Are you a seasoned Industrial Maintenance Repairer seeking a new career path? Discover our professionally built Industrial Maintenance Repairer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

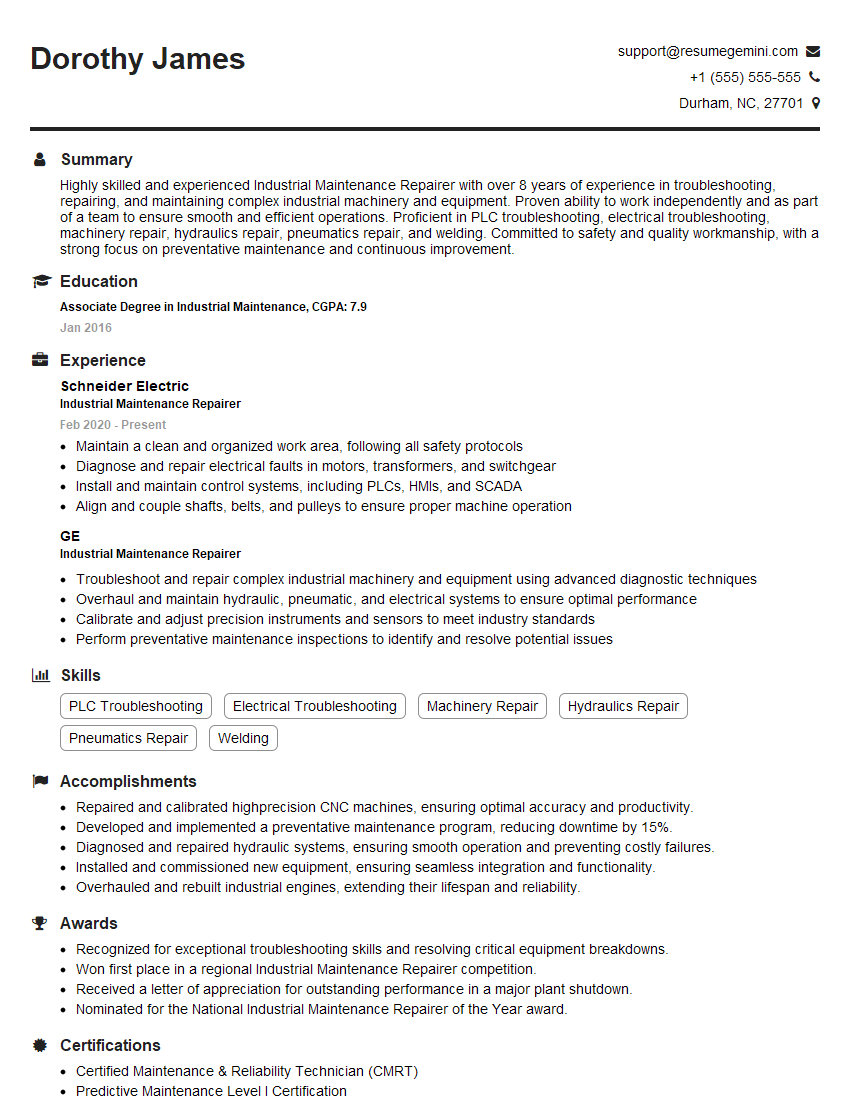

Dorothy James

Industrial Maintenance Repairer

Summary

Highly skilled and experienced Industrial Maintenance Repairer with over 8 years of experience in troubleshooting, repairing, and maintaining complex industrial machinery and equipment. Proven ability to work independently and as part of a team to ensure smooth and efficient operations. Proficient in PLC troubleshooting, electrical troubleshooting, machinery repair, hydraulics repair, pneumatics repair, and welding. Committed to safety and quality workmanship, with a strong focus on preventative maintenance and continuous improvement.

Education

Associate Degree in Industrial Maintenance

January 2016

Skills

- PLC Troubleshooting

- Electrical Troubleshooting

- Machinery Repair

- Hydraulics Repair

- Pneumatics Repair

- Welding

Work Experience

Industrial Maintenance Repairer

- Maintain a clean and organized work area, following all safety protocols

- Diagnose and repair electrical faults in motors, transformers, and switchgear

- Install and maintain control systems, including PLCs, HMIs, and SCADA

- Align and couple shafts, belts, and pulleys to ensure proper machine operation

Industrial Maintenance Repairer

- Troubleshoot and repair complex industrial machinery and equipment using advanced diagnostic techniques

- Overhaul and maintain hydraulic, pneumatic, and electrical systems to ensure optimal performance

- Calibrate and adjust precision instruments and sensors to meet industry standards

- Perform preventative maintenance inspections to identify and resolve potential issues

Accomplishments

- Repaired and calibrated highprecision CNC machines, ensuring optimal accuracy and productivity.

- Developed and implemented a preventative maintenance program, reducing downtime by 15%.

- Diagnosed and repaired hydraulic systems, ensuring smooth operation and preventing costly failures.

- Installed and commissioned new equipment, ensuring seamless integration and functionality.

- Overhauled and rebuilt industrial engines, extending their lifespan and reliability.

Awards

- Recognized for exceptional troubleshooting skills and resolving critical equipment breakdowns.

- Won first place in a regional Industrial Maintenance Repairer competition.

- Received a letter of appreciation for outstanding performance in a major plant shutdown.

- Nominated for the National Industrial Maintenance Repairer of the Year award.

Certificates

- Certified Maintenance & Reliability Technician (CMRT)

- Predictive Maintenance Level I Certification

- Infrared Thermography Certification

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Industrial Maintenance Repairer

- Highlight your skills and experience in the industry, especially in PLC troubleshooting, electrical troubleshooting, and machinery repair.

- Demonstrate your knowledge of safety protocols and commitment to quality workmanship.

- Showcase your ability to work independently and as part of a team.

- Emphasize your preventative maintenance experience and continuous improvement mindset.

- Quantify your accomplishments whenever possible to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Industrial Maintenance Repairer Resume

- Troubleshoot and repair complex industrial machinery and equipment using advanced diagnostic techniques.

- Overhaul and maintain hydraulic, pneumatic, and electrical systems to ensure optimal performance.

- Calibrate and adjust precision instruments and sensors to meet industry standards.

- Perform preventative maintenance inspections to identify and resolve potential issues.

- Maintain a clean and organized work area, following all safety protocols.

- Diagnose and repair electrical faults in motors, transformers, and switchgear.

- Install and maintain control systems, including PLCs, HMIs, and SCADA.

- Align and couple shafts, belts, and pulleys to ensure proper machine operation.

Frequently Asked Questions (FAQ’s) For Industrial Maintenance Repairer

What are the key skills required for an Industrial Maintenance Repairer?

Key skills include PLC troubleshooting, electrical troubleshooting, machinery repair, hydraulics repair, pneumatics repair, and welding.

What is the typical work environment for an Industrial Maintenance Repairer?

Industrial Maintenance Repairers typically work in manufacturing facilities, power plants, and other industrial settings. They may work indoors or outdoors, and may be exposed to noise, dust, and hazardous materials.

What are the career advancement opportunities for an Industrial Maintenance Repairer?

With experience and additional training, Industrial Maintenance Repairers can advance to positions such as Maintenance Supervisor, Maintenance Manager, or Plant Manager.

What is the job outlook for Industrial Maintenance Repairers?

The job outlook for Industrial Maintenance Repairers is expected to be good over the next few years, as there is a growing demand for skilled workers in this field.

What are the educational requirements for an Industrial Maintenance Repairer?

Most Industrial Maintenance Repairers have an associate degree in industrial maintenance or a related field. Some employers may also require certification in specific areas, such as PLC programming or electrical work.

What are the safety precautions that Industrial Maintenance Repairers must follow?

Industrial Maintenance Repairers must follow all safety protocols, such as wearing proper protective gear, using lockout/tagout procedures, and being aware of potential hazards in the work environment.