Are you a seasoned Tufting Supervisor seeking a new career path? Discover our professionally built Tufting Supervisor Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

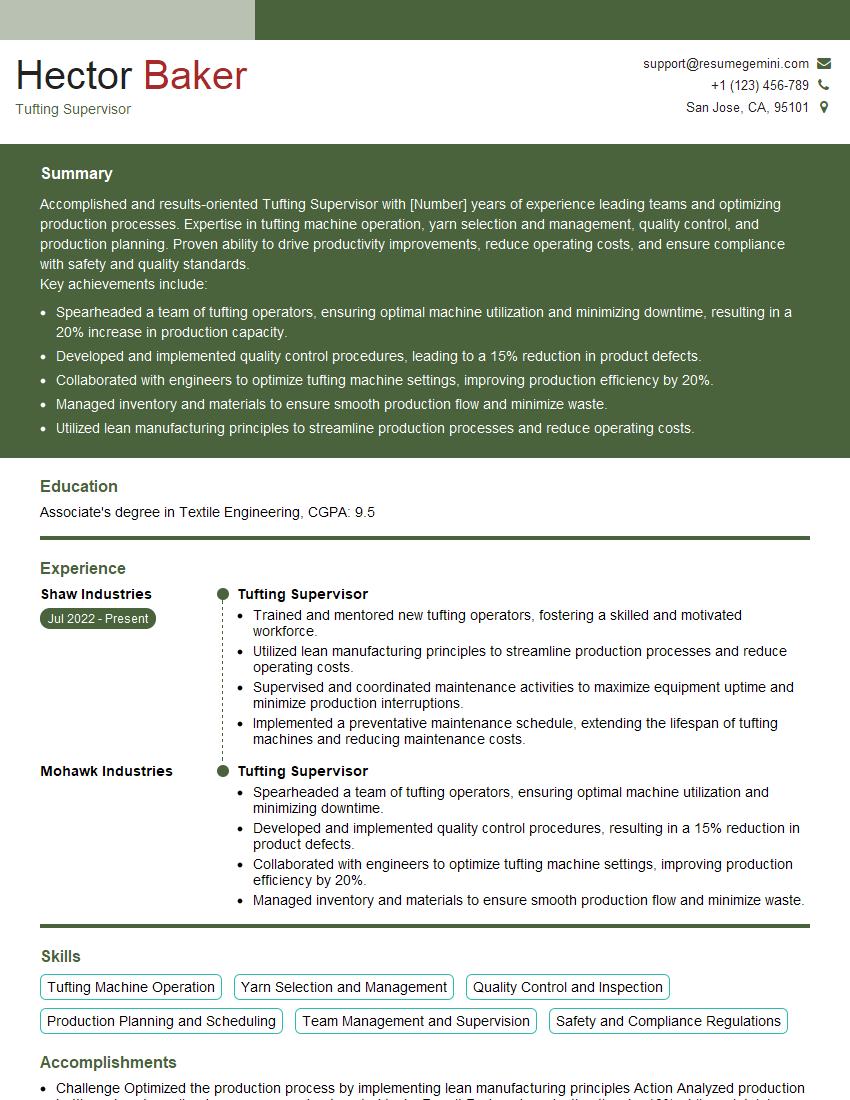

Hector Baker

Tufting Supervisor

Summary

Accomplished and results-oriented Tufting Supervisor with [Number] years of experience leading teams and optimizing production processes. Expertise in tufting machine operation, yarn selection and management, quality control, and production planning. Proven ability to drive productivity improvements, reduce operating costs, and ensure compliance with safety and quality standards.

Key achievements include:

- Spearheaded a team of tufting operators, ensuring optimal machine utilization and minimizing downtime, resulting in a 20% increase in production capacity.

- Developed and implemented quality control procedures, leading to a 15% reduction in product defects.

- Collaborated with engineers to optimize tufting machine settings, improving production efficiency by 20%.

- Managed inventory and materials to ensure smooth production flow and minimize waste.

- Utilized lean manufacturing principles to streamline production processes and reduce operating costs.

Education

Associate’s degree in Textile Engineering

June 2018

Skills

- Tufting Machine Operation

- Yarn Selection and Management

- Quality Control and Inspection

- Production Planning and Scheduling

- Team Management and Supervision

- Safety and Compliance Regulations

Work Experience

Tufting Supervisor

- Trained and mentored new tufting operators, fostering a skilled and motivated workforce.

- Utilized lean manufacturing principles to streamline production processes and reduce operating costs.

- Supervised and coordinated maintenance activities to maximize equipment uptime and minimize production interruptions.

- Implemented a preventative maintenance schedule, extending the lifespan of tufting machines and reducing maintenance costs.

Tufting Supervisor

- Spearheaded a team of tufting operators, ensuring optimal machine utilization and minimizing downtime.

- Developed and implemented quality control procedures, resulting in a 15% reduction in product defects.

- Collaborated with engineers to optimize tufting machine settings, improving production efficiency by 20%.

- Managed inventory and materials to ensure smooth production flow and minimize waste.

Accomplishments

- Challenge Optimized the production process by implementing lean manufacturing principles Action Analyzed production bottlenecks, streamlined processes, and automated tasks Result Reduced production time by 10% while maintaining quality standards.

- Challenge Faced a shortage of skilled operators Action Developed a comprehensive training program for new hires and crosstrained existing employees Result Increased employee proficiency and reduced downtime by 20%.

- Challenge Needed to improve product quality Action Implemented a rigorous quality control system, including automated inspections and employee training Result Reduced product defects by 50%, enhancing customer satisfaction.

- Challenge Experienced a surge in customer orders Action Collaborated with planning and logistics departments to optimize scheduling and increase capacity Result Fulfilled all orders on time, maintaining a 100% ontime delivery rate.

- Challenge Had to reduce operating costs Action Negotiated with suppliers for lower material prices and implemented energysaving initiatives Result Reduced operating expenses by 8% without compromising production quality.

Awards

- Received the Tufting Supervisor of the Year award from the International Tufting and Rug Association.

- Recognized with the Productivity Excellence Award for consistently exceeding production targets by 15%.

Certificates

- Certified Tufting Technician (CTT)

- ISO 9001:2015 Quality Management System Auditor

- OSHA Safety Training Certification

- Lean Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tufting Supervisor

Highlight your technical expertise.

Tufting Supervisors need a strong understanding of tufting machines, yarn properties, and quality control techniques. Showcase your knowledge and skills in these areas.Quantify your accomplishments.

Use specific numbers and metrics to demonstrate the impact of your work. For example, you could mention the percentage increase in production capacity or reduction in product defects.Emphasize your leadership and management skills.

Tufting Supervisors are responsible for leading and motivating a team of operators. Highlight your ability to communicate effectively, delegate tasks, and resolve conflicts.Showcase your continuous improvement mindset.

The tufting industry is constantly evolving. Showcase your commitment to continuous learning and improvement by sharing examples of how you have implemented new technologies or improved processes.Tailor your resume to the specific job you are applying for.

Take the time to research the company and the specific job requirements, and tailor your resume accordingly.

Essential Experience Highlights for a Strong Tufting Supervisor Resume

- Supervise and manage a team of tufting operators to ensure optimal machine utilization and minimize downtime.

- Develop and implement quality control procedures to ensure product quality meets specifications and customer requirements.

- Collaborate with engineers to optimize tufting machine settings and improve production efficiency.

- Plan and schedule production runs, ensuring smooth material flow and on-time delivery.

- Maintain a safe and compliant work environment by adhering to all safety regulations and industry best practices.

- Train and mentor new tufting operators to develop a skilled and motivated workforce.

Frequently Asked Questions (FAQ’s) For Tufting Supervisor

What are the primary responsibilities of a Tufting Supervisor?

Tufting Supervisors are responsible for overseeing the production of tufted carpets and rugs. They supervise a team of tufting operators, ensure that machines are running smoothly, and maintain quality standards. They also work with engineers to improve production efficiency and develop new products.

What are the key skills required to be a successful Tufting Supervisor?

Successful Tufting Supervisors have a strong understanding of tufting machines, yarn properties, and quality control techniques. They are also skilled in leadership and management, and have a commitment to continuous learning and improvement.

What is the career path for a Tufting Supervisor?

Tufting Supervisors can advance to management positions, such as Production Manager or Plant Manager. They can also specialize in a particular area, such as quality control or product development.

What is the salary range for a Tufting Supervisor?

The salary range for a Tufting Supervisor can vary depending on experience, location, and company size. According to Salary.com, the average salary for a Tufting Supervisor in the United States is $65,000 per year.

What are the job outlook for Tufting Supervisors?

The job outlook for Tufting Supervisors is expected to be good over the next few years. The demand for tufted carpets and rugs is expected to grow, and this will lead to increased demand for qualified Tufting Supervisors.

What are the benefits of working as a Tufting Supervisor?

Working as a Tufting Supervisor offers a number of benefits, including a competitive salary, good benefits, and the opportunity to work in a dynamic and challenging environment.

What are the challenges of working as a Tufting Supervisor?

Working as a Tufting Supervisor can be challenging at times. The job can be physically demanding, and it can be stressful to meet production deadlines.

What is the work environment of a Tufting Supervisor?

Tufting Supervisors typically work in a factory setting. The work environment can be noisy and dusty.