Are you a seasoned Greaser seeking a new career path? Discover our professionally built Greaser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

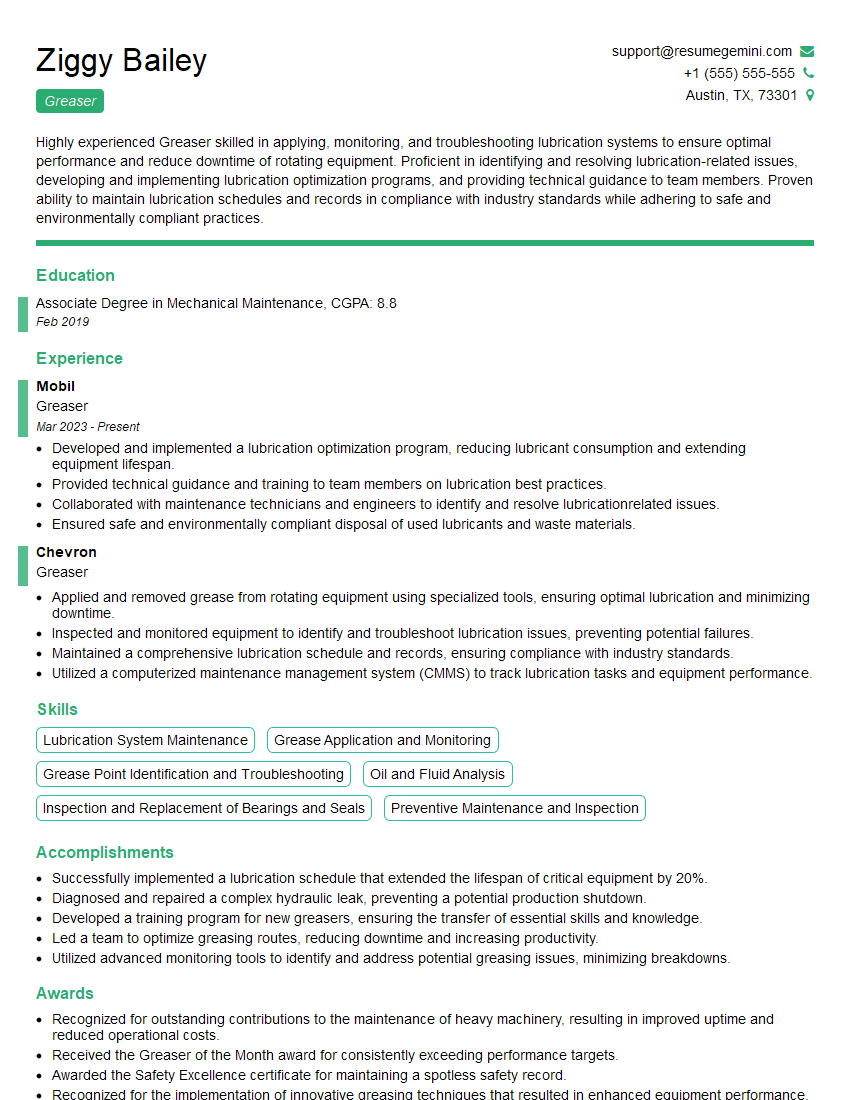

Ziggy Bailey

Greaser

Summary

Highly experienced Greaser skilled in applying, monitoring, and troubleshooting lubrication systems to ensure optimal performance and reduce downtime of rotating equipment. Proficient in identifying and resolving lubrication-related issues, developing and implementing lubrication optimization programs, and providing technical guidance to team members. Proven ability to maintain lubrication schedules and records in compliance with industry standards while adhering to safe and environmentally compliant practices.

Education

Associate Degree in Mechanical Maintenance

February 2019

Skills

- Lubrication System Maintenance

- Grease Application and Monitoring

- Grease Point Identification and Troubleshooting

- Oil and Fluid Analysis

- Inspection and Replacement of Bearings and Seals

- Preventive Maintenance and Inspection

Work Experience

Greaser

- Developed and implemented a lubrication optimization program, reducing lubricant consumption and extending equipment lifespan.

- Provided technical guidance and training to team members on lubrication best practices.

- Collaborated with maintenance technicians and engineers to identify and resolve lubricationrelated issues.

- Ensured safe and environmentally compliant disposal of used lubricants and waste materials.

Greaser

- Applied and removed grease from rotating equipment using specialized tools, ensuring optimal lubrication and minimizing downtime.

- Inspected and monitored equipment to identify and troubleshoot lubrication issues, preventing potential failures.

- Maintained a comprehensive lubrication schedule and records, ensuring compliance with industry standards.

- Utilized a computerized maintenance management system (CMMS) to track lubrication tasks and equipment performance.

Accomplishments

- Successfully implemented a lubrication schedule that extended the lifespan of critical equipment by 20%.

- Diagnosed and repaired a complex hydraulic leak, preventing a potential production shutdown.

- Developed a training program for new greasers, ensuring the transfer of essential skills and knowledge.

- Led a team to optimize greasing routes, reducing downtime and increasing productivity.

- Utilized advanced monitoring tools to identify and address potential greasing issues, minimizing breakdowns.

Awards

- Recognized for outstanding contributions to the maintenance of heavy machinery, resulting in improved uptime and reduced operational costs.

- Received the Greaser of the Month award for consistently exceeding performance targets.

- Awarded the Safety Excellence certificate for maintaining a spotless safety record.

- Recognized for the implementation of innovative greasing techniques that resulted in enhanced equipment performance.

Certificates

- Lubrication Excellence Certification (LEC)

- Machinery Lubrication Technician (MLT)

- Certified Maintenance and Reliability Professional (CMRP)

- Certified Lubrication Specialist (CLS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Greaser

- Quantify your accomplishments: Use specific numbers and metrics to demonstrate the impact of your work.

- Highlight your troubleshooting skills: Emphasize your ability to identify and resolve lubrication-related issues.

- Showcase your knowledge of lubrication systems: Describe your expertise in different types of lubrication systems and their applications.

- Emphasize your commitment to safety and environmental compliance: Highlight your adherence to industry standards and best practices.

Essential Experience Highlights for a Strong Greaser Resume

- Applied and removed grease from rotating equipment using specialized tools, ensuring optimal lubrication and minimizing downtime.

- Inspected and monitored equipment to identify and troubleshoot lubrication issues, preventing potential failures.

- Maintained a comprehensive lubrication schedule and records, ensuring compliance with industry standards.

- Utilized a computerized maintenance management system (CMMS) to track lubrication tasks and equipment performance.

- Developed and implemented a lubrication optimization program, reducing lubricant consumption and extending equipment lifespan.

- Provided technical guidance and training to team members on lubrication best practices.

- Collaborated with maintenance technicians and engineers to identify and resolve lubricationrelated issues.

Frequently Asked Questions (FAQ’s) For Greaser

What are the key responsibilities of a Greaser?

Key responsibilities include applying and removing grease from rotating equipment, inspecting and monitoring equipment for lubrication issues, maintaining lubrication schedules and records, using a CMMS to track lubrication tasks, developing and implementing lubrication optimization programs, providing technical guidance to team members, and collaborating with maintenance technicians and engineers to identify and resolve lubrication-related issues.

What skills are required to be a Greaser?

Required skills include lubrication system maintenance, grease application and monitoring, grease point identification and troubleshooting, oil and fluid analysis, inspection and replacement of bearings and seals, preventive maintenance and inspection, and adherence to safety and environmental compliance regulations.

What is the work environment of a Greaser?

Greasers typically work in industrial or manufacturing environments, where they are responsible for maintaining and lubricating machinery and equipment. They may work indoors or outdoors, and may be exposed to noise, dust, and grease.

What are the career advancement opportunities for a Greaser?

With experience and additional training, Greasers can advance to positions such as Lubrication Technician, Maintenance Technician, or Maintenance Supervisor. They may also specialize in a particular type of lubrication or equipment.

What is the salary range for a Greaser?

The salary range for a Greaser can vary depending on experience, location, and industry. According to Indeed, the average salary for a Greaser in the United States is $24.63 per hour.

What are the job prospects for Greasers?

The job outlook for Greasers is expected to grow 4% from 2021 to 2031, about as fast as the average for all occupations. This growth is expected to be driven by the increasing demand for maintenance and repair services in various industries.