Are you a seasoned Weld Fitter seeking a new career path? Discover our professionally built Weld Fitter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

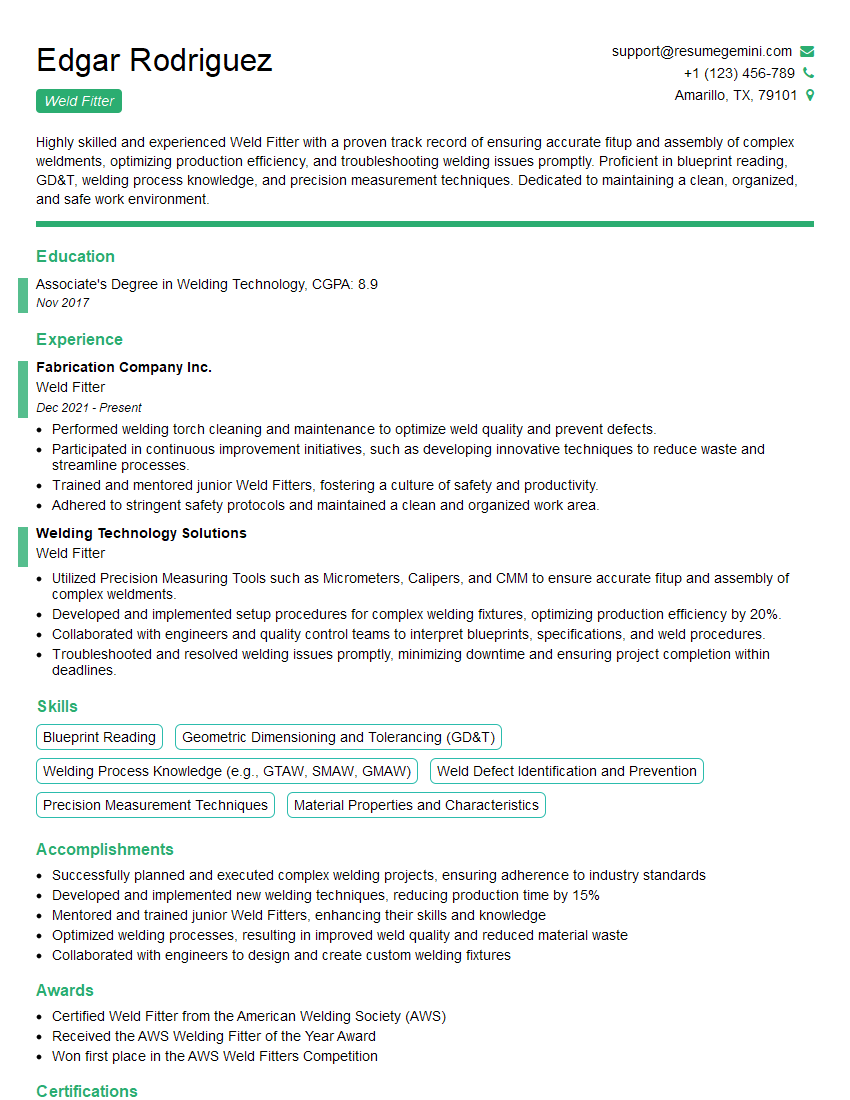

Edgar Rodriguez

Weld Fitter

Summary

Highly skilled and experienced Weld Fitter with a proven track record of ensuring accurate fitup and assembly of complex weldments, optimizing production efficiency, and troubleshooting welding issues promptly. Proficient in blueprint reading, GD&T, welding process knowledge, and precision measurement techniques. Dedicated to maintaining a clean, organized, and safe work environment.

Education

Associate’s Degree in Welding Technology

November 2017

Skills

- Blueprint Reading

- Geometric Dimensioning and Tolerancing (GD&T)

- Welding Process Knowledge (e.g., GTAW, SMAW, GMAW)

- Weld Defect Identification and Prevention

- Precision Measurement Techniques

- Material Properties and Characteristics

Work Experience

Weld Fitter

- Performed welding torch cleaning and maintenance to optimize weld quality and prevent defects.

- Participated in continuous improvement initiatives, such as developing innovative techniques to reduce waste and streamline processes.

- Trained and mentored junior Weld Fitters, fostering a culture of safety and productivity.

- Adhered to stringent safety protocols and maintained a clean and organized work area.

Weld Fitter

- Utilized Precision Measuring Tools such as Micrometers, Calipers, and CMM to ensure accurate fitup and assembly of complex weldments.

- Developed and implemented setup procedures for complex welding fixtures, optimizing production efficiency by 20%.

- Collaborated with engineers and quality control teams to interpret blueprints, specifications, and weld procedures.

- Troubleshooted and resolved welding issues promptly, minimizing downtime and ensuring project completion within deadlines.

Accomplishments

- Successfully planned and executed complex welding projects, ensuring adherence to industry standards

- Developed and implemented new welding techniques, reducing production time by 15%

- Mentored and trained junior Weld Fitters, enhancing their skills and knowledge

- Optimized welding processes, resulting in improved weld quality and reduced material waste

- Collaborated with engineers to design and create custom welding fixtures

Awards

- Certified Weld Fitter from the American Welding Society (AWS)

- Received the AWS Welding Fitter of the Year Award

- Won first place in the AWS Weld Fitters Competition

Certificates

- AWS Certified Welder

- ASME Boiler and Pressure Vessel Code

- National Institute for Certification in Engineering Technologies (NICET)

- American Welding Society (AWS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Weld Fitter

- Highlight your proficiency in precision measurement techniques, ensuring dimensional accuracy and structural integrity.

- Showcase your ability to optimize production efficiency through the development and implementation of innovative setup procedures.

- Emphasize your collaborative nature and experience in working closely with engineers and quality control teams.

- Quantify your accomplishments, such as the percentage reduction in downtime achieved through prompt troubleshooting and issue resolution.

- Demonstrate your commitment to continuous improvement and your innovative contributions to streamlining processes.

Essential Experience Highlights for a Strong Weld Fitter Resume

- Utilize precision measuring tools to ensure accurate fitup and assembly of complex weldments, ensuring dimensional accuracy and structural integrity.

- Develop and implement setup procedures for complex welding fixtures, optimizing production efficiency and reducing manufacturing lead times.

- Collaborate with engineers and quality control teams to interpret blueprints, specifications, and weld procedures, ensuring adherence to design requirements and industry standards.

- Troubleshoot and resolve welding issues promptly, minimizing downtime and ensuring project completion within deadlines.

- Perform welding torch cleaning and maintenance to optimize weld quality and prevent defects, ensuring consistent weld quality and minimizing rework.

- Participate in continuous improvement initiatives, such as developing innovative techniques to reduce waste and streamline processes, contributing to overall productivity and cost-effectiveness.

- Train and mentor junior Weld Fitters, fostering a culture of safety, productivity, and professional development.

- Adhere to stringent safety protocols and maintain a clean and organized work area, ensuring a safe and compliant work environment.

Frequently Asked Questions (FAQ’s) For Weld Fitter

What is the primary role of a Weld Fitter?

Weld Fitters play a crucial role in ensuring the accuracy and quality of welded assemblies. They utilize precision measuring tools, develop setup procedures, and collaborate with engineers to ensure that weldments meet design requirements and industry standards.

What are the essential skills required for a Weld Fitter?

Weld Fitters must possess strong technical skills, including proficiency in blueprint reading, GD&T, welding process knowledge, and precision measurement techniques. They should also have a good understanding of material properties and characteristics.

What are the career prospects for Weld Fitters?

Weld Fitters are in high demand due to the increasing need for skilled tradespeople in various industries, including manufacturing, construction, and automotive. With experience and additional certifications, Weld Fitters can advance to supervisory or management roles.

How can I become a Weld Fitter?

To become a Weld Fitter, you can pursue an Associate’s Degree in Welding Technology or complete an apprenticeship program. These programs provide hands-on training and theoretical knowledge necessary for the role.

What is the average salary for a Weld Fitter?

The average salary for a Weld Fitter can vary depending on experience, location, and industry. According to Indeed, the average salary for a Weld Fitter in the United States is around $21.81 per hour.

What are the safety precautions that Weld Fitters must follow?

Weld Fitters must follow strict safety protocols to protect themselves and others from potential hazards. These precautions include wearing appropriate protective gear, maintaining a clean and organized work area, and adhering to established safety regulations.