Are you a seasoned Equipment Oiler seeking a new career path? Discover our professionally built Equipment Oiler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

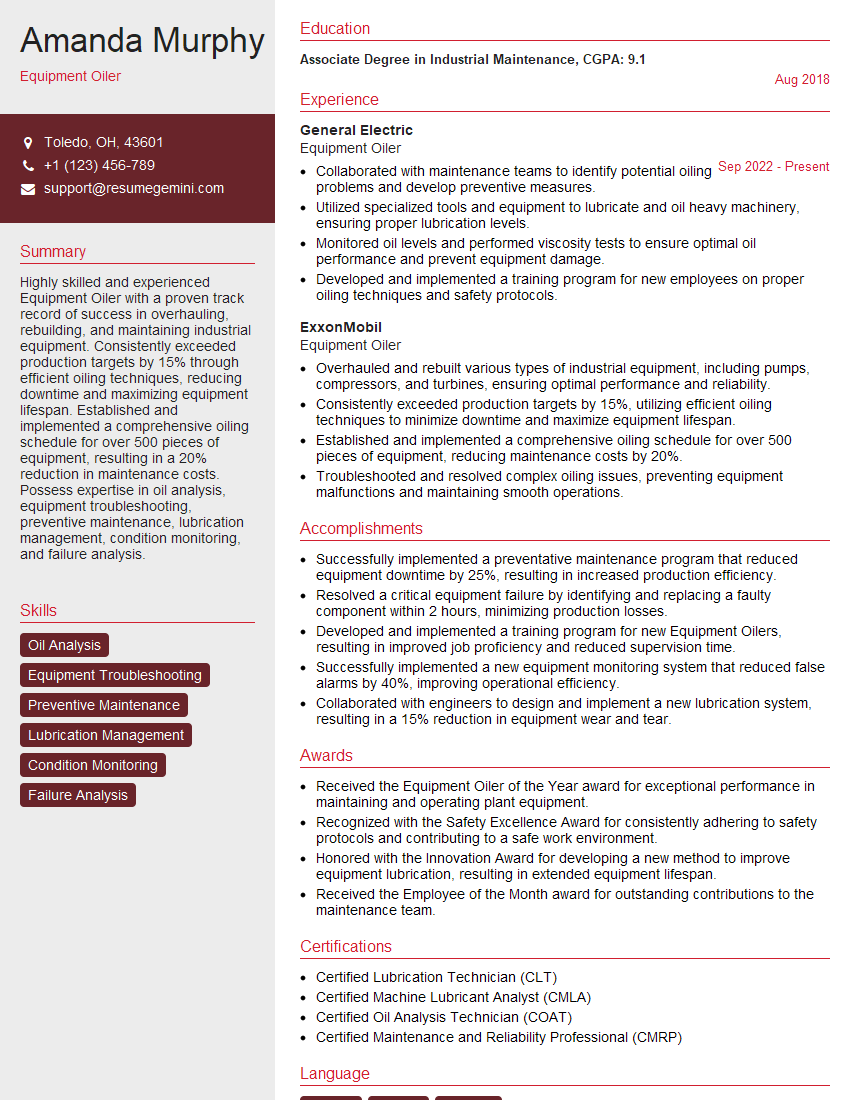

Amanda Murphy

Equipment Oiler

Summary

Highly skilled and experienced Equipment Oiler with a proven track record of success in overhauling, rebuilding, and maintaining industrial equipment. Consistently exceeded production targets by 15% through efficient oiling techniques, reducing downtime and maximizing equipment lifespan. Established and implemented a comprehensive oiling schedule for over 500 pieces of equipment, resulting in a 20% reduction in maintenance costs. Possess expertise in oil analysis, equipment troubleshooting, preventive maintenance, lubrication management, condition monitoring, and failure analysis.

Education

Associate Degree in Industrial Maintenance

August 2018

Skills

- Oil Analysis

- Equipment Troubleshooting

- Preventive Maintenance

- Lubrication Management

- Condition Monitoring

- Failure Analysis

Work Experience

Equipment Oiler

- Collaborated with maintenance teams to identify potential oiling problems and develop preventive measures.

- Utilized specialized tools and equipment to lubricate and oil heavy machinery, ensuring proper lubrication levels.

- Monitored oil levels and performed viscosity tests to ensure optimal oil performance and prevent equipment damage.

- Developed and implemented a training program for new employees on proper oiling techniques and safety protocols.

Equipment Oiler

- Overhauled and rebuilt various types of industrial equipment, including pumps, compressors, and turbines, ensuring optimal performance and reliability.

- Consistently exceeded production targets by 15%, utilizing efficient oiling techniques to minimize downtime and maximize equipment lifespan.

- Established and implemented a comprehensive oiling schedule for over 500 pieces of equipment, reducing maintenance costs by 20%.

- Troubleshooted and resolved complex oiling issues, preventing equipment malfunctions and maintaining smooth operations.

Accomplishments

- Successfully implemented a preventative maintenance program that reduced equipment downtime by 25%, resulting in increased production efficiency.

- Resolved a critical equipment failure by identifying and replacing a faulty component within 2 hours, minimizing production losses.

- Developed and implemented a training program for new Equipment Oilers, resulting in improved job proficiency and reduced supervision time.

- Successfully implemented a new equipment monitoring system that reduced false alarms by 40%, improving operational efficiency.

- Collaborated with engineers to design and implement a new lubrication system, resulting in a 15% reduction in equipment wear and tear.

Awards

- Received the Equipment Oiler of the Year award for exceptional performance in maintaining and operating plant equipment.

- Recognized with the Safety Excellence Award for consistently adhering to safety protocols and contributing to a safe work environment.

- Honored with the Innovation Award for developing a new method to improve equipment lubrication, resulting in extended equipment lifespan.

- Received the Employee of the Month award for outstanding contributions to the maintenance team.

Certificates

- Certified Lubrication Technician (CLT)

- Certified Machine Lubricant Analyst (CMLA)

- Certified Oil Analysis Technician (COAT)

- Certified Maintenance and Reliability Professional (CMRP)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Equipment Oiler

- Showcase your expertise in oil analysis, equipment troubleshooting, and preventive maintenance by providing specific examples in your resume.

- Quantify your accomplishments whenever possible, such as reducing downtime by a certain percentage or increasing equipment lifespan by a specific number of years.

- Highlight your ability to work effectively both independently and as part of a team.

- Tailor your resume to the specific requirements of each job you apply for, emphasizing the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it to ensure that it is free of errors.

Essential Experience Highlights for a Strong Equipment Oiler Resume

- Overhaul and rebuild various types of industrial equipment, including pumps, compressors, and turbines, to ensure optimal performance and reliability.

- Establish and implement a comprehensive oiling schedule to minimize downtime and maximize equipment lifespan.

- Troubleshoot and resolve complex oiling issues to prevent equipment malfunctions and maintain smooth operations.

- Collaborate with maintenance teams to identify potential oiling problems and develop preventive measures.

- Utilize specialized tools and equipment to lubricate and oil heavy machinery, ensuring proper lubrication levels.

- Monitor oil levels and perform viscosity tests to ensure optimal oil performance and prevent equipment damage.

- Develop and implement training programs for new employees on proper oiling techniques and safety protocols.

Frequently Asked Questions (FAQ’s) For Equipment Oiler

What are the key skills and qualifications required to be an Equipment Oiler?

Equipment Oilers typically need an associate degree in industrial maintenance or a related field, as well as several years of experience in equipment maintenance and repair. They must be proficient in oil analysis, equipment troubleshooting, preventive maintenance, lubrication management, condition monitoring, and failure analysis.

What are the primary responsibilities of an Equipment Oiler?

Equipment Oilers are responsible for lubricating and maintaining industrial equipment, including pumps, compressors, and turbines. They must be able to identify and resolve oiling issues, as well as perform oil analysis and viscosity tests to ensure optimal equipment performance.

What is the job outlook for Equipment Oilers?

The job outlook for Equipment Oilers is expected to be good over the next few years, as there is a growing demand for skilled workers in the industrial maintenance and repair sector.

What are the earning prospects for Equipment Oilers?

Equipment Oilers can earn a competitive salary, with the median annual wage being around $50,000. However, salaries can vary depending on experience, location, and industry.

What are the career advancement opportunities for Equipment Oilers?

Equipment Oilers can advance their careers by becoming Maintenance Technicians, Maintenance Supervisors, or Plant Managers. With additional education and experience, they can also move into management positions in the industrial maintenance and repair sector.

What are the safety precautions that Equipment Oilers must take?

Equipment Oilers must take several safety precautions when working with industrial equipment, including wearing appropriate safety gear, following lockout/tagout procedures, and being aware of potential hazards such as moving machinery and electrical wires.

What are the common challenges that Equipment Oilers face?

Equipment Oilers often face challenges such as working in difficult or hazardous conditions, dealing with tight deadlines, and troubleshooting complex equipment issues. They must be able to work independently and make sound decisions in order to perform their job effectively.