Are you a seasoned Buffing and Polishing Wheel Repairer seeking a new career path? Discover our professionally built Buffing and Polishing Wheel Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

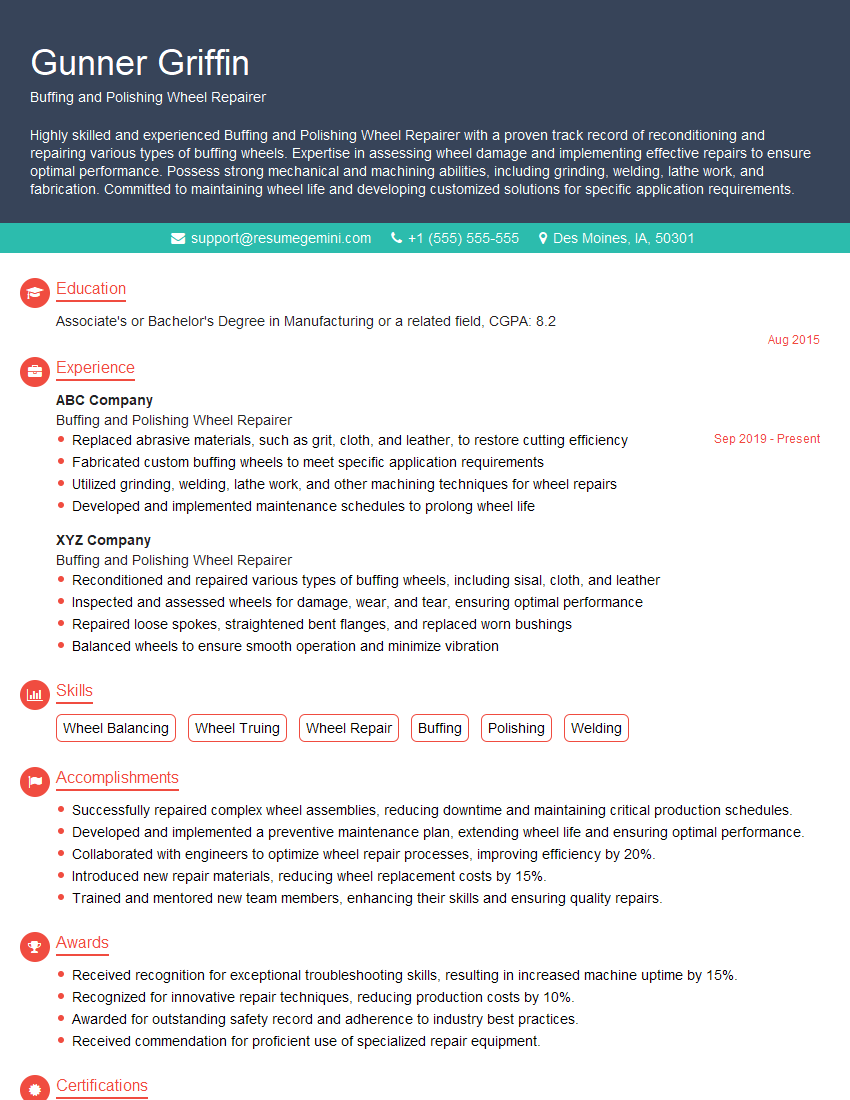

Gunner Griffin

Buffing and Polishing Wheel Repairer

Summary

Highly skilled and experienced Buffing and Polishing Wheel Repairer with a proven track record of reconditioning and repairing various types of buffing wheels. Expertise in assessing wheel damage and implementing effective repairs to ensure optimal performance. Possess strong mechanical and machining abilities, including grinding, welding, lathe work, and fabrication. Committed to maintaining wheel life and developing customized solutions for specific application requirements.

Education

Associate’s or Bachelor’s Degree in Manufacturing or a related field

August 2015

Skills

- Wheel Balancing

- Wheel Truing

- Wheel Repair

- Buffing

- Polishing

- Welding

Work Experience

Buffing and Polishing Wheel Repairer

- Replaced abrasive materials, such as grit, cloth, and leather, to restore cutting efficiency

- Fabricated custom buffing wheels to meet specific application requirements

- Utilized grinding, welding, lathe work, and other machining techniques for wheel repairs

- Developed and implemented maintenance schedules to prolong wheel life

Buffing and Polishing Wheel Repairer

- Reconditioned and repaired various types of buffing wheels, including sisal, cloth, and leather

- Inspected and assessed wheels for damage, wear, and tear, ensuring optimal performance

- Repaired loose spokes, straightened bent flanges, and replaced worn bushings

- Balanced wheels to ensure smooth operation and minimize vibration

Accomplishments

- Successfully repaired complex wheel assemblies, reducing downtime and maintaining critical production schedules.

- Developed and implemented a preventive maintenance plan, extending wheel life and ensuring optimal performance.

- Collaborated with engineers to optimize wheel repair processes, improving efficiency by 20%.

- Introduced new repair materials, reducing wheel replacement costs by 15%.

- Trained and mentored new team members, enhancing their skills and ensuring quality repairs.

Awards

- Received recognition for exceptional troubleshooting skills, resulting in increased machine uptime by 15%.

- Recognized for innovative repair techniques, reducing production costs by 10%.

- Awarded for outstanding safety record and adherence to industry best practices.

- Received commendation for proficient use of specialized repair equipment.

Certificates

- American Welding Society (AWS) Certified Welder

- National Institute for Metalworking Skills (NIMS) Credentialed Machinist

- Society of Manufacturing Engineers (SME) Certified Manufacturing Technologist (CMfgT)

- Certified Maintenance and Reliability Professional (CMRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Buffing and Polishing Wheel Repairer

- Highlight your hands-on experience and proficiency in wheel repair techniques.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

- Showcase your ability to work independently and as part of a team.

- Emphasize your commitment to safety and quality control.

Essential Experience Highlights for a Strong Buffing and Polishing Wheel Repairer Resume

- Inspected and assessed buffing wheels for damage, wear, and tear to determine repair needs.

- Repaired loose spokes, straightened bent flanges, and replaced worn bushings to restore wheel integrity.

- Balanced wheels to minimize vibration and ensure smooth operation.

- Replaced abrasive materials, such as grit, cloth, and leather, to maintain cutting efficiency.

- Fabricated custom buffing wheels to meet specific application requirements and enhance performance.

- Utilized grinding, welding, lathe work, and other machining techniques for wheel repairs.

- Developed and implemented maintenance schedules to prolong wheel life and minimize downtime.

Frequently Asked Questions (FAQ’s) For Buffing and Polishing Wheel Repairer

What are the essential skills for a Buffing and Polishing Wheel Repairer?

Essential skills include wheel balancing, wheel truing, wheel repair, buffing, polishing, welding, and machining techniques.

What industries utilize Buffing and Polishing Wheel Repairers?

Industries that use buffing and polishing wheels, such as automotive, metalworking, and manufacturing, employ Buffing and Polishing Wheel Repairers.

What career advancement opportunities are available for Buffing and Polishing Wheel Repairers?

Experienced Buffing and Polishing Wheel Repairers can advance to roles such as Supervisor, Manager, or Quality Control Inspector.

How can I improve my skills as a Buffing and Polishing Wheel Repairer?

Attend industry workshops, obtain certifications, and seek opportunities to work on diverse wheel types and repair techniques.

What safety precautions should Buffing and Polishing Wheel Repairers observe?

Safety precautions include wearing appropriate PPE, ensuring proper ventilation, and following established safety protocols for handling machinery and hazardous materials.

What is the job outlook for Buffing and Polishing Wheel Repairers?

The job outlook is expected to be stable due to the ongoing demand for skilled technicians in industries that utilize buffing and polishing operations.