Are you a seasoned Line Lead seeking a new career path? Discover our professionally built Line Lead Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

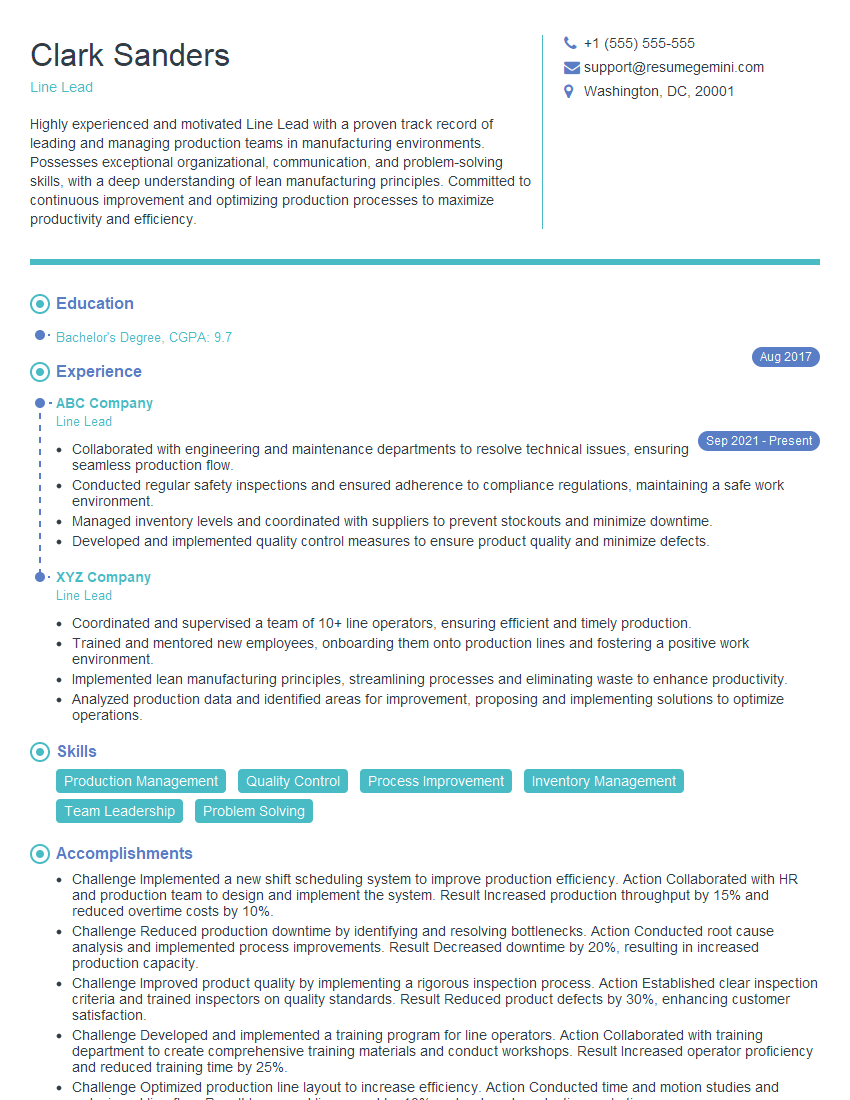

Clark Sanders

Line Lead

Summary

Highly experienced and motivated Line Lead with a proven track record of leading and managing production teams in manufacturing environments. Possesses exceptional organizational, communication, and problem-solving skills, with a deep understanding of lean manufacturing principles. Committed to continuous improvement and optimizing production processes to maximize productivity and efficiency.

Education

Bachelor’s Degree

August 2017

Skills

- Production Management

- Quality Control

- Process Improvement

- Inventory Management

- Team Leadership

- Problem Solving

Work Experience

Line Lead

- Collaborated with engineering and maintenance departments to resolve technical issues, ensuring seamless production flow.

- Conducted regular safety inspections and ensured adherence to compliance regulations, maintaining a safe work environment.

- Managed inventory levels and coordinated with suppliers to prevent stockouts and minimize downtime.

- Developed and implemented quality control measures to ensure product quality and minimize defects.

Line Lead

- Coordinated and supervised a team of 10+ line operators, ensuring efficient and timely production.

- Trained and mentored new employees, onboarding them onto production lines and fostering a positive work environment.

- Implemented lean manufacturing principles, streamlining processes and eliminating waste to enhance productivity.

- Analyzed production data and identified areas for improvement, proposing and implementing solutions to optimize operations.

Accomplishments

- Challenge Implemented a new shift scheduling system to improve production efficiency. Action Collaborated with HR and production team to design and implement the system. Result Increased production throughput by 15% and reduced overtime costs by 10%.

- Challenge Reduced production downtime by identifying and resolving bottlenecks. Action Conducted root cause analysis and implemented process improvements. Result Decreased downtime by 20%, resulting in increased production capacity.

- Challenge Improved product quality by implementing a rigorous inspection process. Action Established clear inspection criteria and trained inspectors on quality standards. Result Reduced product defects by 30%, enhancing customer satisfaction.

- Challenge Developed and implemented a training program for line operators. Action Collaborated with training department to create comprehensive training materials and conduct workshops. Result Increased operator proficiency and reduced training time by 25%.

- Challenge Optimized production line layout to increase efficiency. Action Conducted time and motion studies and redesigned line flow. Result Increased line speed by 10% and reduced production cycle time.

Awards

- Received Line Lead of the Year award for exceptional performance in production optimization and team management.

- Recognized with a Team Excellence Award for leading a team that consistently exceeded production targets.

- Awarded Safety Champion recognition for implementing innovative safety measures and promoting a safe work environment.

- Received Line Lead of the Quarter Award for outstanding leadership and contributions to team performance.

Certificates

- Certified Production Manager (CPM)

- Certified Quality Inspector (CQI)

- HACCP Manager

- Food Safety Certified Manager (FSC)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Line Lead

- Highlight your experience in leading and managing production teams, emphasizing your ability to motivate and empower employees.

- Quantify your accomplishments using specific metrics to demonstrate the impact of your contributions.

- Showcase your knowledge of lean manufacturing principles and how you have applied them to improve processes and increase efficiency.

- Emphasize your problem-solving and analytical skills, providing examples of how you have identified and resolved issues to optimize production.

- Proofread your resume carefully for any errors or inconsistencies.

Essential Experience Highlights for a Strong Line Lead Resume

- Coordinated and supervised teams of production line operators, ensuring timely and efficient completion of production goals.

- Trained and mentored new hires, providing guidance and support to foster a positive and productive work environment.

- Implemented lean manufacturing techniques, streamlining processes and eliminating waste to enhance productivity and reduce costs.

- Analyzed production data, identified areas for improvement, and proposed and implemented solutions to optimize operations.

- Collaborated closely with engineering and maintenance departments to resolve technical issues and ensure seamless production flow.

- Conducted regular safety inspections and ensured adherence to compliance regulations, maintaining a safe and healthy work environment.

- Managed inventory levels and coordinated with suppliers to prevent stockouts and minimize downtime.

Frequently Asked Questions (FAQ’s) For Line Lead

What are the key responsibilities of a Line Lead?

Line Leads are responsible for leading and supervising production teams, ensuring efficient and timely production, training and mentoring new employees, implementing lean manufacturing principles, analyzing production data, collaborating with other departments, and maintaining a safe and compliant work environment.

What are the qualifications required to be a Line Lead?

Typically, a bachelor’s degree in a relevant field is required, along with several years of experience in production management or a related area. Strong leadership, communication, and problem-solving skills are also essential.

What are the career prospects for Line Leads?

Line Leads can advance to management positions within manufacturing, such as Production Manager or Plant Manager. They may also move into roles in quality control, process improvement, or supply chain management.

What are the challenges faced by Line Leads?

Line Leads face challenges such as managing diverse teams, meeting production targets, ensuring product quality, and maintaining a safe and efficient work environment. They must also be able to adapt to changing market conditions and technological advancements.

What are the key skills required for a Line Lead?

Key skills for a Line Lead include leadership, communication, problem-solving, analytical thinking, and knowledge of lean manufacturing principles. They must also be proficient in Microsoft Office Suite and have a strong understanding of production processes.

What is the work environment like for a Line Lead?

Line Leads typically work in manufacturing facilities, overseeing production lines and managing teams. The work environment can be fast-paced and demanding, requiring the ability to make quick decisions and handle multiple tasks simultaneously.

What are the benefits of being a Line Lead?

Benefits of being a Line Lead include competitive salaries, opportunities for career advancement, and the satisfaction of leading and developing teams while contributing to the success of a manufacturing organization.