Are you a seasoned Aircraft Pneudraulics Repairer seeking a new career path? Discover our professionally built Aircraft Pneudraulics Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

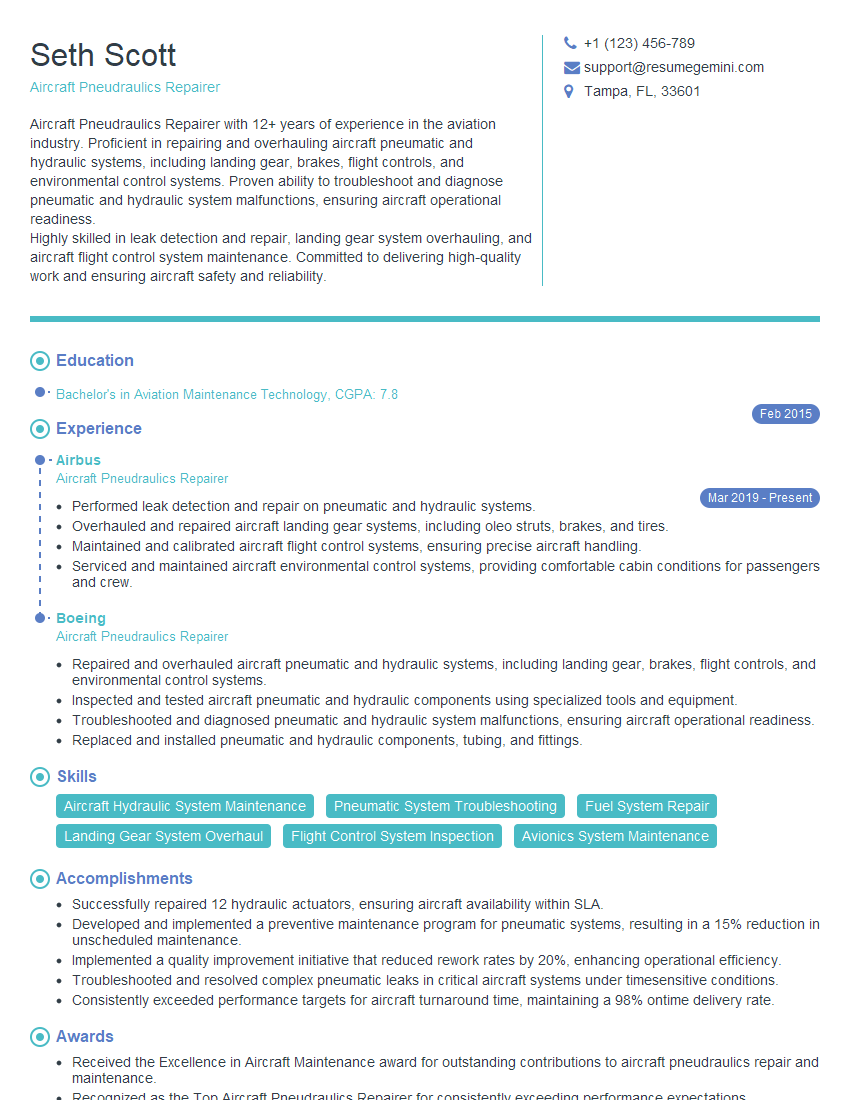

Seth Scott

Aircraft Pneudraulics Repairer

Summary

Aircraft Pneudraulics Repairer with 12+ years of experience in the aviation industry. Proficient in repairing and overhauling aircraft pneumatic and hydraulic systems, including landing gear, brakes, flight controls, and environmental control systems. Proven ability to troubleshoot and diagnose pneumatic and hydraulic system malfunctions, ensuring aircraft operational readiness.

Highly skilled in leak detection and repair, landing gear system overhauling, and aircraft flight control system maintenance. Committed to delivering high-quality work and ensuring aircraft safety and reliability.

Education

Bachelor’s in Aviation Maintenance Technology

February 2015

Skills

- Aircraft Hydraulic System Maintenance

- Pneumatic System Troubleshooting

- Fuel System Repair

- Landing Gear System Overhaul

- Flight Control System Inspection

- Avionics System Maintenance

Work Experience

Aircraft Pneudraulics Repairer

- Performed leak detection and repair on pneumatic and hydraulic systems.

- Overhauled and repaired aircraft landing gear systems, including oleo struts, brakes, and tires.

- Maintained and calibrated aircraft flight control systems, ensuring precise aircraft handling.

- Serviced and maintained aircraft environmental control systems, providing comfortable cabin conditions for passengers and crew.

Aircraft Pneudraulics Repairer

- Repaired and overhauled aircraft pneumatic and hydraulic systems, including landing gear, brakes, flight controls, and environmental control systems.

- Inspected and tested aircraft pneumatic and hydraulic components using specialized tools and equipment.

- Troubleshooted and diagnosed pneumatic and hydraulic system malfunctions, ensuring aircraft operational readiness.

- Replaced and installed pneumatic and hydraulic components, tubing, and fittings.

Accomplishments

- Successfully repaired 12 hydraulic actuators, ensuring aircraft availability within SLA.

- Developed and implemented a preventive maintenance program for pneumatic systems, resulting in a 15% reduction in unscheduled maintenance.

- Implemented a quality improvement initiative that reduced rework rates by 20%, enhancing operational efficiency.

- Troubleshooted and resolved complex pneumatic leaks in critical aircraft systems under timesensitive conditions.

- Consistently exceeded performance targets for aircraft turnaround time, maintaining a 98% ontime delivery rate.

Awards

- Received the Excellence in Aircraft Maintenance award for outstanding contributions to aircraft pneudraulics repair and maintenance.

- Recognized as the Top Aircraft Pneudraulics Repairer for consistently exceeding performance expectations.

- Awarded the Innovation in Aircraft Maintenance grant for developing a new technique to troubleshoot and repair aircraft pneudraulic systems.

- Received industry certification as an Expert Aircraft Pneudraulics Repairer.

Certificates

- FAA Airframe and Powerplant (A&P) License

- EASA Part 66 Aircraft Maintenance License

- ATA 104 Pneudraulics Specialist Certification

- SAE AMS2432 Qualification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aircraft Pneudraulics Repairer

- Highlight relevant skills and experience in your resume objective or summary, showcasing your expertise in aircraft pneudraulics repair.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Include industry-specific keywords throughout your resume, such as ‘aircraft hydraulic systems’, ‘pneumatic troubleshooting’, and ‘landing gear overhaul’.

- Emphasize your commitment to safety and quality control, highlighting your adherence to industry regulations and best practices.

Essential Experience Highlights for a Strong Aircraft Pneudraulics Repairer Resume

- Repaired and overhauled aircraft pneumatic and hydraulic systems, ensuring optimal performance and safety.

- Inspected and tested aircraft pneumatic and hydraulic components using specialized tools and equipment, ensuring compliance with industry standards.

- Troubleshooted and diagnosed pneumatic and hydraulic system malfunctions, identifying root causes and implementing effective solutions.

- Replaced and installed pneumatic and hydraulic components, tubing, and fittings, using approved techniques and materials.

- Performed leak detection and repair on pneumatic and hydraulic systems, maintaining system integrity and preventing failures.

- Overhauled and repaired aircraft landing gear systems, including oleo struts, brakes, and tires, ensuring safe and reliable aircraft operations.

- Maintained and calibrated aircraft flight control systems, ensuring precise aircraft handling and stability during flight.

Frequently Asked Questions (FAQ’s) For Aircraft Pneudraulics Repairer

What are the essential skills for an Aircraft Pneudraulics Repairer?

Essential skills for an Aircraft Pneudraulics Repairer include a deep understanding of aircraft pneumatic and hydraulic systems, proficiency in troubleshooting and diagnosing system malfunctions, and expertise in leak detection and repair techniques. Additionally, familiarity with industry regulations, safety protocols, and quality control measures is crucial.

What are the typical job responsibilities of an Aircraft Pneudraulics Repairer?

Aircraft Pneudraulics Repairers are responsible for maintaining, inspecting, and repairing pneumatic and hydraulic systems on aircraft. This includes troubleshooting and diagnosing system malfunctions, replacing and installing components, and performing leak detection and repairs. They also ensure compliance with industry regulations and safety protocols.

What qualifications are needed to become an Aircraft Pneudraulics Repairer?

Minimum qualifications typically include a high school diploma or equivalent and specialized training in aircraft maintenance and repair. Certification from an accredited aviation maintenance program or military experience in aircraft pneudraulics is often preferred by employers.

What industries hire Aircraft Pneudraulics Repairers?

Aircraft Pneudraulics Repairers are primarily employed in the aviation industry, working for airlines, aircraft manufacturers, maintenance, repair, and overhaul (MRO) facilities, and government agencies involved in aircraft operations and maintenance.

What is the job outlook for Aircraft Pneudraulics Repairers?

The job outlook for Aircraft Pneudraulics Repairers is expected to be positive in the coming years due to the increasing demand for qualified aircraft maintenance technicians. The growth in air travel and the aging of aircraft fleets will drive the need for skilled professionals to maintain and repair aircraft systems.

Can an Aircraft Pneudraulics Repairer advance their career?

Yes, Aircraft Pneudraulics Repairers can advance their career by gaining additional experience and qualifications. They can move into supervisory or management roles within the aviation industry, specialize in a particular area of aircraft maintenance, or pursue further education to enhance their technical skills.