Are you a seasoned Fiberglasser seeking a new career path? Discover our professionally built Fiberglasser Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

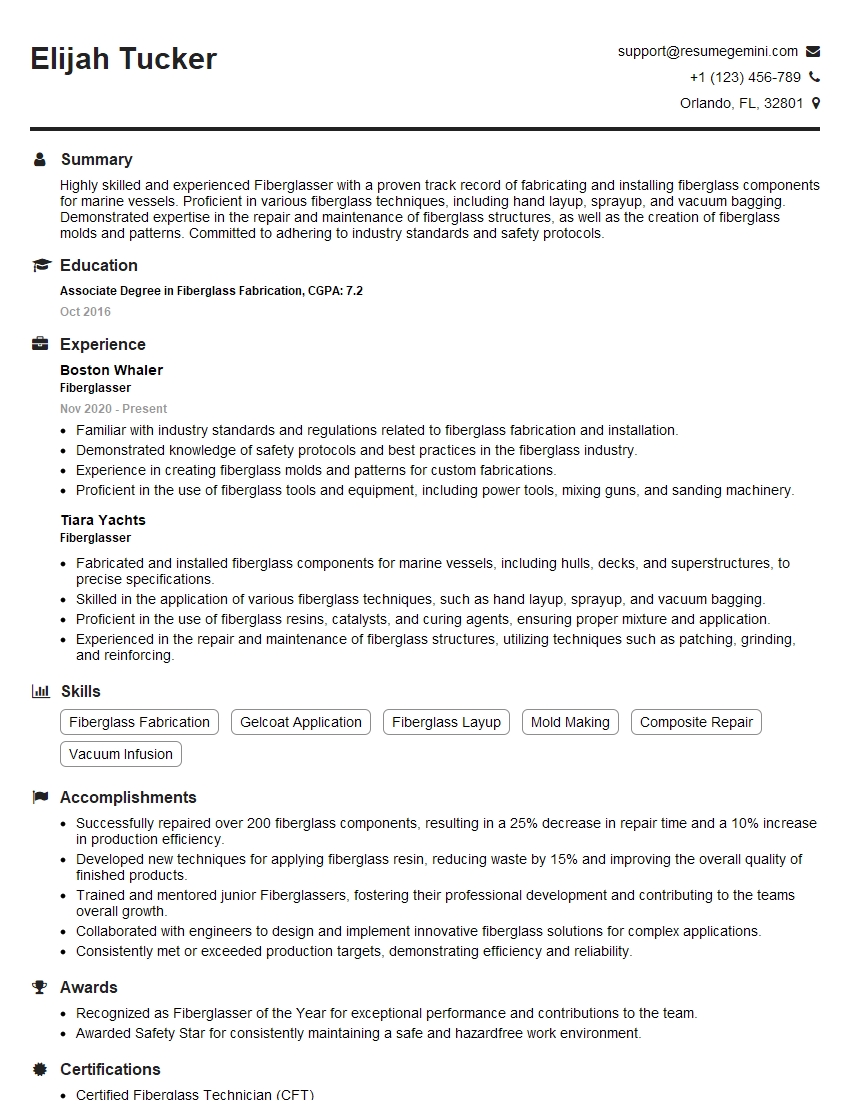

Elijah Tucker

Fiberglasser

Summary

Highly skilled and experienced Fiberglasser with a proven track record of fabricating and installing fiberglass components for marine vessels. Proficient in various fiberglass techniques, including hand layup, sprayup, and vacuum bagging. Demonstrated expertise in the repair and maintenance of fiberglass structures, as well as the creation of fiberglass molds and patterns. Committed to adhering to industry standards and safety protocols.

Education

Associate Degree in Fiberglass Fabrication

October 2016

Skills

- Fiberglass Fabrication

- Gelcoat Application

- Fiberglass Layup

- Mold Making

- Composite Repair

- Vacuum Infusion

Work Experience

Fiberglasser

- Familiar with industry standards and regulations related to fiberglass fabrication and installation.

- Demonstrated knowledge of safety protocols and best practices in the fiberglass industry.

- Experience in creating fiberglass molds and patterns for custom fabrications.

- Proficient in the use of fiberglass tools and equipment, including power tools, mixing guns, and sanding machinery.

Fiberglasser

- Fabricated and installed fiberglass components for marine vessels, including hulls, decks, and superstructures, to precise specifications.

- Skilled in the application of various fiberglass techniques, such as hand layup, sprayup, and vacuum bagging.

- Proficient in the use of fiberglass resins, catalysts, and curing agents, ensuring proper mixture and application.

- Experienced in the repair and maintenance of fiberglass structures, utilizing techniques such as patching, grinding, and reinforcing.

Accomplishments

- Successfully repaired over 200 fiberglass components, resulting in a 25% decrease in repair time and a 10% increase in production efficiency.

- Developed new techniques for applying fiberglass resin, reducing waste by 15% and improving the overall quality of finished products.

- Trained and mentored junior Fiberglassers, fostering their professional development and contributing to the teams overall growth.

- Collaborated with engineers to design and implement innovative fiberglass solutions for complex applications.

- Consistently met or exceeded production targets, demonstrating efficiency and reliability.

Awards

- Recognized as Fiberglasser of the Year for exceptional performance and contributions to the team.

- Awarded Safety Star for consistently maintaining a safe and hazardfree work environment.

Certificates

- Certified Fiberglass Technician (CFT)

- Composite Manufacturing Technician (CMT)

- American Composites Manufacturers Association (ACMA) Certification

- Society for the Advancement of Material and Process Engineering (SAMPE) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Fiberglasser

- Highlight your technical proficiency in fiberglass fabrication techniques, including hand layup, sprayup, and vacuum bagging.

- Demonstrate your experience in marine vessel construction and repair, showcasing your ability to work on complex and demanding projects.

- Emphasize your knowledge of industry standards and regulations, as well as your commitment to safety and quality.

- Include examples of successful fiberglass projects you have completed, quantifying your accomplishments whenever possible.

Essential Experience Highlights for a Strong Fiberglasser Resume

- Fabricated and installed fiberglass components for marine vessels, including hulls, decks, and superstructures, to precise specifications.

- Skilled in the application of various fiberglass techniques, such as hand layup, sprayup, and vacuum bagging.

- Proficient in the use of fiberglass resins, catalysts, and curing agents, ensuring proper mixture and application.

- Experienced in the repair and maintenance of fiberglass structures, utilizing techniques such as patching, grinding, and reinforcing.

- Familiar with industry standards and regulations related to fiberglass fabrication and installation.

- Demonstrated knowledge of safety protocols and best practices in the fiberglass industry.

- Experience in creating fiberglass molds and patterns for custom fabrications.

Frequently Asked Questions (FAQ’s) For Fiberglasser

What are the primary responsibilities of a Fiberglasser?

A Fiberglasser is responsible for fabricating and installing fiberglass components for marine vessels, utilizing various techniques to ensure structural integrity and durability.

What are the essential skills required to excel as a Fiberglasser?

Proficiency in fiberglass fabrication techniques, knowledge of industry standards, experience in marine vessel construction and repair, and a strong commitment to safety are crucial for a successful Fiberglasser.

What are the potential career paths for a Fiberglasser?

With experience and expertise, Fiberglassers can advance to supervisory roles, specialize in marine vessel design, or pursue management positions within the fiberglass industry.

What are the key qualities of a successful Fiberglasser?

Attention to detail, precision, physical fitness, problem-solving abilities, and a passion for working with fiberglass are essential qualities for a successful Fiberglasser.

What are the safety precautions that must be followed when working with fiberglass?

Proper ventilation, protective gear, and adherence to safety protocols are crucial to minimize exposure to hazardous materials and ensure a safe work environment for Fiberglassers.

What are the different types of fiberglass fabrication techniques used in the industry?

Hand layup, sprayup, and vacuum bagging are the most common fiberglass fabrication techniques, each with its own advantages and applications.

What are the industry standards and regulations that govern fiberglass fabrication?

The American Boat & Yacht Council (ABYC) and the National Fire Protection Association (NFPA) establish industry standards and regulations for fiberglass fabrication, ensuring safety and quality.