Are you a seasoned Rubber and Plastics Worker seeking a new career path? Discover our professionally built Rubber and Plastics Worker Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

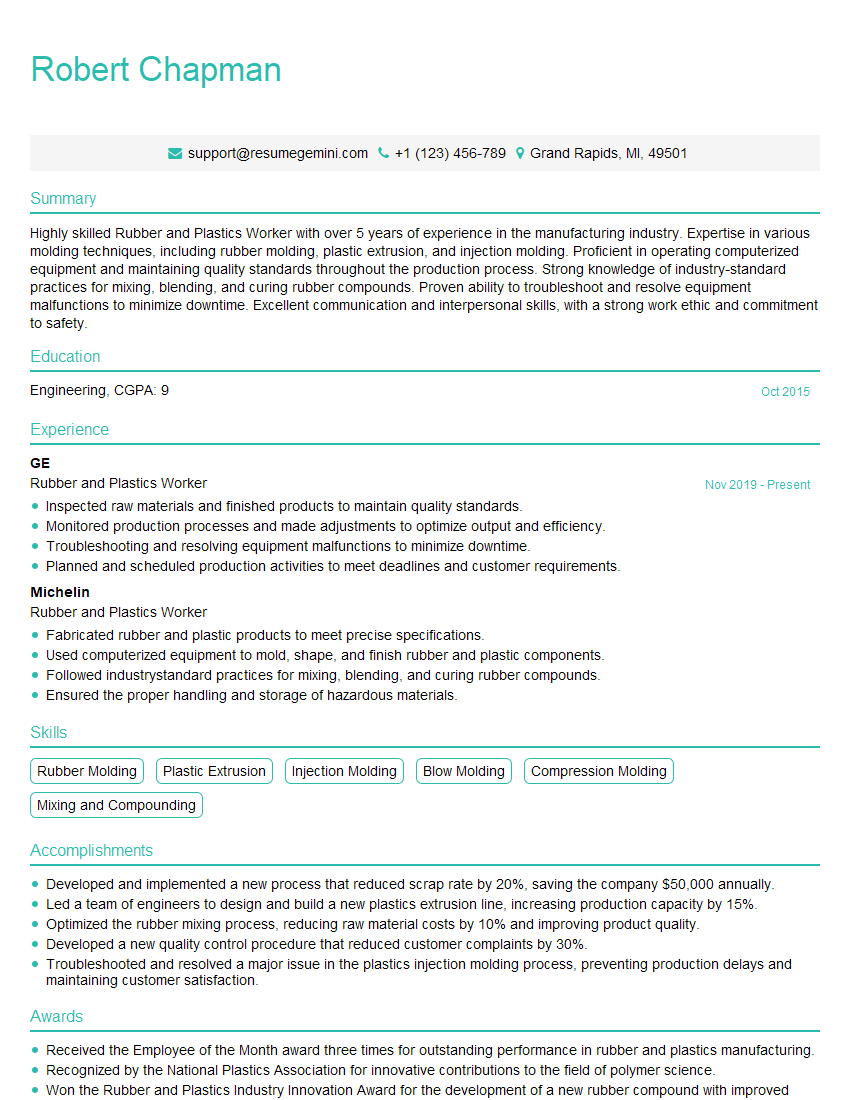

Robert Chapman

Rubber and Plastics Worker

Summary

Highly skilled Rubber and Plastics Worker with over 5 years of experience in the manufacturing industry. Expertise in various molding techniques, including rubber molding, plastic extrusion, and injection molding. Proficient in operating computerized equipment and maintaining quality standards throughout the production process. Strong knowledge of industry-standard practices for mixing, blending, and curing rubber compounds. Proven ability to troubleshoot and resolve equipment malfunctions to minimize downtime. Excellent communication and interpersonal skills, with a strong work ethic and commitment to safety.

Education

Engineering

October 2015

Skills

- Rubber Molding

- Plastic Extrusion

- Injection Molding

- Blow Molding

- Compression Molding

- Mixing and Compounding

Work Experience

Rubber and Plastics Worker

- Inspected raw materials and finished products to maintain quality standards.

- Monitored production processes and made adjustments to optimize output and efficiency.

- Troubleshooting and resolving equipment malfunctions to minimize downtime.

- Planned and scheduled production activities to meet deadlines and customer requirements.

Rubber and Plastics Worker

- Fabricated rubber and plastic products to meet precise specifications.

- Used computerized equipment to mold, shape, and finish rubber and plastic components.

- Followed industrystandard practices for mixing, blending, and curing rubber compounds.

- Ensured the proper handling and storage of hazardous materials.

Accomplishments

- Developed and implemented a new process that reduced scrap rate by 20%, saving the company $50,000 annually.

- Led a team of engineers to design and build a new plastics extrusion line, increasing production capacity by 15%.

- Optimized the rubber mixing process, reducing raw material costs by 10% and improving product quality.

- Developed a new quality control procedure that reduced customer complaints by 30%.

- Troubleshooted and resolved a major issue in the plastics injection molding process, preventing production delays and maintaining customer satisfaction.

Awards

- Received the Employee of the Month award three times for outstanding performance in rubber and plastics manufacturing.

- Recognized by the National Plastics Association for innovative contributions to the field of polymer science.

- Won the Rubber and Plastics Industry Innovation Award for the development of a new rubber compound with improved durability and flexibility.

- Received the Safety Excellence Award for consistently maintaining a safe and accidentfree work environment.

Certificates

- Certified Rubber Processor

- Certified Plastic Processor

- ISO 9001 Quality Management System

- OSHA Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rubber and Plastics Worker

- Highlight your experience in the rubber and plastics industry, including any specific molding techniques or equipment you have worked with.

- Showcase your knowledge of industry-standard practices and your commitment to quality.

- Demonstrate your problem-solving skills and ability to troubleshoot and resolve equipment malfunctions.

- Emphasize your communication and interpersonal skills, as well as your commitment to safety.

- Review the job description and tailor your resume to highlight the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Rubber and Plastics Worker Resume

- Collaborated with engineers and designers to develop and manufacture custom rubber and plastic components.

- Followed industry-standard practices for mixing, blending, and curing rubber compounds.

- Utilized advanced manufacturing techniques, such as CAD/CAM and CNC machining, to create complex rubber and plastic products.

- Inspected raw materials and finished products to maintain quality standards.

- Monitored production processes and made adjustments to optimize output and efficiency.

- Planned and scheduled production activities to meet deadlines and customer requirements.

Frequently Asked Questions (FAQ’s) For Rubber and Plastics Worker

What are the different types of molding techniques used in the rubber and plastics industry?

Some of the most common molding techniques used in the rubber and plastics industry include rubber molding, plastic extrusion, injection molding, blow molding, and compression molding.

What are the important safety considerations for rubber and plastics workers?

Rubber and plastics workers should always wear appropriate personal protective equipment (PPE), such as gloves, masks, and safety glasses. They should also be aware of the potential hazards associated with working with hazardous materials, such as rubber dust and plastic fumes.

What are the career prospects for rubber and plastics workers?

Rubber and plastics workers can advance their careers by gaining experience in different areas of the industry, such as product development, manufacturing, or quality control. They can also pursue further education, such as a degree in engineering or business, to qualify for management or supervisory positions.

What are the key skills and qualifications for rubber and plastics workers?

Rubber and plastics workers should have a strong understanding of the rubber and plastics industry, including the different types of molding techniques and equipment. They should also be proficient in reading blueprints and technical drawings, and have good communication and interpersonal skills.

What are the different types of work environments for rubber and plastics workers?

Rubber and plastics workers may work in a variety of work environments, including factories, workshops, and laboratories. They may also work outdoors, depending on the nature of their job.

What are the physical demands of being a rubber and plastics worker?

Rubber and plastics workers may be required to stand for long periods of time, lift heavy objects, and work in hot or humid environments.