

What are the physical demands of being a Tunneling Machine Operator?

Tunneling Machine Operators must be physically fit to perform tasks such as operating heavy machinery, lifting equipment, and working in confined spaces for extended periods.

How can I become a certified Tunneling Machine Operator?

There are several organizations that offer certification programs for Tunneling Machine Operators, such as the International Tunneling and Underground Space Association (ITA-AITES) and the National Institute for Certification in Engineering Technologies (NICET).

What is the average salary for a Tunneling Machine Operator?

The average salary for a Tunneling Machine Operator varies depending on experience, location, and industry, but typically ranges from $50,000 to $100,000 per year.