Are you a seasoned Tubing Assembler seeking a new career path? Discover our professionally built Tubing Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

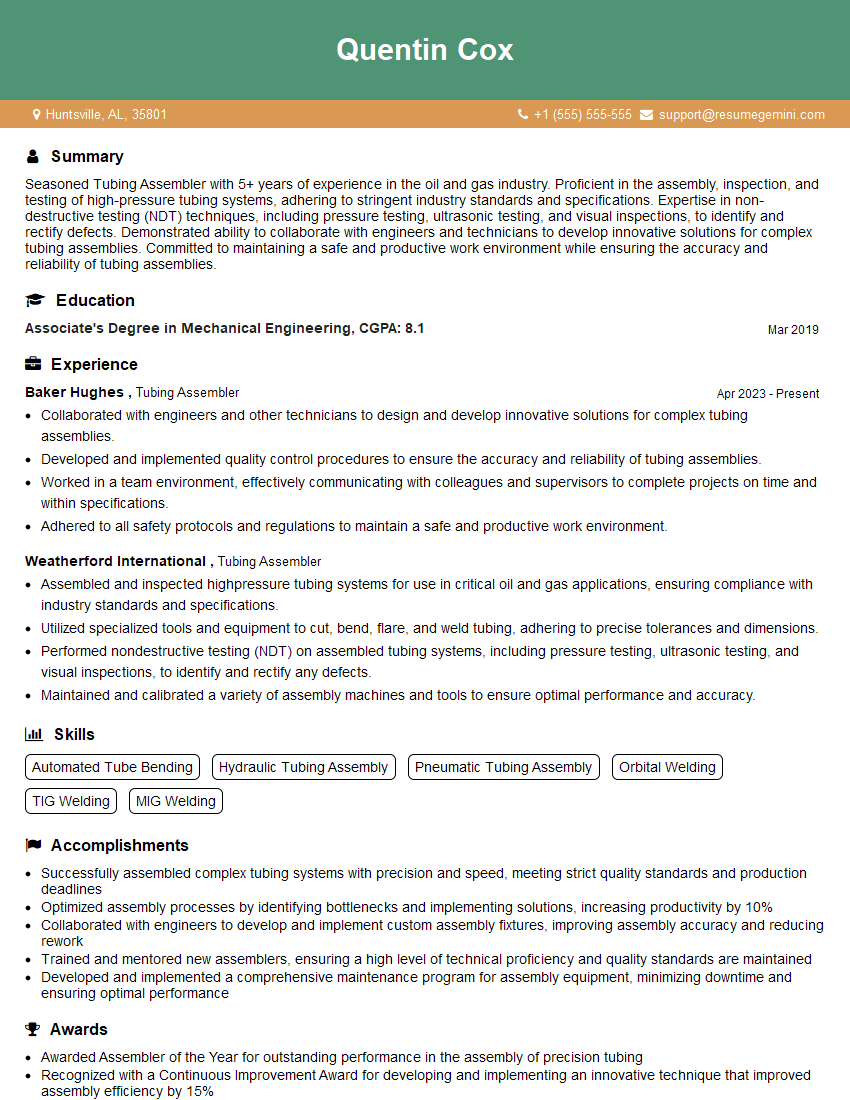

Quentin Cox

Tubing Assembler

Summary

Seasoned Tubing Assembler with 5+ years of experience in the oil and gas industry. Proficient in the assembly, inspection, and testing of high-pressure tubing systems, adhering to stringent industry standards and specifications. Expertise in non-destructive testing (NDT) techniques, including pressure testing, ultrasonic testing, and visual inspections, to identify and rectify defects. Demonstrated ability to collaborate with engineers and technicians to develop innovative solutions for complex tubing assemblies. Committed to maintaining a safe and productive work environment while ensuring the accuracy and reliability of tubing assemblies.

Education

Associate’s Degree in Mechanical Engineering

March 2019

Skills

- Automated Tube Bending

- Hydraulic Tubing Assembly

- Pneumatic Tubing Assembly

- Orbital Welding

- TIG Welding

- MIG Welding

Work Experience

Tubing Assembler

- Collaborated with engineers and other technicians to design and develop innovative solutions for complex tubing assemblies.

- Developed and implemented quality control procedures to ensure the accuracy and reliability of tubing assemblies.

- Worked in a team environment, effectively communicating with colleagues and supervisors to complete projects on time and within specifications.

- Adhered to all safety protocols and regulations to maintain a safe and productive work environment.

Tubing Assembler

- Assembled and inspected highpressure tubing systems for use in critical oil and gas applications, ensuring compliance with industry standards and specifications.

- Utilized specialized tools and equipment to cut, bend, flare, and weld tubing, adhering to precise tolerances and dimensions.

- Performed nondestructive testing (NDT) on assembled tubing systems, including pressure testing, ultrasonic testing, and visual inspections, to identify and rectify any defects.

- Maintained and calibrated a variety of assembly machines and tools to ensure optimal performance and accuracy.

Accomplishments

- Successfully assembled complex tubing systems with precision and speed, meeting strict quality standards and production deadlines

- Optimized assembly processes by identifying bottlenecks and implementing solutions, increasing productivity by 10%

- Collaborated with engineers to develop and implement custom assembly fixtures, improving assembly accuracy and reducing rework

- Trained and mentored new assemblers, ensuring a high level of technical proficiency and quality standards are maintained

- Developed and implemented a comprehensive maintenance program for assembly equipment, minimizing downtime and ensuring optimal performance

Awards

- Awarded Assembler of the Year for outstanding performance in the assembly of precision tubing

- Recognized with a Continuous Improvement Award for developing and implementing an innovative technique that improved assembly efficiency by 15%

- Received the Safety Excellence Award for maintaining an impeccable safety record and contributing to the implementation of new safety protocols

- Honored with the Team Leadership Award for effectively leading a team of assemblers and fostering a positive and productive work environment

Certificates

- AWS Certified Welder

- ASME Certified Boilermaker

- National Board Certified Boiler Inspector

- ISO 9001 Lead Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tubing Assembler

Tailor Your Resume:

Highlight your skills and experience that are most relevant to the specific job you are applying for.Showcase Your Technical Expertise:

Use technical language to demonstrate your proficiency in tubing assembly, inspection, and testing techniques.Quantify Your Accomplishments:

Use numbers and metrics to quantify your accomplishments and demonstrate the impact of your work.Emphasize Safety and Quality:

Tubing Assemblers play a critical role in ensuring the safety and quality of oil and gas systems. Highlight your commitment to these aspects.

Essential Experience Highlights for a Strong Tubing Assembler Resume

- Assembled and inspected high-pressure tubing systems for critical oil and gas applications, ensuring compliance with industry standards and specifications.

- Utilized specialized tools and equipment to cut, bend, flare, and weld tubing, adhering to precise tolerances and dimensions.

- Performed non-destructive testing (NDT) on assembled tubing systems, including pressure testing, ultrasonic testing, and visual inspections, to identify and rectify any defects.

- Maintained and calibrated a variety of assembly machines and tools to ensure optimal performance and accuracy.

- Collaborated with engineers and other technicians to design and develop innovative solutions for complex tubing assemblies.

- Developed and implemented quality control procedures to ensure the accuracy and reliability of tubing assemblies.

- Adhered to all safety protocols and regulations to maintain a safe and productive work environment.

Frequently Asked Questions (FAQ’s) For Tubing Assembler

What are the key skills for a Tubing Assembler?

Strong assembly skills, proficiency in NDT techniques, knowledge of tubing materials and welding processes, and a commitment to safety and quality.

What industries employ Tubing Assemblers?

Oil and gas, petrochemical, chemical, and other industries that utilize piping systems.

What is the average salary for a Tubing Assembler?

Varies depending on experience, location, and industry, but typically ranges from $50,000 to $80,000 annually.

What are the career advancement opportunities for Tubing Assemblers?

With experience, Tubing Assemblers can advance to roles such as Supervisor, Quality Inspector, or Engineer.

Is there a demand for Tubing Assemblers?

Yes, there is a steady demand for skilled Tubing Assemblers in the oil and gas industry and related sectors.

What are the physical demands of the job?

Tubing Assemblers may need to stand for extended periods, lift heavy objects, and work in confined spaces.

What is the work environment like for Tubing Assemblers?

Tubing Assemblers typically work in manufacturing facilities or on construction sites.

How can I prepare for a career as a Tubing Assembler?

Consider obtaining an Associate’s Degree in Mechanical Engineering or a related field, and seek opportunities to gain practical experience through internships or apprenticeships.