Are you a seasoned Electrical Controls Assembler seeking a new career path? Discover our professionally built Electrical Controls Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

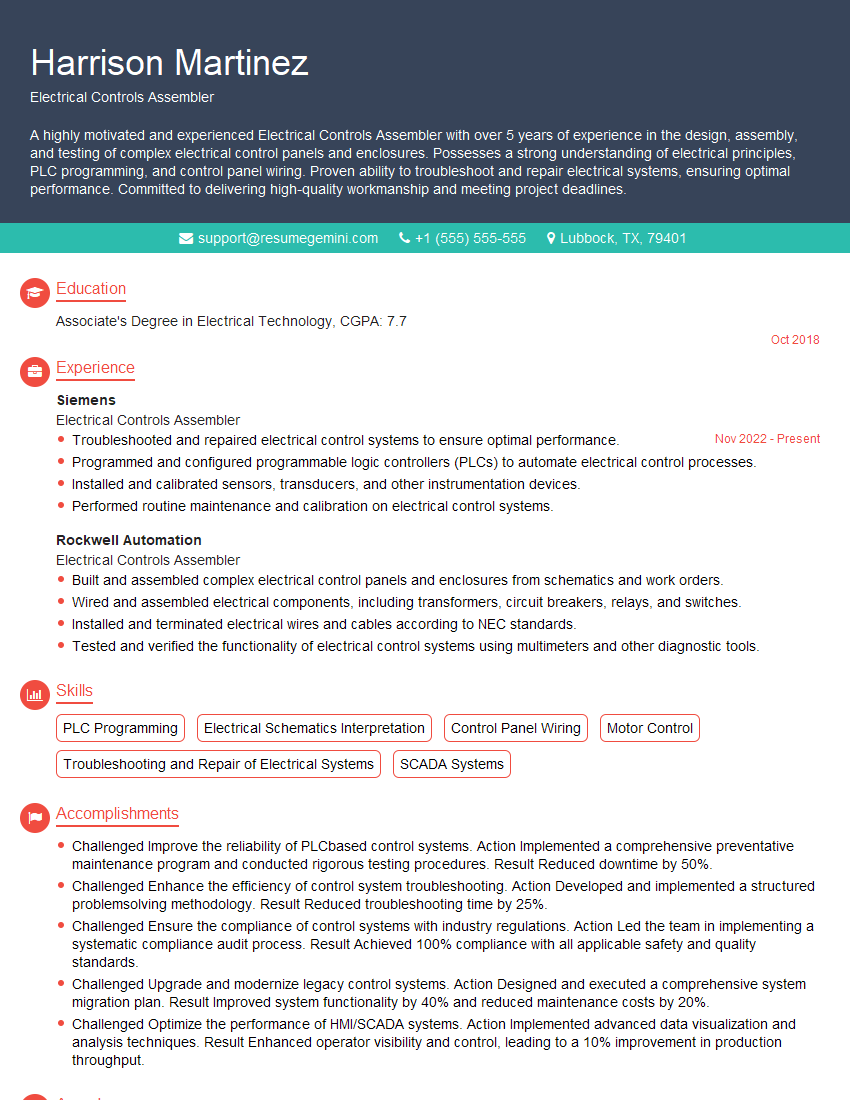

Harrison Martinez

Electrical Controls Assembler

Summary

A highly motivated and experienced Electrical Controls Assembler with over 5 years of experience in the design, assembly, and testing of complex electrical control panels and enclosures. Possesses a strong understanding of electrical principles, PLC programming, and control panel wiring. Proven ability to troubleshoot and repair electrical systems, ensuring optimal performance. Committed to delivering high-quality workmanship and meeting project deadlines.

Education

Associate’s Degree in Electrical Technology

October 2018

Skills

- PLC Programming

- Electrical Schematics Interpretation

- Control Panel Wiring

- Motor Control

- Troubleshooting and Repair of Electrical Systems

- SCADA Systems

Work Experience

Electrical Controls Assembler

- Troubleshooted and repaired electrical control systems to ensure optimal performance.

- Programmed and configured programmable logic controllers (PLCs) to automate electrical control processes.

- Installed and calibrated sensors, transducers, and other instrumentation devices.

- Performed routine maintenance and calibration on electrical control systems.

Electrical Controls Assembler

- Built and assembled complex electrical control panels and enclosures from schematics and work orders.

- Wired and assembled electrical components, including transformers, circuit breakers, relays, and switches.

- Installed and terminated electrical wires and cables according to NEC standards.

- Tested and verified the functionality of electrical control systems using multimeters and other diagnostic tools.

Accomplishments

- Challenged Improve the reliability of PLCbased control systems. Action Implemented a comprehensive preventative maintenance program and conducted rigorous testing procedures. Result Reduced downtime by 50%.

- Challenged Enhance the efficiency of control system troubleshooting. Action Developed and implemented a structured problemsolving methodology. Result Reduced troubleshooting time by 25%.

- Challenged Ensure the compliance of control systems with industry regulations. Action Led the team in implementing a systematic compliance audit process. Result Achieved 100% compliance with all applicable safety and quality standards.

- Challenged Upgrade and modernize legacy control systems. Action Designed and executed a comprehensive system migration plan. Result Improved system functionality by 40% and reduced maintenance costs by 20%.

- Challenged Optimize the performance of HMI/SCADA systems. Action Implemented advanced data visualization and analysis techniques. Result Enhanced operator visibility and control, leading to a 10% improvement in production throughput.

Awards

- Recognized for exceptional performance in the design and implementation of cuttingedge control systems for automated manufacturing lines, resulting in a 20% increase in production efficiency.

- Received the Innovative Solutions Award for developing a novel control algorithm that optimized energy consumption in electric motor drives, leading to a 15% reduction in operating costs.

- Honored with the Excellence in Automation Award for the successful integration of robotics and advanced control systems, enabling a 30% reduction in labor costs.

- Recipient of the Employee of the Year award for consistently exceeding performance expectations and demonstrating a commitment to excellence in electrical controls assembly.

Certificates

- Certified Electrical Controls Assembler (CECA)

- Certified Control System Technician (CCST)

- Certified PLC Programmer (PLCp)

- Certified Electrical Maintenance Technician (CEMT)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electrical Controls Assembler

- Highlight your skills in PLC programming, electrical schematics interpretation, and control panel wiring.

- Showcase your experience in troubleshooting and repairing electrical systems.

- Quantify your accomplishments whenever possible, using specific metrics and data.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

- Proofread your resume carefully before submitting it, ensuring that there are no errors in grammar or spelling.

Essential Experience Highlights for a Strong Electrical Controls Assembler Resume

- Built and assembled complex electrical control panels and enclosures from schematics and work orders.

- Wired and assembled electrical components, including transformers, circuit breakers, relays, and switches.

- Installed and terminated electrical wires and cables according to NEC standards.

- Tested and verified the functionality of electrical control systems using multimeters and other diagnostic tools.

- Programmed and configured programmable logic controllers (PLCs) to automate electrical control processes.

- Installed and calibrated sensors, transducers, and other instrumentation devices.

- Performed routine maintenance and calibration on electrical control systems.

Frequently Asked Questions (FAQ’s) For Electrical Controls Assembler

What is the role of an Electrical Controls Assembler?

An Electrical Controls Assembler is responsible for building, assembling, and testing electrical control panels and enclosures. They work from schematics and work orders to wire and assemble electrical components, including transformers, circuit breakers, relays, and switches. They also install and terminate electrical wires and cables according to NEC standards, and test and verify the functionality of electrical control systems using multimeters and other diagnostic tools.

What are the key skills required for an Electrical Controls Assembler?

The key skills required for an Electrical Controls Assembler include PLC programming, electrical schematics interpretation, control panel wiring, motor control, troubleshooting and repair of electrical systems, and SCADA systems.

What is the average salary for an Electrical Controls Assembler?

The average salary for an Electrical Controls Assembler in the United States is around $60,000 per year.

What are the career prospects for an Electrical Controls Assembler?

The career prospects for an Electrical Controls Assembler are good. With experience, Electrical Controls Assemblers can advance to positions such as Electrical Engineer, Controls Engineer, or Project Manager.

What are the challenges of working as an Electrical Controls Assembler?

The challenges of working as an Electrical Controls Assembler include working with high-voltage electricity, working in confined spaces, and meeting deadlines. Electrical Controls Assemblers must also be able to work independently and as part of a team.

What is the job outlook for Electrical Controls Assemblers?

The job outlook for Electrical Controls Assemblers is expected to be good over the next few years. The demand for Electrical Controls Assemblers is expected to grow as the use of automation and robotics continues to increase.

What are the educational requirements for an Electrical Controls Assembler?

The educational requirements for an Electrical Controls Assembler typically include an Associate’s Degree in Electrical Technology or a related field.