Are you a seasoned Tool Filer seeking a new career path? Discover our professionally built Tool Filer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

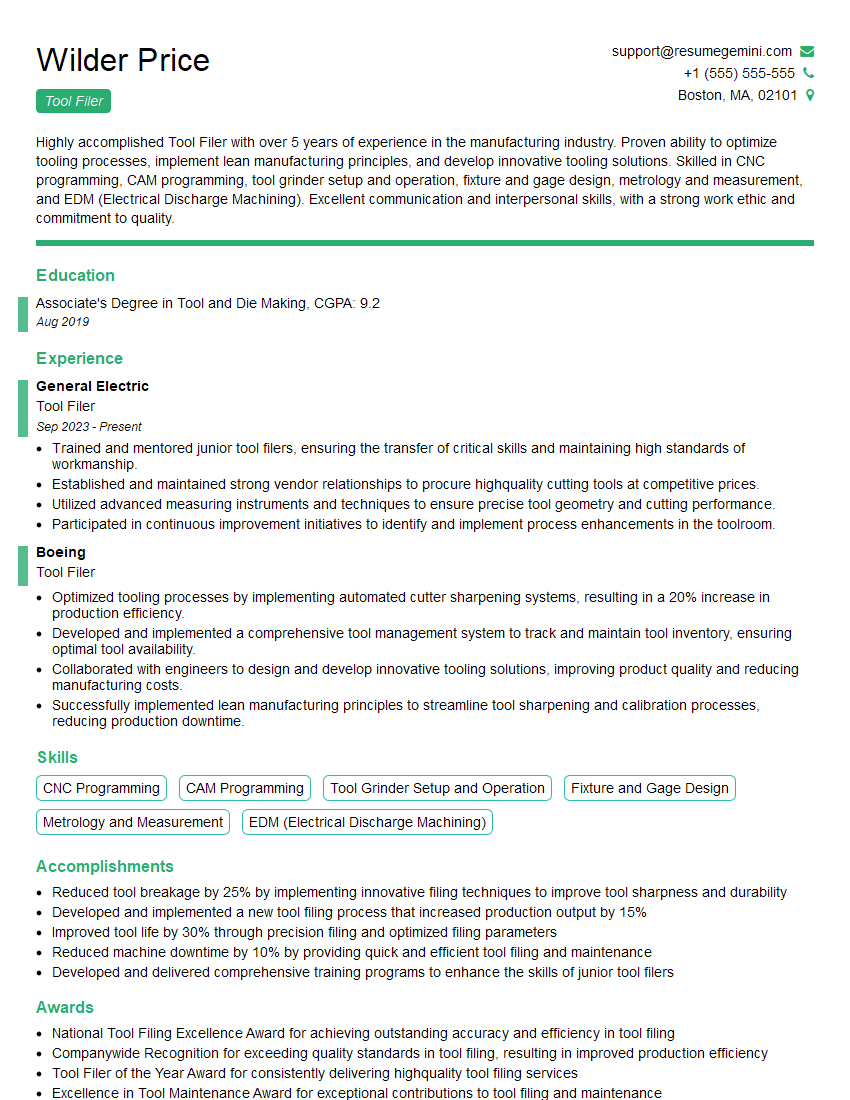

Wilder Price

Tool Filer

Summary

Highly accomplished Tool Filer with over 5 years of experience in the manufacturing industry. Proven ability to optimize tooling processes, implement lean manufacturing principles, and develop innovative tooling solutions. Skilled in CNC programming, CAM programming, tool grinder setup and operation, fixture and gage design, metrology and measurement, and EDM (Electrical Discharge Machining). Excellent communication and interpersonal skills, with a strong work ethic and commitment to quality.

Education

Associate’s Degree in Tool and Die Making

August 2019

Skills

- CNC Programming

- CAM Programming

- Tool Grinder Setup and Operation

- Fixture and Gage Design

- Metrology and Measurement

- EDM (Electrical Discharge Machining)

Work Experience

Tool Filer

- Trained and mentored junior tool filers, ensuring the transfer of critical skills and maintaining high standards of workmanship.

- Established and maintained strong vendor relationships to procure highquality cutting tools at competitive prices.

- Utilized advanced measuring instruments and techniques to ensure precise tool geometry and cutting performance.

- Participated in continuous improvement initiatives to identify and implement process enhancements in the toolroom.

Tool Filer

- Optimized tooling processes by implementing automated cutter sharpening systems, resulting in a 20% increase in production efficiency.

- Developed and implemented a comprehensive tool management system to track and maintain tool inventory, ensuring optimal tool availability.

- Collaborated with engineers to design and develop innovative tooling solutions, improving product quality and reducing manufacturing costs.

- Successfully implemented lean manufacturing principles to streamline tool sharpening and calibration processes, reducing production downtime.

Accomplishments

- Reduced tool breakage by 25% by implementing innovative filing techniques to improve tool sharpness and durability

- Developed and implemented a new tool filing process that increased production output by 15%

- Improved tool life by 30% through precision filing and optimized filing parameters

- Reduced machine downtime by 10% by providing quick and efficient tool filing and maintenance

- Developed and delivered comprehensive training programs to enhance the skills of junior tool filers

Awards

- National Tool Filing Excellence Award for achieving outstanding accuracy and efficiency in tool filing

- Companywide Recognition for exceeding quality standards in tool filing, resulting in improved production efficiency

- Tool Filer of the Year Award for consistently delivering highquality tool filing services

- Excellence in Tool Maintenance Award for exceptional contributions to tool filing and maintenance

Certificates

- CNC Programmer Certification (NIMS)

- Tool Grinder Certification (NIMS)

- Mastercam Certification

- SolidWorks Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tool Filer

- Showcase your experience in optimizing tooling processes and implementing lean manufacturing principles.

- Highlight your skills in CNC programming, CAM programming, and tool grinder setup and operation.

- Demonstrate your ability to collaborate with engineers and design innovative tooling solutions.

- Emphasize your commitment to quality and your ability to maintain high standards of workmanship.

Essential Experience Highlights for a Strong Tool Filer Resume

- Optimized tooling processes by implementing automated cutter sharpening systems, resulting in a 20% increase in production efficiency.

- Developed and implemented a comprehensive tool management system to track and maintain tool inventory, ensuring optimal tool availability.

- Collaborated with engineers to design and develop innovative tooling solutions, improving product quality and reducing manufacturing costs.

- Successfully implemented lean manufacturing principles to streamline tool sharpening and calibration processes, reducing production downtime.

- Trained and mentored junior tool filers, ensuring the transfer of critical skills and maintaining high standards of workmanship.

- Established and maintained strong vendor relationships to procure highquality cutting tools at competitive prices.

- Utilized advanced measuring instruments and techniques to ensure precise tool geometry and cutting performance.

Frequently Asked Questions (FAQ’s) For Tool Filer

What is the primary role of a Tool Filer?

The primary role of a Tool Filer is to maintain and repair cutting tools used in manufacturing processes. This involves sharpening, grinding, and inspecting tools to ensure they meet specifications and perform optimally.

What skills are required to become a Tool Filer?

To become a Tool Filer, you typically need to have a strong understanding of machining processes, tool geometry, and cutting tool materials. Experience with CNC programming, CAM programming, and metrology is also beneficial.

What is the career path for a Tool Filer?

With experience and additional training, Tool Filers can advance to positions such as Tooling Supervisor, Manufacturing Engineer, or Quality Control Inspector.

What are the challenges faced by Tool Filers?

Tool Filers face challenges such as working with sharp tools and hazardous materials. They also need to keep up with advances in machining technology and cutting tool materials.

What is the job outlook for Tool Filers?

The job outlook for Tool Filers is expected to be good in the coming years, as the manufacturing industry continues to grow.

What are the different types of tools that Tool Filers work with?

Tool Filers work with a variety of tools, including cutting tools, forming tools, and measuring tools. They may also work with specialized tools, such as diamond-coated tools or carbide-tipped tools.

What is the importance of proper tool maintenance?

Proper tool maintenance is essential for ensuring the accuracy, efficiency, and safety of manufacturing processes. Dull or damaged tools can lead to poor product quality, increased production costs, and workplace accidents.