Are you a seasoned Machine Installer seeking a new career path? Discover our professionally built Machine Installer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

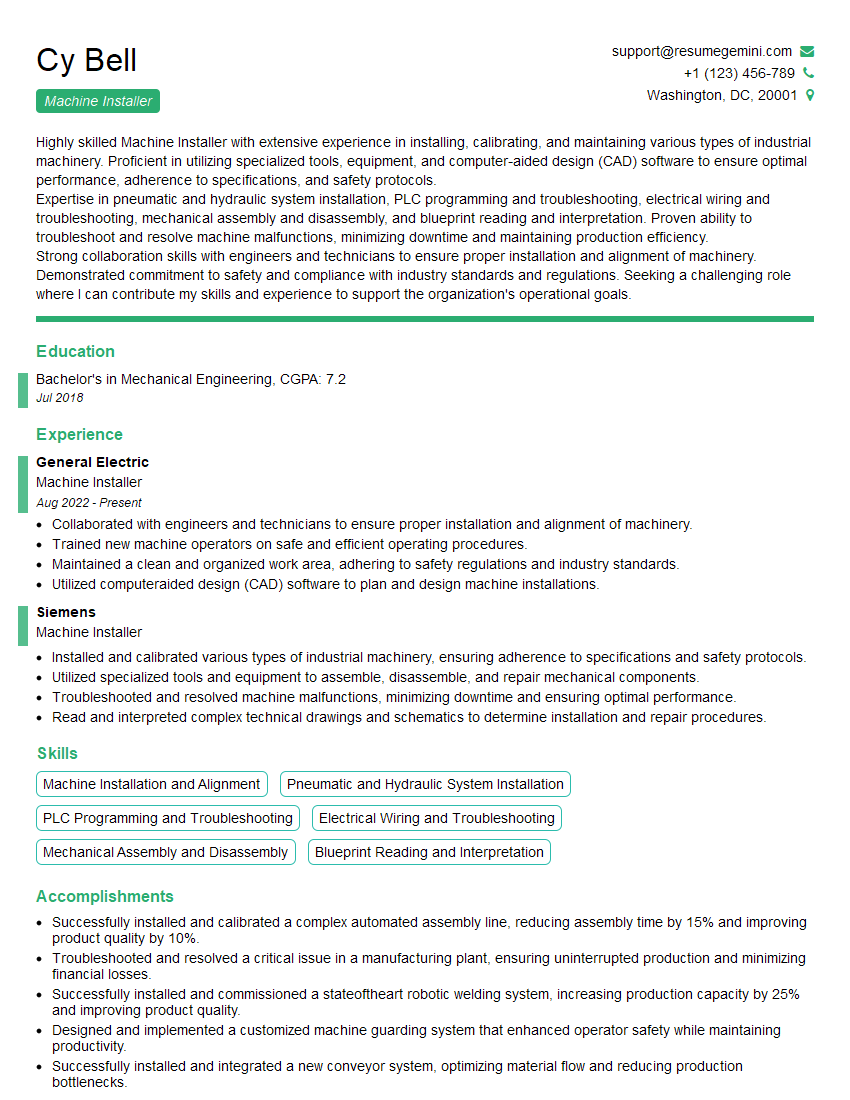

Cy Bell

Machine Installer

Summary

Highly skilled Machine Installer with extensive experience in installing, calibrating, and maintaining various types of industrial machinery. Proficient in utilizing specialized tools, equipment, and computer-aided design (CAD) software to ensure optimal performance, adherence to specifications, and safety protocols.

Expertise in pneumatic and hydraulic system installation, PLC programming and troubleshooting, electrical wiring and troubleshooting, mechanical assembly and disassembly, and blueprint reading and interpretation. Proven ability to troubleshoot and resolve machine malfunctions, minimizing downtime and maintaining production efficiency.

Strong collaboration skills with engineers and technicians to ensure proper installation and alignment of machinery. Demonstrated commitment to safety and compliance with industry standards and regulations. Seeking a challenging role where I can contribute my skills and experience to support the organization’s operational goals.

Education

Bachelor’s in Mechanical Engineering

July 2018

Skills

- Machine Installation and Alignment

- Pneumatic and Hydraulic System Installation

- PLC Programming and Troubleshooting

- Electrical Wiring and Troubleshooting

- Mechanical Assembly and Disassembly

- Blueprint Reading and Interpretation

Work Experience

Machine Installer

- Collaborated with engineers and technicians to ensure proper installation and alignment of machinery.

- Trained new machine operators on safe and efficient operating procedures.

- Maintained a clean and organized work area, adhering to safety regulations and industry standards.

- Utilized computeraided design (CAD) software to plan and design machine installations.

Machine Installer

- Installed and calibrated various types of industrial machinery, ensuring adherence to specifications and safety protocols.

- Utilized specialized tools and equipment to assemble, disassemble, and repair mechanical components.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and ensuring optimal performance.

- Read and interpreted complex technical drawings and schematics to determine installation and repair procedures.

Accomplishments

- Successfully installed and calibrated a complex automated assembly line, reducing assembly time by 15% and improving product quality by 10%.

- Troubleshooted and resolved a critical issue in a manufacturing plant, ensuring uninterrupted production and minimizing financial losses.

- Successfully installed and commissioned a stateoftheart robotic welding system, increasing production capacity by 25% and improving product quality.

- Designed and implemented a customized machine guarding system that enhanced operator safety while maintaining productivity.

- Successfully installed and integrated a new conveyor system, optimizing material flow and reducing production bottlenecks.

Awards

- Received Installer of the Quarter award for exceptional precision and efficiency in machine installation, consistently exceeding performance targets.

- Recognized for developing an innovative mounting system that significantly improved machine stability and reduced downtime by 20%.

- Awarded Safety Superstar for maintaining an impeccable safety record and implementing proactive safety measures in the workplace.

- Received a certificate of appreciation for providing expert technical assistance and training to junior machine installers.

Certificates

- Certified Machine Installer (CMI)

- Certified Machine Technician (CMT)

- OSHA 10-Hour Safety Training

- NFPA 70E Electrical Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machine Installer

- Highlight your technical skills and experience in installing, calibrating, and repairing industrial machinery.

- Provide specific examples of your troubleshooting and problem-solving abilities.

- Emphasize your knowledge of safety protocols and industry standards.

- Showcase your ability to collaborate with engineers and technicians in a team environment.

Essential Experience Highlights for a Strong Machine Installer Resume

- Installed and calibrated various types of industrial machinery, ensuring adherence to specifications and safety protocols.

- Utilized specialized tools and equipment to assemble, disassemble, and repair mechanical components.

- Troubleshooted and resolved machine malfunctions, minimizing downtime and ensuring optimal performance.

- Read and interpreted complex technical drawings and schematics to determine installation and repair procedures.

- Collaborated with engineers and technicians to ensure proper installation and alignment of machinery.

- Trained new machine operators on safe and efficient operating procedures.

- Utilized computer-aided design (CAD) software to plan and design machine installations.

Frequently Asked Questions (FAQ’s) For Machine Installer

What are the key skills and qualifications required for a Machine Installer?

Machine Installers typically require a high school diploma or equivalent, along with specialized training in machine installation and maintenance. Key skills include proficiency in using hand and power tools, knowledge of electrical and mechanical systems, and the ability to read and interpret technical drawings.

What are the job responsibilities of a Machine Installer?

Machine Installers are responsible for installing, calibrating, maintaining, and repairing industrial machinery. They work closely with engineers and technicians to ensure that machines are properly installed and aligned, and that they meet safety and performance standards.

What are the career prospects for Machine Installers?

Machine Installers can advance their careers by gaining experience and developing specialized skills. They can become supervisors, project managers, or technical trainers. With additional education and training, they can also move into engineering or management roles.

What is the work environment of a Machine Installer like?

Machine Installers typically work in industrial settings, such as factories, warehouses, and construction sites. They may work indoors or outdoors, and they may be exposed to noise, dust, and other hazards.

What are the safety precautions that Machine Installers must follow?

Machine Installers must follow all safety precautions when working with machinery. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and earplugs. They must also be aware of the potential hazards associated with working with electricity and moving machinery.

What is the salary range for Machine Installers?

The salary range for Machine Installers varies depending on their experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Machine Installers was $49,520 in May 2021.

What are the benefits of working as a Machine Installer?

Machine Installers enjoy a number of benefits, including job security, opportunities for advancement, and competitive salaries. They also have the satisfaction of working with cutting-edge technology and contributing to the success of their organization.