Are you a seasoned Structural and Ornamental Metalwork Steel Fabricator seeking a new career path? Discover our professionally built Structural and Ornamental Metalwork Steel Fabricator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

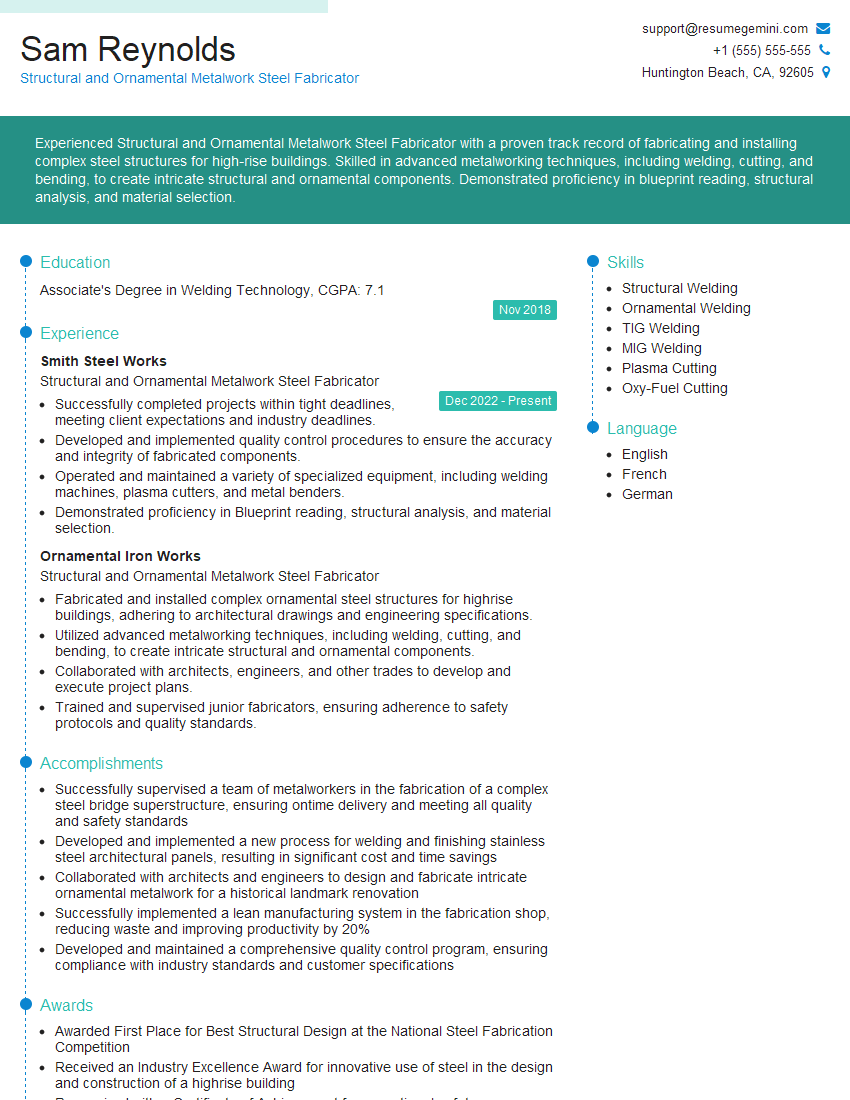

Sam Reynolds

Structural and Ornamental Metalwork Steel Fabricator

Summary

Experienced Structural and Ornamental Metalwork Steel Fabricator with a proven track record of fabricating and installing complex steel structures for high-rise buildings. Skilled in advanced metalworking techniques, including welding, cutting, and bending, to create intricate structural and ornamental components. Demonstrated proficiency in blueprint reading, structural analysis, and material selection.

Education

Associate’s Degree in Welding Technology

November 2018

Skills

- Structural Welding

- Ornamental Welding

- TIG Welding

- MIG Welding

- Plasma Cutting

- Oxy-Fuel Cutting

Work Experience

Structural and Ornamental Metalwork Steel Fabricator

- Successfully completed projects within tight deadlines, meeting client expectations and industry deadlines.

- Developed and implemented quality control procedures to ensure the accuracy and integrity of fabricated components.

- Operated and maintained a variety of specialized equipment, including welding machines, plasma cutters, and metal benders.

- Demonstrated proficiency in Blueprint reading, structural analysis, and material selection.

Structural and Ornamental Metalwork Steel Fabricator

- Fabricated and installed complex ornamental steel structures for highrise buildings, adhering to architectural drawings and engineering specifications.

- Utilized advanced metalworking techniques, including welding, cutting, and bending, to create intricate structural and ornamental components.

- Collaborated with architects, engineers, and other trades to develop and execute project plans.

- Trained and supervised junior fabricators, ensuring adherence to safety protocols and quality standards.

Accomplishments

- Successfully supervised a team of metalworkers in the fabrication of a complex steel bridge superstructure, ensuring ontime delivery and meeting all quality and safety standards

- Developed and implemented a new process for welding and finishing stainless steel architectural panels, resulting in significant cost and time savings

- Collaborated with architects and engineers to design and fabricate intricate ornamental metalwork for a historical landmark renovation

- Successfully implemented a lean manufacturing system in the fabrication shop, reducing waste and improving productivity by 20%

- Developed and maintained a comprehensive quality control program, ensuring compliance with industry standards and customer specifications

Awards

- Awarded First Place for Best Structural Design at the National Steel Fabrication Competition

- Received an Industry Excellence Award for innovative use of steel in the design and construction of a highrise building

- Recognized with a Certificate of Achievement for exceptional safety performance on a largescale steel fabrication project

- Named Top Fabricator for the state by the American Institute of Steel Construction

Certificates

- American Welding Society (AWS) Certified Welder

- National Institute for Certification in Engineering Technologies (NICET) Certified Technician

- Ironworkers International (IW)

- Occupational Safety and Health Administration (OSHA) 30-Hour Construction Safety

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Structural and Ornamental Metalwork Steel Fabricator

- Highlight your skills in advanced metalworking techniques, such as welding, cutting, and bending.

- Showcase your experience in fabricating and installing complex steel structures for high-rise buildings.

- Emphasize your ability to work independently and as part of a team.

- Include examples of projects you have worked on and the results you achieved.

Essential Experience Highlights for a Strong Structural and Ornamental Metalwork Steel Fabricator Resume

- Fabricated and installed complex ornamental steel structures for high-rise buildings, adhering to architectural drawings and engineering specifications.

- Utilized advanced metalworking techniques, including welding, cutting, and bending, to create intricate structural and ornamental components.

- Collaborated with architects, engineers, and other trades to develop and execute project plans.

- Trained and supervised junior fabricators, ensuring adherence to safety protocols and quality standards.

- Successfully completed projects within tight deadlines, meeting client expectations and industry deadlines.

- Developed and implemented quality control procedures to ensure the accuracy and integrity of fabricated components.

- Operated and maintained a variety of specialized equipment, including welding machines, plasma cutters, and metal benders.

Frequently Asked Questions (FAQ’s) For Structural and Ornamental Metalwork Steel Fabricator

What are the key skills required to be a Structural and Ornamental Metalwork Steel Fabricator?

The key skills required to be a Structural and Ornamental Metalwork Steel Fabricator include: welding, cutting, bending, blueprint reading, structural analysis, and material selection.

What is the work environment of a Structural and Ornamental Metalwork Steel Fabricator?

The work environment of a Structural and Ornamental Metalwork Steel Fabricator is typically a fabrication shop or construction site. The work can be physically demanding and requires attention to detail.

What are the career prospects for a Structural and Ornamental Metalwork Steel Fabricator?

The career prospects for a Structural and Ornamental Metalwork Steel Fabricator are good. There is a high demand for skilled fabricators in the construction industry.

What are the educational requirements to become a Structural and Ornamental Metalwork Steel Fabricator?

The minimum educational requirement to become a Structural and Ornamental Metalwork Steel Fabricator is a high school diploma or equivalent. However, many employers prefer candidates with an Associate’s Degree in Welding Technology or a related field.

What are the safety precautions that should be taken when working as a Structural and Ornamental Metalwork Steel Fabricator?

The safety precautions that should be taken when working as a Structural and Ornamental Metalwork Steel Fabricator include: wearing appropriate safety gear, such as gloves, safety glasses, and a hard hat; using proper lifting techniques; and being aware of the hazards associated with working with heavy machinery.

What are the different types of welding used in Structural and Ornamental Metalwork Steel Fabrication?

The different types of welding used in Structural and Ornamental Metalwork Steel Fabrication include: arc welding, MIG welding, TIG welding, and oxy-fuel welding.