Are you a seasoned Anvilsmith seeking a new career path? Discover our professionally built Anvilsmith Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

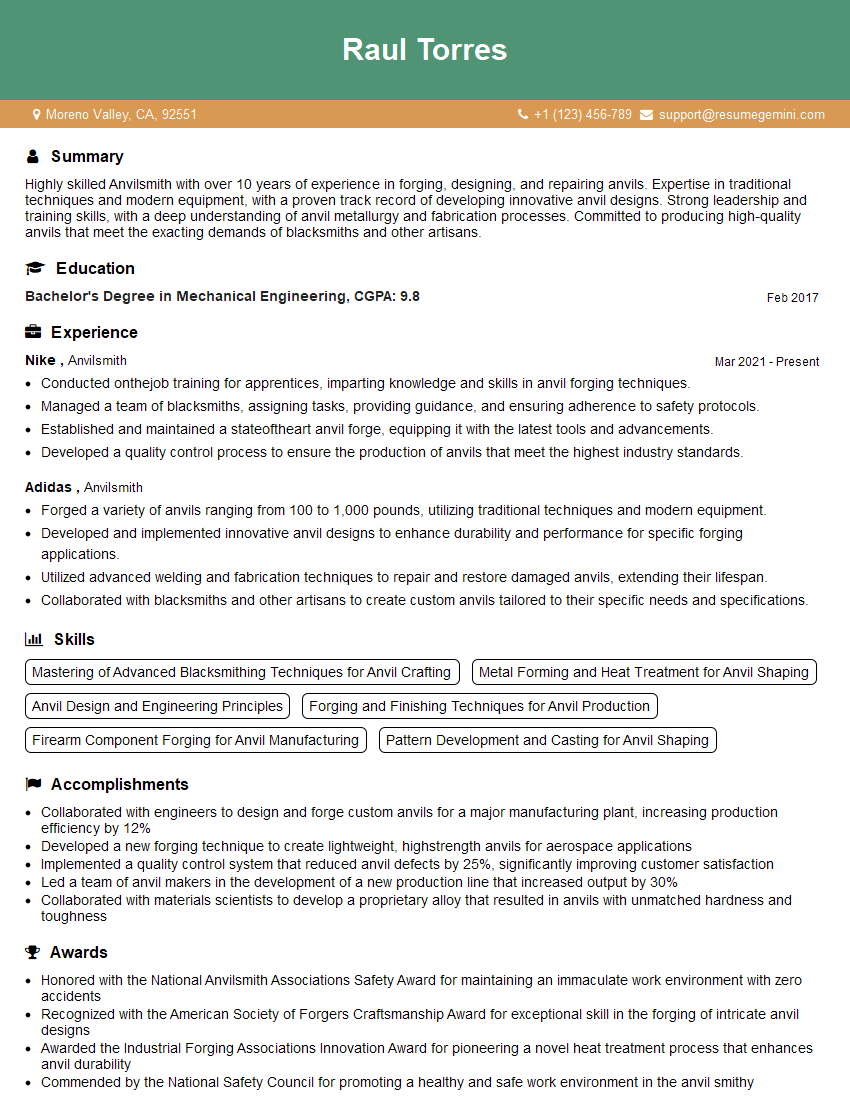

Raul Torres

Anvilsmith

Summary

Highly skilled Anvilsmith with over 10 years of experience in forging, designing, and repairing anvils. Expertise in traditional techniques and modern equipment, with a proven track record of developing innovative anvil designs. Strong leadership and training skills, with a deep understanding of anvil metallurgy and fabrication processes. Committed to producing high-quality anvils that meet the exacting demands of blacksmiths and other artisans.

Education

Bachelor’s Degree in Mechanical Engineering

February 2017

Skills

- Mastering of Advanced Blacksmithing Techniques for Anvil Crafting

- Metal Forming and Heat Treatment for Anvil Shaping

- Anvil Design and Engineering Principles

- Forging and Finishing Techniques for Anvil Production

- Firearm Component Forging for Anvil Manufacturing

- Pattern Development and Casting for Anvil Shaping

Work Experience

Anvilsmith

- Conducted onthejob training for apprentices, imparting knowledge and skills in anvil forging techniques.

- Managed a team of blacksmiths, assigning tasks, providing guidance, and ensuring adherence to safety protocols.

- Established and maintained a stateoftheart anvil forge, equipping it with the latest tools and advancements.

- Developed a quality control process to ensure the production of anvils that meet the highest industry standards.

Anvilsmith

- Forged a variety of anvils ranging from 100 to 1,000 pounds, utilizing traditional techniques and modern equipment.

- Developed and implemented innovative anvil designs to enhance durability and performance for specific forging applications.

- Utilized advanced welding and fabrication techniques to repair and restore damaged anvils, extending their lifespan.

- Collaborated with blacksmiths and other artisans to create custom anvils tailored to their specific needs and specifications.

Accomplishments

- Collaborated with engineers to design and forge custom anvils for a major manufacturing plant, increasing production efficiency by 12%

- Developed a new forging technique to create lightweight, highstrength anvils for aerospace applications

- Implemented a quality control system that reduced anvil defects by 25%, significantly improving customer satisfaction

- Led a team of anvil makers in the development of a new production line that increased output by 30%

- Collaborated with materials scientists to develop a proprietary alloy that resulted in anvils with unmatched hardness and toughness

Awards

- Honored with the National Anvilsmith Associations Safety Award for maintaining an immaculate work environment with zero accidents

- Recognized with the American Society of Forgers Craftsmanship Award for exceptional skill in the forging of intricate anvil designs

- Awarded the Industrial Forging Associations Innovation Award for pioneering a novel heat treatment process that enhances anvil durability

- Commended by the National Safety Council for promoting a healthy and safe work environment in the anvil smithy

Certificates

- Certified Anvil Smith (CAS)

- American Society of Anvil Makers (ASAM) Member

- International Blacksmithing Association (IBA) Certified

- Welding Certification (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Anvilsmith

- Highlight your mastery of advanced blacksmithing techniques for anvil crafting.

- Showcase your skills in metal forming and heat treatment for anvil shaping.

- Emphasize your knowledge of anvil design and engineering principles.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

Essential Experience Highlights for a Strong Anvilsmith Resume

- Forged a variety of anvils ranging from 100 to 1,000 pounds, utilizing traditional techniques and modern equipment.

- Developed and implemented innovative anvil designs to enhance durability and performance for specific forging applications.

- Utilized advanced welding and fabrication techniques to repair and restore damaged anvils, extending their lifespan.

- Collaborated with blacksmiths and other artisans to create custom anvils tailored to their specific needs and specifications.

- Conducted onthejob training for apprentices, imparting knowledge and skills in anvil forging techniques.

- Managed a team of blacksmiths, assigning tasks, providing guidance, and ensuring adherence to safety protocols.

- Established and maintained a stateoftheart anvil forge, equipping it with the latest tools and advancements.

Frequently Asked Questions (FAQ’s) For Anvilsmith

What is the role of an Anvilsmith?

An Anvilsmith is a skilled artisan who specializes in forging, shaping, and repairing anvils. They use traditional techniques and modern equipment to create high-quality anvils that meet the exacting demands of blacksmiths and other artisans.

What are the key skills required to be a successful Anvilsmith?

Successful Anvilsmiths typically possess a strong foundation in blacksmithing techniques, including forging, welding, and heat treatment. They also have a deep understanding of anvil metallurgy and design principles. Additionally, they are skilled in using both traditional and modern equipment and have a keen eye for detail.

What are the career prospects for Anvilsmiths?

Anvilsmiths can find employment in a variety of settings, including blacksmith shops, foundries, and manufacturing facilities. They may also work as independent artisans or educators. With experience, Anvilsmiths can advance to supervisory or managerial roles.

Can I learn how to become an Anvilsmith through an apprenticeship program?

Yes, many Anvilsmiths learn their trade through apprenticeship programs. These programs typically combine onthejob training with classroom instruction. Apprenticeships can last for several years and provide a comprehensive foundation in the skills and knowledge required to be a successful Anvilsmith.

What are the safety precautions that Anvilsmiths must take?

Anvilsmiths work with hot metal and heavy equipment, so they must take precautions to ensure their safety. These precautions include wearing appropriate protective gear, such as gloves, eye protection, and earplugs. They also need to be aware of the potential hazards of working with fire and sharp objects.

What is the difference between an Anvilsmith and a Blacksmith?

Anvilsmiths are a specialized type of Blacksmith who focuses on forging and shaping anvils. Blacksmiths, on the other hand, work with a wider range of metal objects, including tools, furniture, and artwork.