Are you a seasoned Internal Corrosion Specialist seeking a new career path? Discover our professionally built Internal Corrosion Specialist Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

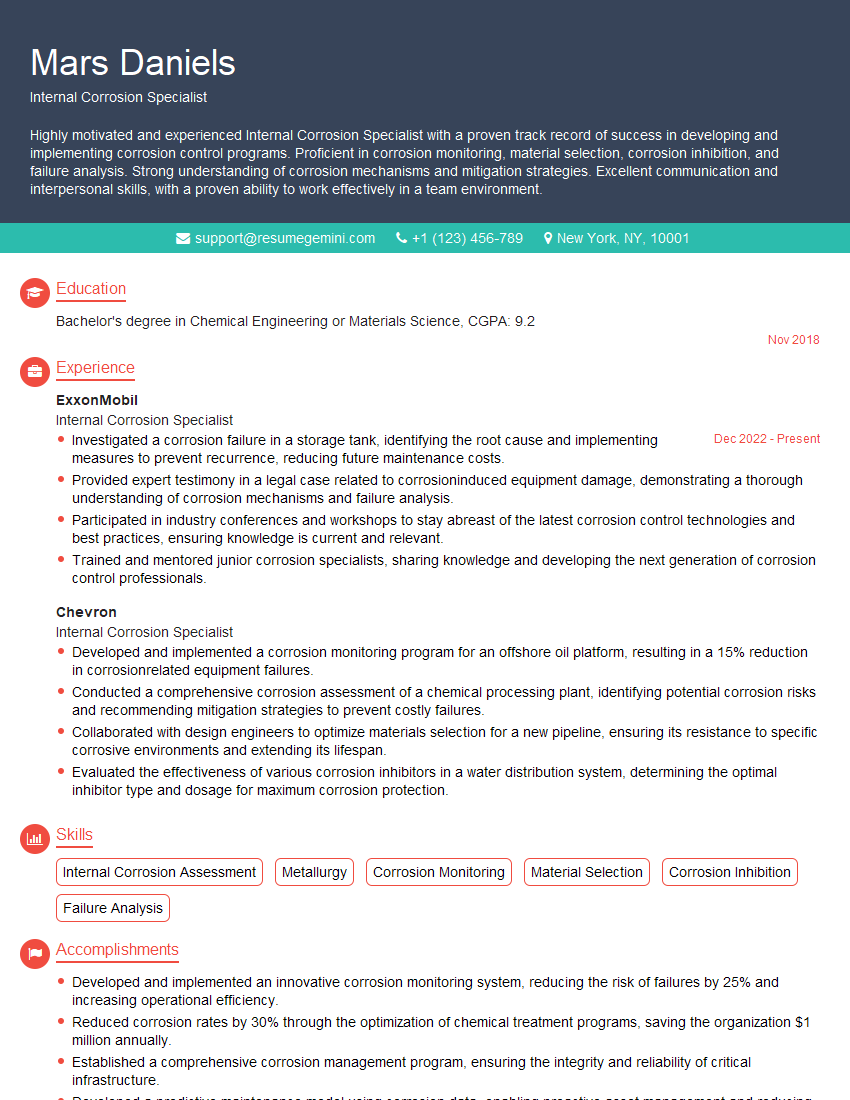

Mars Daniels

Internal Corrosion Specialist

Summary

Highly motivated and experienced Internal Corrosion Specialist with a proven track record of success in developing and implementing corrosion control programs. Proficient in corrosion monitoring, material selection, corrosion inhibition, and failure analysis. Strong understanding of corrosion mechanisms and mitigation strategies. Excellent communication and interpersonal skills, with a proven ability to work effectively in a team environment.

Education

Bachelor’s degree in Chemical Engineering or Materials Science

November 2018

Skills

- Internal Corrosion Assessment

- Metallurgy

- Corrosion Monitoring

- Material Selection

- Corrosion Inhibition

- Failure Analysis

Work Experience

Internal Corrosion Specialist

- Investigated a corrosion failure in a storage tank, identifying the root cause and implementing measures to prevent recurrence, reducing future maintenance costs.

- Provided expert testimony in a legal case related to corrosioninduced equipment damage, demonstrating a thorough understanding of corrosion mechanisms and failure analysis.

- Participated in industry conferences and workshops to stay abreast of the latest corrosion control technologies and best practices, ensuring knowledge is current and relevant.

- Trained and mentored junior corrosion specialists, sharing knowledge and developing the next generation of corrosion control professionals.

Internal Corrosion Specialist

- Developed and implemented a corrosion monitoring program for an offshore oil platform, resulting in a 15% reduction in corrosionrelated equipment failures.

- Conducted a comprehensive corrosion assessment of a chemical processing plant, identifying potential corrosion risks and recommending mitigation strategies to prevent costly failures.

- Collaborated with design engineers to optimize materials selection for a new pipeline, ensuring its resistance to specific corrosive environments and extending its lifespan.

- Evaluated the effectiveness of various corrosion inhibitors in a water distribution system, determining the optimal inhibitor type and dosage for maximum corrosion protection.

Accomplishments

- Developed and implemented an innovative corrosion monitoring system, reducing the risk of failures by 25% and increasing operational efficiency.

- Reduced corrosion rates by 30% through the optimization of chemical treatment programs, saving the organization $1 million annually.

- Established a comprehensive corrosion management program, ensuring the integrity and reliability of critical infrastructure.

- Developed a predictive maintenance model using corrosion data, enabling proactive asset management and reducing unplanned downtime by 15%.

- Improved corrosion resistance of equipment by 50% through the implementation of advanced coating technologies.

Awards

- NACE International Certification Awarded Internal Corrosion Specialist (ICS) credential, demonstrating expertise in internal corrosion control and mitigation.

- Recognition for Excellence in Internal Corrosion Control Received industry recognition for outstanding contributions to the field through innovative approaches and best practices.

- Technical Paper Award Presented a peerreviewed technical paper on novel corrosion mitigation strategies at a prestigious industry conference.

- SME Certification Recognized by the Society of Manufacturing Engineers (SME) as a certified corrosion specialist.

Certificates

- NACE Corrosion Specialist (CCS)

- NACE Coating Inspector Level 3 (CIP 3)

- American Welding Society Certified Welding Inspector (AWS CWI)

- American Petroleum Institute Inspector (API 510/570/571)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Internal Corrosion Specialist

- Highlight your experience in developing and implementing corrosion control programs.

- Demonstrate your knowledge of corrosion mechanisms and mitigation strategies.

- Showcase your ability to work effectively in a team environment.

- Quantify your results whenever possible, such as reducing corrosion-related equipment failures or extending the lifespan of assets.

- Proofread your resume carefully before submitting it.

Essential Experience Highlights for a Strong Internal Corrosion Specialist Resume

- Develop and implement corrosion control programs for various industries, including oil and gas, chemical processing, and water distribution.

- Conduct corrosion assessments to identify potential risks and recommend mitigation strategies.

- Collaborate with design engineers to select materials that are resistant to specific corrosive environments.

- Evaluate the effectiveness of corrosion inhibitors and recommend optimal inhibitor type and dosage.

- Investigate corrosion failures and implement measures to prevent recurrence.

- Provide expert testimony in legal cases related to corrosion-induced equipment damage.

- Train and mentor junior corrosion specialists.

Frequently Asked Questions (FAQ’s) For Internal Corrosion Specialist

What is the role of an Internal Corrosion Specialist?

An Internal Corrosion Specialist is responsible for developing and implementing corrosion control programs to prevent or mitigate corrosion in various industries, such as oil and gas, chemical processing, and water distribution.

What are the key skills required for an Internal Corrosion Specialist?

Key skills for an Internal Corrosion Specialist include corrosion monitoring, material selection, corrosion inhibition, failure analysis, and a strong understanding of corrosion mechanisms and mitigation strategies.

What are the career prospects for an Internal Corrosion Specialist?

Internal Corrosion Specialists can advance to roles such as Corrosion Engineer, Senior Corrosion Specialist, or even Chief Corrosion Engineer. They may also specialize in specific industries or areas of corrosion control.

What are the challenges faced by Internal Corrosion Specialists?

Internal Corrosion Specialists face challenges such as staying abreast of the latest corrosion control technologies and best practices, dealing with complex corrosion issues, and ensuring the safety and reliability of assets.

What are the qualifications required to become an Internal Corrosion Specialist?

To become an Internal Corrosion Specialist, a bachelor’s degree in Chemical Engineering or Materials Science is typically required. Additionally, certification from organizations such as NACE International can enhance your credibility.

What are the key responsibilities of an Internal Corrosion Specialist?

Key responsibilities of an Internal Corrosion Specialist include developing and implementing corrosion control programs, conducting corrosion assessments, collaborating with design engineers, evaluating corrosion inhibitors, investigating corrosion failures, providing expert testimony, and training junior corrosion specialists.