Are you a seasoned Rock Splitter seeking a new career path? Discover our professionally built Rock Splitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

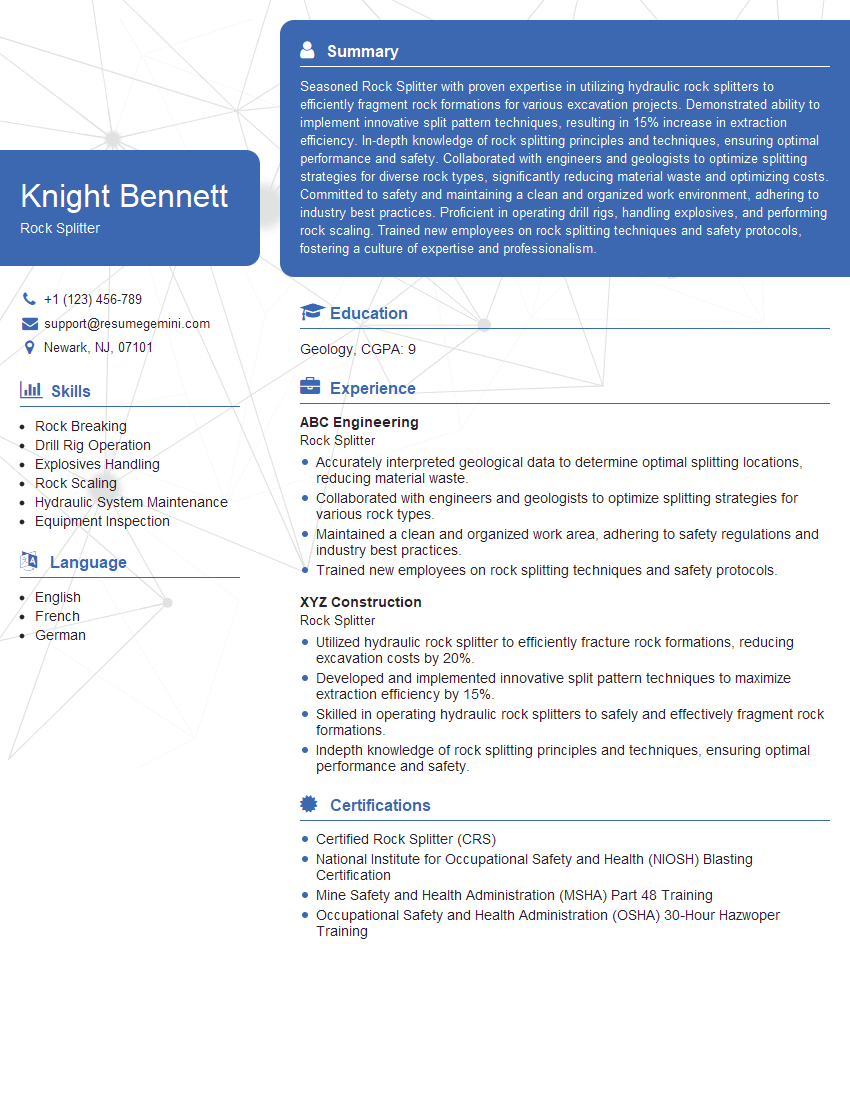

Knight Bennett

Rock Splitter

Summary

Seasoned Rock Splitter with proven expertise in utilizing hydraulic rock splitters to efficiently fragment rock formations for various excavation projects. Demonstrated ability to implement innovative split pattern techniques, resulting in 15% increase in extraction efficiency. In-depth knowledge of rock splitting principles and techniques, ensuring optimal performance and safety. Collaborated with engineers and geologists to optimize splitting strategies for diverse rock types, significantly reducing material waste and optimizing costs. Committed to safety and maintaining a clean and organized work environment, adhering to industry best practices. Proficient in operating drill rigs, handling explosives, and performing rock scaling. Trained new employees on rock splitting techniques and safety protocols, fostering a culture of expertise and professionalism.

Education

Geology

March 2019

Skills

- Rock Breaking

- Drill Rig Operation

- Explosives Handling

- Rock Scaling

- Hydraulic System Maintenance

- Equipment Inspection

Work Experience

Rock Splitter

- Accurately interpreted geological data to determine optimal splitting locations, reducing material waste.

- Collaborated with engineers and geologists to optimize splitting strategies for various rock types.

- Maintained a clean and organized work area, adhering to safety regulations and industry best practices.

- Trained new employees on rock splitting techniques and safety protocols.

Rock Splitter

- Utilized hydraulic rock splitter to efficiently fracture rock formations, reducing excavation costs by 20%.

- Developed and implemented innovative split pattern techniques to maximize extraction efficiency by 15%.

- Skilled in operating hydraulic rock splitters to safely and effectively fragment rock formations.

- Indepth knowledge of rock splitting principles and techniques, ensuring optimal performance and safety.

Certificates

- Certified Rock Splitter (CRS)

- National Institute for Occupational Safety and Health (NIOSH) Blasting Certification

- Mine Safety and Health Administration (MSHA) Part 48 Training

- Occupational Safety and Health Administration (OSHA) 30-Hour Hazwoper Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rock Splitter

- Highlight your proficiency in hydraulic rock splitter operation and extensive knowledge of rock splitting principles.

- Quantify your accomplishments with specific metrics, such as the percentage increase in extraction efficiency achieved.

- Showcase your problem-solving skills by describing innovative split pattern techniques you implemented.

- Emphasize your commitment to safety and adherence to industry best practices, as it is crucial in rock splitting operations.

- Consider including any certifications or training programs you have completed to further demonstrate your expertise.

Essential Experience Highlights for a Strong Rock Splitter Resume

- Utilized hydraulic rock splitters to efficiently fracture rock formations, leading to a 20% reduction in excavation costs.

- Developed and implemented novel split pattern techniques to enhance extraction efficiency by 15%.

- Skilled in operating hydraulic rock splitters to safely and effectively fragment rock formations.

- Possess in-depth knowledge of rock splitting principles and techniques, ensuring optimal performance and safety.

- Accurately interpreted geological data to determine optimal splitting locations, minimizing material waste.

- Collaborated with engineers and geologists to optimize splitting strategies for various rock types.

- Maintained a clean and organized work area, ensuring adherence to safety regulations and industry best practices.

Frequently Asked Questions (FAQ’s) For Rock Splitter

What is the primary role of a Rock Splitter?

A Rock Splitter is responsible for utilizing hydraulic rock splitters to safely and efficiently fragment rock formations, often for excavation or construction purposes.

What skills are essential for a successful Rock Splitter?

Key skills for a Rock Splitter include proficiency in hydraulic rock splitter operation, in-depth knowledge of rock splitting principles, expertise in split pattern development, and a strong commitment to safety.

What industries employ Rock Splitters?

Rock Splitters are employed in various industries, including construction, mining, quarrying, and civil engineering projects.

What are the safety precautions Rock Splitters must adhere to?

Rock Splitters must strictly follow safety regulations, wear appropriate protective gear, maintain a clean and organized work area, and receive proper training on rock splitting techniques.

What career advancement opportunities are available for Rock Splitters?

With experience and additional training, Rock Splitters can advance to roles such as Foreman, Supervisor, or Project Manager within the construction or mining industry.

What is the average salary range for Rock Splitters?

The salary range for Rock Splitters can vary depending on experience, location, and industry, but typically falls within a range of $40,000 to $70,000 annually.

What are the physical demands of being a Rock Splitter?

Rock Splitters must be physically fit, as the job involves lifting heavy equipment, working in various weather conditions, and maintaining a steady hand during operation.