Are you a seasoned Electronic Sensing Equipment Assembler seeking a new career path? Discover our professionally built Electronic Sensing Equipment Assembler Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

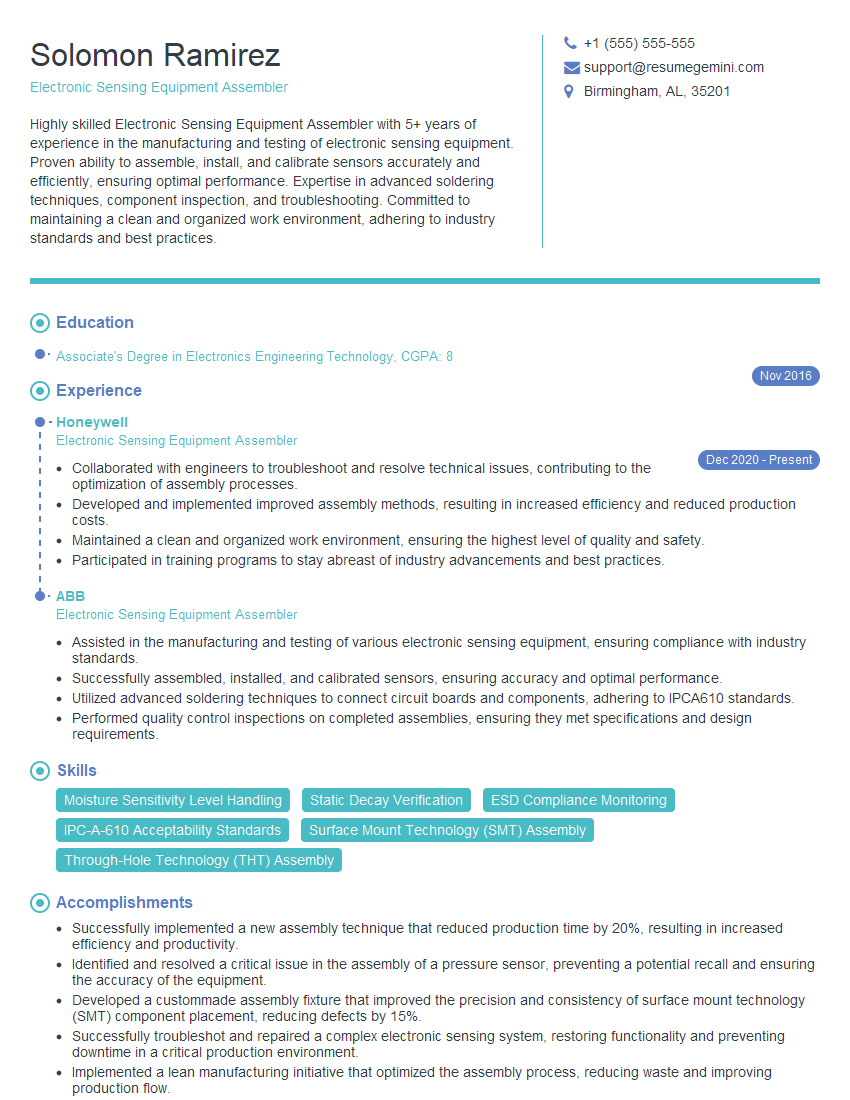

Solomon Ramirez

Electronic Sensing Equipment Assembler

Summary

Highly skilled Electronic Sensing Equipment Assembler with 5+ years of experience in the manufacturing and testing of electronic sensing equipment. Proven ability to assemble, install, and calibrate sensors accurately and efficiently, ensuring optimal performance. Expertise in advanced soldering techniques, component inspection, and troubleshooting. Committed to maintaining a clean and organized work environment, adhering to industry standards and best practices.

Education

Associate’s Degree in Electronics Engineering Technology

November 2016

Skills

- Moisture Sensitivity Level Handling

- Static Decay Verification

- ESD Compliance Monitoring

- IPC-A-610 Acceptability Standards

- Surface Mount Technology (SMT) Assembly

- Through-Hole Technology (THT) Assembly

Work Experience

Electronic Sensing Equipment Assembler

- Collaborated with engineers to troubleshoot and resolve technical issues, contributing to the optimization of assembly processes.

- Developed and implemented improved assembly methods, resulting in increased efficiency and reduced production costs.

- Maintained a clean and organized work environment, ensuring the highest level of quality and safety.

- Participated in training programs to stay abreast of industry advancements and best practices.

Electronic Sensing Equipment Assembler

- Assisted in the manufacturing and testing of various electronic sensing equipment, ensuring compliance with industry standards.

- Successfully assembled, installed, and calibrated sensors, ensuring accuracy and optimal performance.

- Utilized advanced soldering techniques to connect circuit boards and components, adhering to IPCA610 standards.

- Performed quality control inspections on completed assemblies, ensuring they met specifications and design requirements.

Accomplishments

- Successfully implemented a new assembly technique that reduced production time by 20%, resulting in increased efficiency and productivity.

- Identified and resolved a critical issue in the assembly of a pressure sensor, preventing a potential recall and ensuring the accuracy of the equipment.

- Developed a custommade assembly fixture that improved the precision and consistency of surface mount technology (SMT) component placement, reducing defects by 15%.

- Successfully troubleshot and repaired a complex electronic sensing system, restoring functionality and preventing downtime in a critical production environment.

- Implemented a lean manufacturing initiative that optimized the assembly process, reducing waste and improving production flow.

Awards

- Recipient of the Electronic Sensing Equipment Assembler of the Year Award for demonstrating exceptional skills and dedication in the assembly and testing of electronic sensing equipment.

- Recognized with the Outstanding Team Collaboration Award for exceptional teamwork in developing and implementing a new test procedure for temperature sensors.

- Honored with the Innovator of the Year Award for designing and implementing an automated testing system that significantly enhanced the efficiency and reliability of product testing.

- Received the Employee of the Month Award for consistently exceeding performance expectations and demonstrating a strong commitment to quality and customer satisfaction.

Certificates

- IPC Certified IPC-A-610 Acceptability Specialist

- ESD Association Certified ESD Technician (CET)

- OSHA 30-Hour Hazardous Waste Operations and Emergency Response

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Electronic Sensing Equipment Assembler

- Highlight your skills and experience in advanced soldering techniques, especially if you have certification or training in IPC-A-610.

- Showcase your ability to troubleshoot and resolve technical issues, providing specific examples of how you have contributed to process optimization.

- Emphasize your commitment to quality and safety, ensuring that all assembled equipment meets specifications and industry standards.

- Quantify your accomplishments whenever possible, such as reducing production costs by a specific percentage or increasing assembly efficiency by a certain amount.

- Research the company and the specific position you are applying for, tailoring your resume to highlight skills and experience that are relevant to their needs.

Essential Experience Highlights for a Strong Electronic Sensing Equipment Assembler Resume

- Assembled, installed, and calibrated a wide range of electronic sensing equipment, ensuring compliance with industry standards.

- Utilized advanced soldering techniques to connect circuit boards and components, adhering to IPC-A-610 standards.

- Performed quality control inspections on completed assemblies, verifying accuracy and adherence to specifications.

- Collaborated with engineers to troubleshoot and resolve technical issues promptly and effectively.

- Developed and implemented improved assembly methods to enhance efficiency and reduce production costs.

- Maintained a clean and organized work environment, promoting quality and safety.

- Participated in training programs to remain abreast of industry advancements and best practices.

Frequently Asked Questions (FAQ’s) For Electronic Sensing Equipment Assembler

What are the primary duties of an Electronic Sensing Equipment Assembler?

The primary duties involve assembling, installing, and calibrating various electronic sensing equipment, ensuring compliance with industry standards. They also perform quality control inspections, troubleshoot technical issues, and maintain a clean and safe work environment.

What skills are essential for an Electronic Sensing Equipment Assembler?

Essential skills include advanced soldering techniques, knowledge of IPC-A-610 standards, experience in quality control, troubleshooting abilities, and a commitment to maintaining a clean and organized workspace.

What are the career prospects for an Electronic Sensing Equipment Assembler?

With experience and additional training, Electronic Sensing Equipment Assemblers can advance to roles such as Quality Control Inspector, Manufacturing Supervisor, or Production Manager.

What is the average salary for an Electronic Sensing Equipment Assembler?

The average salary for an Electronic Sensing Equipment Assembler in the United States is around $60,000 per year, according to Salary.com.

What are the key challenges faced by Electronic Sensing Equipment Assemblers?

Key challenges include working with delicate and sensitive components, adhering to strict quality standards, and keeping up with technological advancements in the field.

What is the work environment like for an Electronic Sensing Equipment Assembler?

The work environment is typically a manufacturing facility or a production line, requiring attention to detail and adherence to safety protocols.

What are the educational requirements to become an Electronic Sensing Equipment Assembler?

While formal education is not always required, an Associate’s Degree in Electronics Engineering Technology or related field can provide a strong foundation.