Are you a seasoned Supervising Floorperson seeking a new career path? Discover our professionally built Supervising Floorperson Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

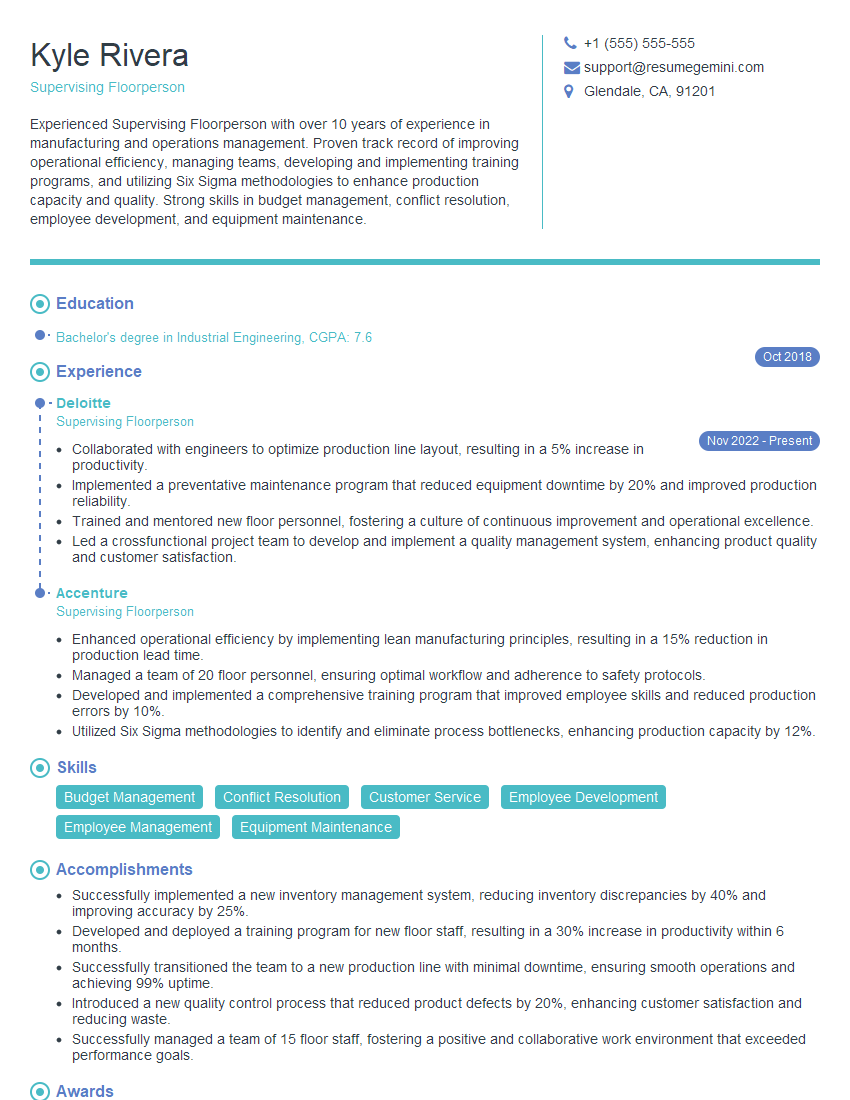

Kyle Rivera

Supervising Floorperson

Summary

Experienced Supervising Floorperson with over 10 years of experience in manufacturing and operations management. Proven track record of improving operational efficiency, managing teams, developing and implementing training programs, and utilizing Six Sigma methodologies to enhance production capacity and quality. Strong skills in budget management, conflict resolution, employee development, and equipment maintenance.

Education

Bachelor’s degree in Industrial Engineering

October 2018

Skills

- Budget Management

- Conflict Resolution

- Customer Service

- Employee Development

- Employee Management

- Equipment Maintenance

Work Experience

Supervising Floorperson

- Collaborated with engineers to optimize production line layout, resulting in a 5% increase in productivity.

- Implemented a preventative maintenance program that reduced equipment downtime by 20% and improved production reliability.

- Trained and mentored new floor personnel, fostering a culture of continuous improvement and operational excellence.

- Led a crossfunctional project team to develop and implement a quality management system, enhancing product quality and customer satisfaction.

Supervising Floorperson

- Enhanced operational efficiency by implementing lean manufacturing principles, resulting in a 15% reduction in production lead time.

- Managed a team of 20 floor personnel, ensuring optimal workflow and adherence to safety protocols.

- Developed and implemented a comprehensive training program that improved employee skills and reduced production errors by 10%.

- Utilized Six Sigma methodologies to identify and eliminate process bottlenecks, enhancing production capacity by 12%.

Accomplishments

- Successfully implemented a new inventory management system, reducing inventory discrepancies by 40% and improving accuracy by 25%.

- Developed and deployed a training program for new floor staff, resulting in a 30% increase in productivity within 6 months.

- Successfully transitioned the team to a new production line with minimal downtime, ensuring smooth operations and achieving 99% uptime.

- Introduced a new quality control process that reduced product defects by 20%, enhancing customer satisfaction and reducing waste.

- Successfully managed a team of 15 floor staff, fostering a positive and collaborative work environment that exceeded performance goals.

Awards

- Recognized with the Excellence in Operations Award for exceptional leadership in maintaining operational efficiency and meeting performance targets.

- Received the Employee of the Quarter Award for consistently exceeding performance expectations and mentoring junior team members.

- Recognized with the Safety Hero Award for implementing innovative safety measures that reduced workplace accidents by 15%.

- Received the Customer Service Excellence Award for resolving customer concerns with exceptional empathy and professionalism.

Certificates

- American Production and Inventory Control Society (APICS) Certified Production and Inventory Manager (CPIM)

- American Society of Safety Engineers (ASSE) Certified Safety Professional (CSP)

- Institute for Supply Management (ISM) Certified Professional in Supply Management (CPSM)

- OSHA 30-Hour General Industry Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Supervising Floorperson

- Highlight your experience in implementing lean manufacturing principles and quantifiable results achieved.

- Showcase your ability to manage and motivate a team of floor personnel, ensuring high performance and adherence to safety standards.

- Emphasize your expertise in utilizing Six Sigma methodologies to identify and eliminate production inefficiencies.

- Demonstrate your commitment to continuous improvement and operational excellence through training initiatives and mentorship programs.

Essential Experience Highlights for a Strong Supervising Floorperson Resume

- Supervise a team of floor personnel to ensure optimal workflow and adherence to safety protocols.

- Develop and implement comprehensive training programs to improve employee skills and reduce errors.

- Utilize Six Sigma methodologies to identify and eliminate process bottlenecks, enhancing production capacity.

- Collaborate with engineers to optimize production line layout for increased productivity.

- Implement preventative maintenance programs to reduce equipment downtime and improve production reliability.

- Train and mentor new floor personnel, fostering a culture of continuous improvement and operational excellence.

- Lead cross-functional project teams to develop and implement quality management systems, enhancing product quality and customer satisfaction.

Frequently Asked Questions (FAQ’s) For Supervising Floorperson

What are the primary responsibilities of a Supervising Floorperson?

Supervising Floorpersons are responsible for overseeing the daily operations of a production floor, including managing a team of floor personnel, implementing and maintaining quality control standards, and ensuring adherence to safety protocols.

What skills are essential for success as a Supervising Floorperson?

Essential skills for Supervising Floorpersons include strong leadership and management abilities, knowledge of lean manufacturing principles, proficiency in Six Sigma methodologies, and a deep understanding of production processes and equipment.

What are the career advancement opportunities for a Supervising Floorperson?

Supervising Floorpersons can advance their careers by taking on managerial roles, such as Production Manager, Operations Manager, or Plant Manager. They can also specialize in areas such as quality control, process improvement, or training and development.

What is the average salary for a Supervising Floorperson?

The average salary for Supervising Floorpersons can vary depending on experience, location, and industry. According to Salary.com, the average salary range is between \$60,000 \$80,000 per year.

What are the key challenges faced by Supervising Floorpersons?

Supervising Floorpersons face several challenges, including managing a large team, ensuring adherence to safety protocols, meeting production targets, and continuously improving operational efficiency.

What is the difference between a Supervising Floorperson and a Production Supervisor?

Supervising Floorpersons typically oversee a specific production area or line, while Production Supervisors have broader responsibilities for the entire production process, including planning, scheduling, and coordination.

What are the most in-demand skills for Supervising Floorpersons?

In-demand skills for Supervising Floorpersons include lean manufacturing, Six Sigma, quality control, safety management, and employee development.

What certifications are beneficial for Supervising Floorpersons?

Beneficial certifications for Supervising Floorpersons include Certified Production Manager (CPM), Certified Manufacturing Engineer (CMfgE), and Six Sigma Green Belt or Black Belt.