Are you a seasoned Specialty Manufacturing Supervisor seeking a new career path? Discover our professionally built Specialty Manufacturing Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

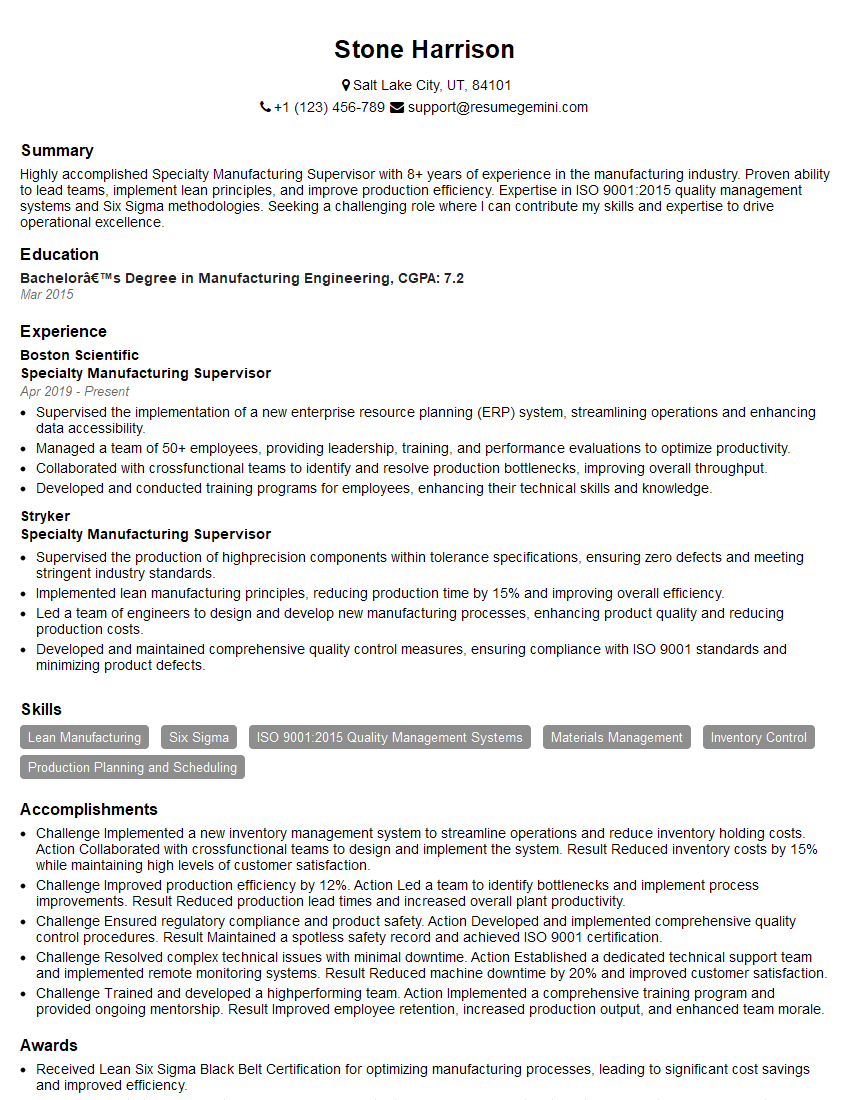

Stone Harrison

Specialty Manufacturing Supervisor

Summary

Highly accomplished Specialty Manufacturing Supervisor with 8+ years of experience in the manufacturing industry. Proven ability to lead teams, implement lean principles, and improve production efficiency. Expertise in ISO 9001:2015 quality management systems and Six Sigma methodologies. Seeking a challenging role where I can contribute my skills and expertise to drive operational excellence.

Education

Bachelor’s Degree in Manufacturing Engineering

March 2015

Skills

- Lean Manufacturing

- Six Sigma

- ISO 9001:2015 Quality Management Systems

- Materials Management

- Inventory Control

- Production Planning and Scheduling

Work Experience

Specialty Manufacturing Supervisor

- Supervised the implementation of a new enterprise resource planning (ERP) system, streamlining operations and enhancing data accessibility.

- Managed a team of 50+ employees, providing leadership, training, and performance evaluations to optimize productivity.

- Collaborated with crossfunctional teams to identify and resolve production bottlenecks, improving overall throughput.

- Developed and conducted training programs for employees, enhancing their technical skills and knowledge.

Specialty Manufacturing Supervisor

- Supervised the production of highprecision components within tolerance specifications, ensuring zero defects and meeting stringent industry standards.

- Implemented lean manufacturing principles, reducing production time by 15% and improving overall efficiency.

- Led a team of engineers to design and develop new manufacturing processes, enhancing product quality and reducing production costs.

- Developed and maintained comprehensive quality control measures, ensuring compliance with ISO 9001 standards and minimizing product defects.

Accomplishments

- Challenge Implemented a new inventory management system to streamline operations and reduce inventory holding costs. Action Collaborated with crossfunctional teams to design and implement the system. Result Reduced inventory costs by 15% while maintaining high levels of customer satisfaction.

- Challenge Improved production efficiency by 12%. Action Led a team to identify bottlenecks and implement process improvements. Result Reduced production lead times and increased overall plant productivity.

- Challenge Ensured regulatory compliance and product safety. Action Developed and implemented comprehensive quality control procedures. Result Maintained a spotless safety record and achieved ISO 9001 certification.

- Challenge Resolved complex technical issues with minimal downtime. Action Established a dedicated technical support team and implemented remote monitoring systems. Result Reduced machine downtime by 20% and improved customer satisfaction.

- Challenge Trained and developed a highperforming team. Action Implemented a comprehensive training program and provided ongoing mentorship. Result Improved employee retention, increased production output, and enhanced team morale.

Awards

- Received Lean Six Sigma Black Belt Certification for optimizing manufacturing processes, leading to significant cost savings and improved efficiency.

- Recognized with the Presidents Club Award for consistently exceeding production targets and maintaining high quality standards.

- Awarded the Safety Excellence Award for implementing a comprehensive safety program that reduced workplace accidents by 25%.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Manager of Quality/Organizational Excellence (CMQ/OE)

- Certified Lean Six Sigma Black Belt

- Certified Quality Engineer (CQE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Specialty Manufacturing Supervisor

- Highlight your experience in implementing lean manufacturing principles and reducing production time.

- Showcase your expertise in ISO 9001:2015 quality management systems and Six Sigma methodologies.

- Quantify your accomplishments whenever possible, using specific metrics and data to demonstrate your impact.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the specific role.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Specialty Manufacturing Supervisor Resume

- Supervise the production of high-precision components within tolerance specifications, ensuring zero defects and meeting stringent industry standards.

- Implement lean manufacturing principles, reducing production time and improving overall efficiency.

- Lead a team of engineers to design and develop new manufacturing processes, enhancing product quality and reducing production costs.

- Develop and maintain comprehensive quality control measures, ensuring compliance with ISO 9001 standards and minimizing product defects.

- Supervise the implementation of a new enterprise resource planning (ERP) system, streamlining operations and enhancing data accessibility.

- Manage a team of 50+ employees, providing leadership, training, and performance evaluations to optimize productivity.

- Collaborate with cross-functional teams to identify and resolve production bottlenecks, improving overall throughput.

- Develop and conduct training programs for employees, enhancing their technical skills and knowledge.

Frequently Asked Questions (FAQ’s) For Specialty Manufacturing Supervisor

What is the role of a Specialty Manufacturing Supervisor?

A Specialty Manufacturing Supervisor is responsible for overseeing the production of high-precision components within tolerance specifications, implementing lean manufacturing principles, and improving production efficiency. They also lead teams of engineers to design and develop new manufacturing processes, and ensure compliance with ISO 9001 standards.

What are the key skills required for a Specialty Manufacturing Supervisor?

Key skills for a Specialty Manufacturing Supervisor include lean manufacturing, Six Sigma, ISO 9001:2015 quality management systems, materials management, inventory control, production planning and scheduling.

What are the career prospects for a Specialty Manufacturing Supervisor?

With experience, a Specialty Manufacturing Supervisor can advance to roles such as Production Manager, Operations Manager, or Plant Manager.

What is the salary range for a Specialty Manufacturing Supervisor?

The salary range for a Specialty Manufacturing Supervisor can vary depending on experience, location, and company size. According to Indeed, the average salary for a Specialty Manufacturing Supervisor in the United States is $85,000 per year.

What are the challenges faced by Specialty Manufacturing Supervisors?

Specialty Manufacturing Supervisors may face challenges such as meeting production targets, maintaining quality standards, and managing a team of employees. They may also need to adapt to new technologies and processes.

What are some tips for becoming a successful Specialty Manufacturing Supervisor?

To become a successful Specialty Manufacturing Supervisor, it is important to have a strong understanding of lean manufacturing principles, ISO 9001 standards, and Six Sigma methodologies. It is also important to be able to lead and motivate a team of employees, and to be able to adapt to new technologies and processes.