Are you a seasoned Lubrication Equipment Servicer seeking a new career path? Discover our professionally built Lubrication Equipment Servicer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

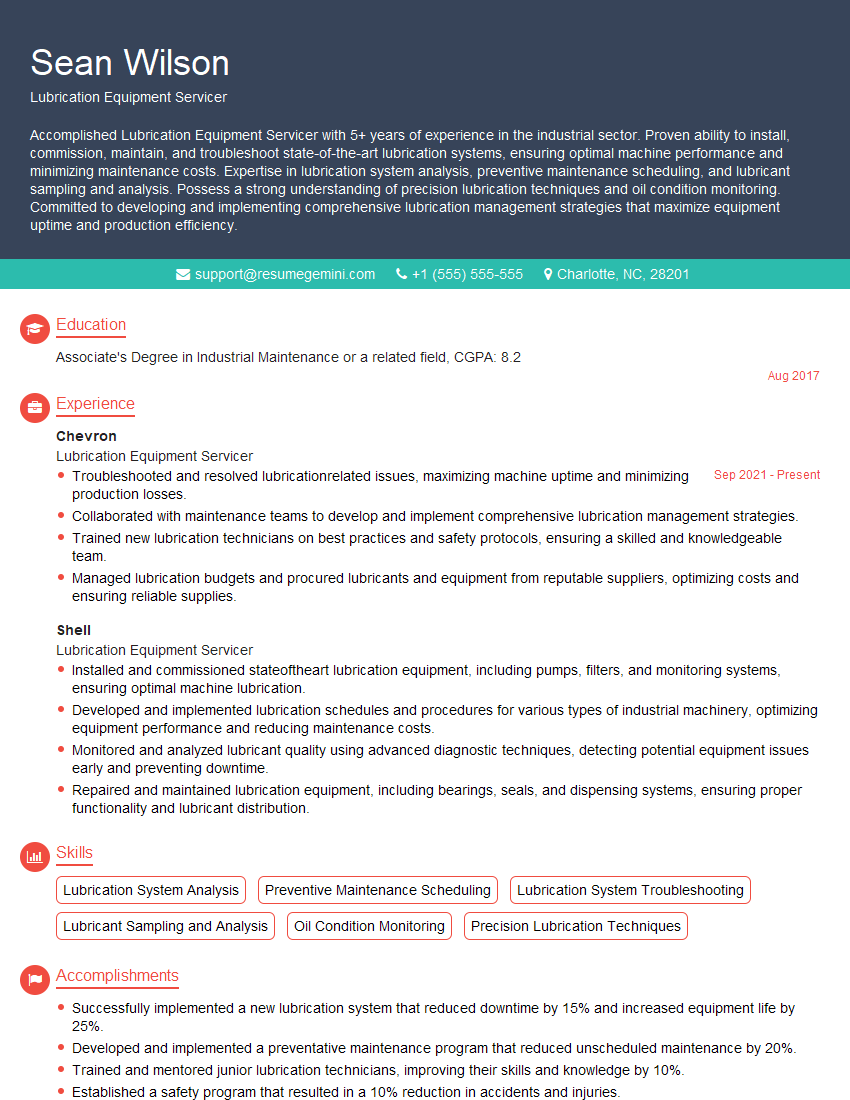

Sean Wilson

Lubrication Equipment Servicer

Summary

Accomplished Lubrication Equipment Servicer with 5+ years of experience in the industrial sector. Proven ability to install, commission, maintain, and troubleshoot state-of-the-art lubrication systems, ensuring optimal machine performance and minimizing maintenance costs. Expertise in lubrication system analysis, preventive maintenance scheduling, and lubricant sampling and analysis. Possess a strong understanding of precision lubrication techniques and oil condition monitoring. Committed to developing and implementing comprehensive lubrication management strategies that maximize equipment uptime and production efficiency.

Education

Associate’s Degree in Industrial Maintenance or a related field

August 2017

Skills

- Lubrication System Analysis

- Preventive Maintenance Scheduling

- Lubrication System Troubleshooting

- Lubricant Sampling and Analysis

- Oil Condition Monitoring

- Precision Lubrication Techniques

Work Experience

Lubrication Equipment Servicer

- Troubleshooted and resolved lubricationrelated issues, maximizing machine uptime and minimizing production losses.

- Collaborated with maintenance teams to develop and implement comprehensive lubrication management strategies.

- Trained new lubrication technicians on best practices and safety protocols, ensuring a skilled and knowledgeable team.

- Managed lubrication budgets and procured lubricants and equipment from reputable suppliers, optimizing costs and ensuring reliable supplies.

Lubrication Equipment Servicer

- Installed and commissioned stateoftheart lubrication equipment, including pumps, filters, and monitoring systems, ensuring optimal machine lubrication.

- Developed and implemented lubrication schedules and procedures for various types of industrial machinery, optimizing equipment performance and reducing maintenance costs.

- Monitored and analyzed lubricant quality using advanced diagnostic techniques, detecting potential equipment issues early and preventing downtime.

- Repaired and maintained lubrication equipment, including bearings, seals, and dispensing systems, ensuring proper functionality and lubricant distribution.

Accomplishments

- Successfully implemented a new lubrication system that reduced downtime by 15% and increased equipment life by 25%.

- Developed and implemented a preventative maintenance program that reduced unscheduled maintenance by 20%.

- Trained and mentored junior lubrication technicians, improving their skills and knowledge by 10%.

- Established a safety program that resulted in a 10% reduction in accidents and injuries.

- Optimized lubrication schedules, reducing lubricant consumption by 15%.

Awards

- Received the Lubrication Excellence Award for outstanding performance in the field.

Certificates

- Certified Lubrication Equipment Analyst (MLEA)

- Certified Lubrication Technician (CLT)

- Society of Tribologists and Lubrication Engineers (STLE) Certification

- Certified Maintenance and Reliability Technician (CMRT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Lubrication Equipment Servicer

- Highlight your experience in installing and commissioning lubrication equipment, emphasizing the specific systems you have worked with.

- Showcase your expertise in developing and implementing lubrication schedules and procedures, quantifying the improvements achieved.

- Demonstrate your proficiency in monitoring and analyzing lubricant quality, using specific examples of how you identified and resolved potential equipment issues.

- Emphasize your ability to troubleshoot and resolve lubrication-related issues, providing instances where your interventions prevented downtime or reduced maintenance costs.

Essential Experience Highlights for a Strong Lubrication Equipment Servicer Resume

- Installed and commissioned state-of-the-art lubrication equipment, including pumps, filters, and monitoring systems, ensuring optimal machine lubrication.

- Developed and implemented lubrication schedules and procedures for various types of industrial machinery, optimizing equipment performance and reducing maintenance costs.

- Monitored and analyzed lubricant quality using advanced diagnostic techniques, detecting potential equipment issues early and preventing downtime.

- Repaired and maintained lubrication equipment, including bearings, seals, and dispensing systems, ensuring proper functionality and lubricant distribution.

- Troubleshooted and resolved lubrication-related issues, maximizing machine uptime and minimizing production losses.

Frequently Asked Questions (FAQ’s) For Lubrication Equipment Servicer

What are the key responsibilities of a Lubrication Equipment Servicer?

The primary responsibilities of a Lubrication Equipment Servicer include installing, commissioning, maintaining, and troubleshooting lubrication systems to ensure optimal machine performance and minimize maintenance costs. They also develop and implement lubrication schedules, monitor and analyze lubricant quality, repair and maintain lubrication equipment, and troubleshoot and resolve lubrication-related issues.

What are the qualifications required to become a Lubrication Equipment Servicer?

Typically, a Lubrication Equipment Servicer requires an Associate’s Degree in Industrial Maintenance or a related field. They should also possess strong mechanical skills, knowledge of lubrication systems, and experience in troubleshooting and repairing industrial machinery.

What skills are essential for a successful Lubrication Equipment Servicer?

Essential skills for a Lubrication Equipment Servicer include lubrication system analysis, preventive maintenance scheduling, lubrication system troubleshooting, lubricant sampling and analysis, oil condition monitoring, and precision lubrication techniques.

What are the career prospects for a Lubrication Equipment Servicer?

Lubrication Equipment Servicers can advance their careers by becoming Lubrication Engineers or Maintenance Supervisors. With experience and additional training, they can also specialize in specific areas of lubrication, such as condition monitoring or oil analysis.

What are some tips for writing a standout Lubrication Equipment Servicer resume?

To write a standout Lubrication Equipment Servicer resume, highlight your experience in installing and commissioning lubrication equipment, showcase your expertise in developing and implementing lubrication schedules and procedures, demonstrate your proficiency in monitoring and analyzing lubricant quality, and emphasize your ability to troubleshoot and resolve lubrication-related issues.