Are you a seasoned Cigar Tobacco Processing Supervisor seeking a new career path? Discover our professionally built Cigar Tobacco Processing Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

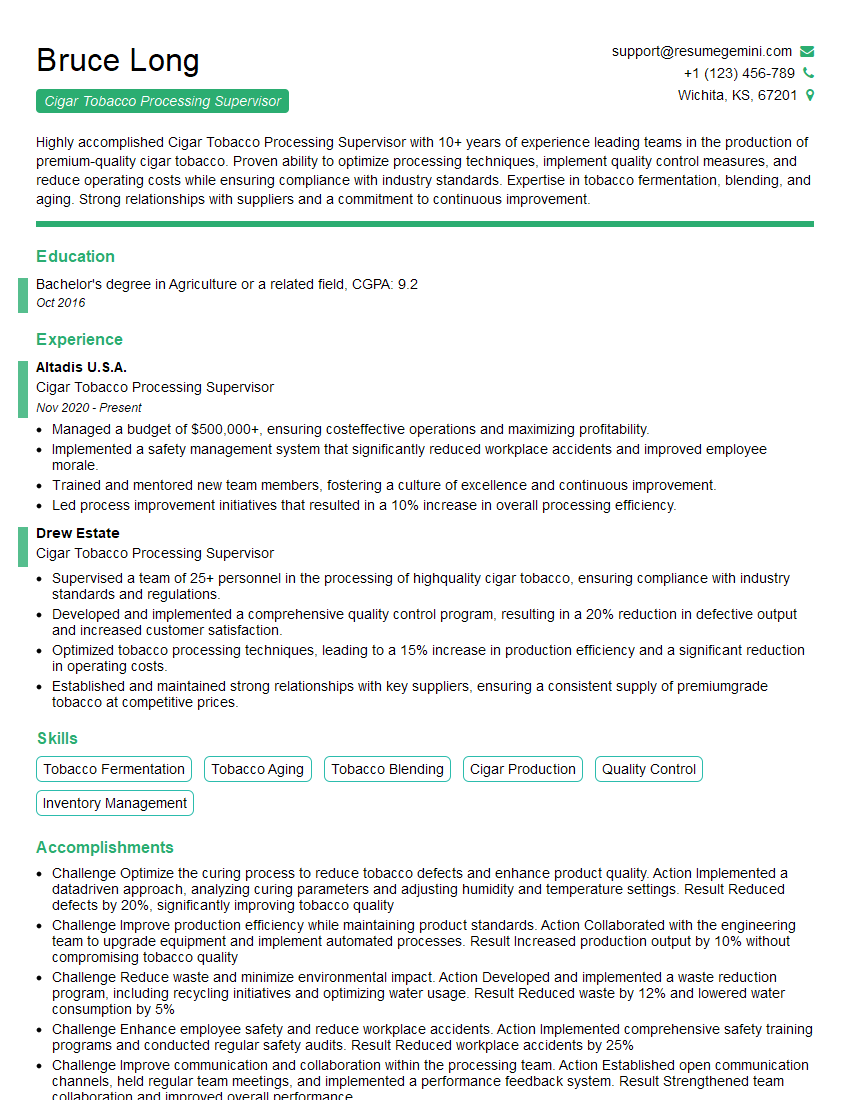

Bruce Long

Cigar Tobacco Processing Supervisor

Summary

Highly accomplished Cigar Tobacco Processing Supervisor with 10+ years of experience leading teams in the production of premium-quality cigar tobacco. Proven ability to optimize processing techniques, implement quality control measures, and reduce operating costs while ensuring compliance with industry standards. Expertise in tobacco fermentation, blending, and aging. Strong relationships with suppliers and a commitment to continuous improvement.

Education

Bachelor’s degree in Agriculture or a related field

October 2016

Skills

- Tobacco Fermentation

- Tobacco Aging

- Tobacco Blending

- Cigar Production

- Quality Control

- Inventory Management

Work Experience

Cigar Tobacco Processing Supervisor

- Managed a budget of $500,000+, ensuring costeffective operations and maximizing profitability.

- Implemented a safety management system that significantly reduced workplace accidents and improved employee morale.

- Trained and mentored new team members, fostering a culture of excellence and continuous improvement.

- Led process improvement initiatives that resulted in a 10% increase in overall processing efficiency.

Cigar Tobacco Processing Supervisor

- Supervised a team of 25+ personnel in the processing of highquality cigar tobacco, ensuring compliance with industry standards and regulations.

- Developed and implemented a comprehensive quality control program, resulting in a 20% reduction in defective output and increased customer satisfaction.

- Optimized tobacco processing techniques, leading to a 15% increase in production efficiency and a significant reduction in operating costs.

- Established and maintained strong relationships with key suppliers, ensuring a consistent supply of premiumgrade tobacco at competitive prices.

Accomplishments

- Challenge Optimize the curing process to reduce tobacco defects and enhance product quality. Action Implemented a datadriven approach, analyzing curing parameters and adjusting humidity and temperature settings. Result Reduced defects by 20%, significantly improving tobacco quality

- Challenge Improve production efficiency while maintaining product standards. Action Collaborated with the engineering team to upgrade equipment and implement automated processes. Result Increased production output by 10% without compromising tobacco quality

- Challenge Reduce waste and minimize environmental impact. Action Developed and implemented a waste reduction program, including recycling initiatives and optimizing water usage. Result Reduced waste by 12% and lowered water consumption by 5%

- Challenge Enhance employee safety and reduce workplace accidents. Action Implemented comprehensive safety training programs and conducted regular safety audits. Result Reduced workplace accidents by 25%

- Challenge Improve communication and collaboration within the processing team. Action Established open communication channels, held regular team meetings, and implemented a performance feedback system. Result Strengthened team collaboration and improved overall performance

Awards

- Received the Supervisor of the Year award for exceptional performance in leading the cigar tobacco processing team

- Recognized with the Operational Excellence Award for implementing innovative solutions that improved processing efficiency by 15%

- Awarded the Safety Champion Award for ensuring a safe and compliant work environment for the processing team

- Honored with the Team Leader of the Year award for successfully mentoring and developing highperforming processing team members

Certificates

- Certified Cigar Technician (CCT)

- Certified Tobacco Processor (CTP)

- Good Manufacturing Practices (GMP) Certification

- HACCP Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Cigar Tobacco Processing Supervisor

- Highlight your expertise in cigar tobacco processing, including fermentation, aging, and blending.

- Quantify your accomplishments with specific metrics, such as increased production efficiency and reduced operating costs.

- Demonstrate your leadership skills and ability to manage a team in a fast-paced environment.

- Emphasize your commitment to quality control and compliance with industry standards.

- Showcase your knowledge of tobacco suppliers and the ability to negotiate favorable contracts.

Essential Experience Highlights for a Strong Cigar Tobacco Processing Supervisor Resume

- Supervised a team of 25+ personnel in the processing of high-quality cigar tobacco.

- Developed and implemented a comprehensive quality control program.

- Optimized tobacco processing techniques.

- Established and maintained strong relationships with key suppliers.

- Managed a budget of $500,000+.

- Implemented a safety management system.

- Trained and mentored new team members.

- Led process improvement initiatives.

Frequently Asked Questions (FAQ’s) For Cigar Tobacco Processing Supervisor

What are the key skills required for a Cigar Tobacco Processing Supervisor?

Key skills include tobacco fermentation, aging, blending, cigar production, quality control, and inventory management.

What are the educational requirements for a Cigar Tobacco Processing Supervisor?

A bachelor’s degree in Agriculture or a related field is typically required.

What are the career prospects for a Cigar Tobacco Processing Supervisor?

With experience, Cigar Tobacco Processing Supervisors can advance to management positions, such as Production Manager or Plant Manager.

What are the challenges faced by Cigar Tobacco Processing Supervisors?

Challenges include maintaining high quality standards, managing production costs, and ensuring compliance with regulations.

What is the work environment for a Cigar Tobacco Processing Supervisor?

The work environment is typically fast-paced and requires attention to detail. Supervisors may work in a variety of settings, including processing plants, warehouses, and fields.

What are the salary expectations for a Cigar Tobacco Processing Supervisor?

Salaries vary depending on experience and qualifications, but can range from $50,000 to $100,000 per year.

What is the job outlook for Cigar Tobacco Processing Supervisors?

The job outlook is expected to be stable over the next few years.

What are the benefits of working as a Cigar Tobacco Processing Supervisor?

Benefits may include health insurance, paid time off, and a retirement plan.