Are you a seasoned Hydraulic Press Servicer seeking a new career path? Discover our professionally built Hydraulic Press Servicer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

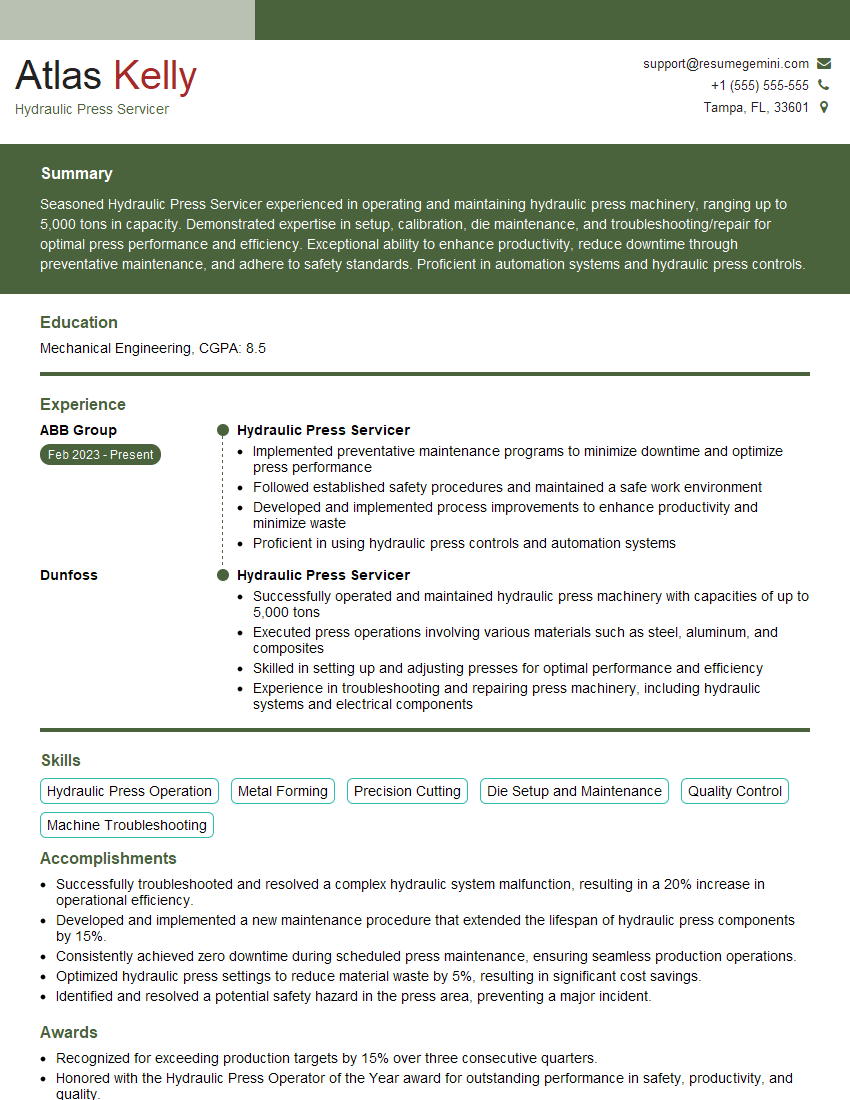

Atlas Kelly

Hydraulic Press Servicer

Summary

Seasoned Hydraulic Press Servicer experienced in operating and maintaining hydraulic press machinery, ranging up to 5,000 tons in capacity. Demonstrated expertise in setup, calibration, die maintenance, and troubleshooting/repair for optimal press performance and efficiency. Exceptional ability to enhance productivity, reduce downtime through preventative maintenance, and adhere to safety standards. Proficient in automation systems and hydraulic press controls.

Education

Mechanical Engineering

January 2019

Skills

- Hydraulic Press Operation

- Metal Forming

- Precision Cutting

- Die Setup and Maintenance

- Quality Control

- Machine Troubleshooting

Work Experience

Hydraulic Press Servicer

- Implemented preventative maintenance programs to minimize downtime and optimize press performance

- Followed established safety procedures and maintained a safe work environment

- Developed and implemented process improvements to enhance productivity and minimize waste

- Proficient in using hydraulic press controls and automation systems

Hydraulic Press Servicer

- Successfully operated and maintained hydraulic press machinery with capacities of up to 5,000 tons

- Executed press operations involving various materials such as steel, aluminum, and composites

- Skilled in setting up and adjusting presses for optimal performance and efficiency

- Experience in troubleshooting and repairing press machinery, including hydraulic systems and electrical components

Accomplishments

- Successfully troubleshooted and resolved a complex hydraulic system malfunction, resulting in a 20% increase in operational efficiency.

- Developed and implemented a new maintenance procedure that extended the lifespan of hydraulic press components by 15%.

- Consistently achieved zero downtime during scheduled press maintenance, ensuring seamless production operations.

- Optimized hydraulic press settings to reduce material waste by 5%, resulting in significant cost savings.

- Identified and resolved a potential safety hazard in the press area, preventing a major incident.

Awards

- Recognized for exceeding production targets by 15% over three consecutive quarters.

- Honored with the Hydraulic Press Operator of the Year award for outstanding performance in safety, productivity, and quality.

- Received a companywide safety award for implementing an innovative safety measure that improved the work environment.

- Recognized by a leading hydraulic equipment manufacturer for providing valuable feedback on product design and development.

Certificates

- Hydraulic Press Operator Certification

- Metal Forming Technician Certification

- Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Hydraulic Press Servicer

- Quantify accomplishments with specific metrics and data whenever possible.

- Highlight your problem-solving skills and ability to identify and resolve issues efficiently.

- Mention industry certifications or specialized training to demonstrate your commitment to professional development.

- Showcase your experience with hydraulic press controls and automation systems.

Essential Experience Highlights for a Strong Hydraulic Press Servicer Resume

- Executed press operations with diverse materials (steel, aluminum, composites) to achieve precise metal forming and cutting.

- Setup, calibrated, and adjusted presses for maximum efficiency and performance.

- Skilled in troubleshooting and repairing hydraulic press machinery, including hydraulic systems and electrical components.

- Implemented proactive maintenance programs to minimize downtime and optimize press performance.

- Adhered to established safety protocols, maintaining a safe work environment.

- Developed and executed process improvements to enhance productivity and efficiency, minimizing waste and optimizing output.

Frequently Asked Questions (FAQ’s) For Hydraulic Press Servicer

What are the primary duties of a Hydraulic Press Servicer?

Hydraulic Press Servicers are responsible for operating, maintaining, and troubleshooting hydraulic press machinery. They also perform setup, calibration, and adjustments to ensure optimal performance and efficiency. Additionally, they implement preventative maintenance programs to minimize downtime and adhere to safety standards.

What skills are essential for a Hydraulic Press Servicer?

Essential skills for a Hydraulic Press Servicer include: hydraulic press operation, metal forming, precision cutting, die setup and maintenance, quality control, machine troubleshooting, and proficiency in hydraulic press controls and automation systems.

What industries employ Hydraulic Press Servicers?

Hydraulic Press Servicers are employed in various industries that utilize hydraulic press machinery, including automotive, aerospace, manufacturing, and metalworking.

What is the average salary for a Hydraulic Press Servicer?

The average salary for a Hydraulic Press Servicer can vary depending on experience, location, and industry. According to Salary.com, the median annual salary for a Hydraulic Press Servicer in the United States is around $45,000.

What are the career advancement opportunities for a Hydraulic Press Servicer?

Hydraulic Press Servicers can advance their careers by gaining experience, obtaining certifications, and developing specialized skills. They can move into supervisory or management roles, or specialize in areas such as machine maintenance or process improvement.

What is the job outlook for Hydraulic Press Servicers?

The job outlook for Hydraulic Press Servicers is expected to be favorable in the coming years. The growing demand for metalworking and manufacturing is expected to drive the need for skilled press operators and servicers.