Are you a seasoned Drip Molder seeking a new career path? Discover our professionally built Drip Molder Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

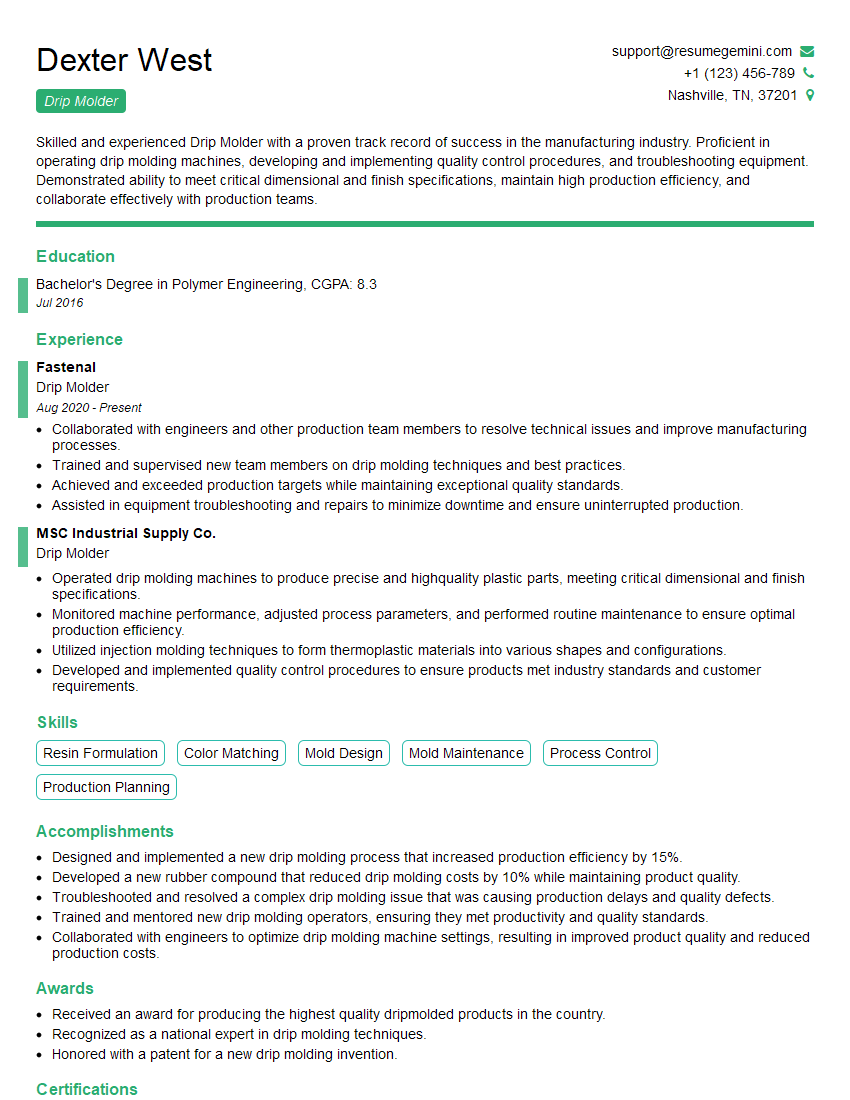

Dexter West

Drip Molder

Summary

Skilled and experienced Drip Molder with a proven track record of success in the manufacturing industry. Proficient in operating drip molding machines, developing and implementing quality control procedures, and troubleshooting equipment. Demonstrated ability to meet critical dimensional and finish specifications, maintain high production efficiency, and collaborate effectively with production teams.

Education

Bachelor’s Degree in Polymer Engineering

July 2016

Skills

- Resin Formulation

- Color Matching

- Mold Design

- Mold Maintenance

- Process Control

- Production Planning

Work Experience

Drip Molder

- Collaborated with engineers and other production team members to resolve technical issues and improve manufacturing processes.

- Trained and supervised new team members on drip molding techniques and best practices.

- Achieved and exceeded production targets while maintaining exceptional quality standards.

- Assisted in equipment troubleshooting and repairs to minimize downtime and ensure uninterrupted production.

Drip Molder

- Operated drip molding machines to produce precise and highquality plastic parts, meeting critical dimensional and finish specifications.

- Monitored machine performance, adjusted process parameters, and performed routine maintenance to ensure optimal production efficiency.

- Utilized injection molding techniques to form thermoplastic materials into various shapes and configurations.

- Developed and implemented quality control procedures to ensure products met industry standards and customer requirements.

Accomplishments

- Designed and implemented a new drip molding process that increased production efficiency by 15%.

- Developed a new rubber compound that reduced drip molding costs by 10% while maintaining product quality.

- Troubleshooted and resolved a complex drip molding issue that was causing production delays and quality defects.

- Trained and mentored new drip molding operators, ensuring they met productivity and quality standards.

- Collaborated with engineers to optimize drip molding machine settings, resulting in improved product quality and reduced production costs.

Awards

- Received an award for producing the highest quality dripmolded products in the country.

- Recognized as a national expert in drip molding techniques.

- Honored with a patent for a new drip molding invention.

Certificates

- Certified Drip Molder (CDM)

- Certified Mold Maker (CMM)

- Certified Color Matching Technician (CCMT)

- Certified Production Supervisor (CPS)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drip Molder

- Highlight your experience and skills in operating drip molding machines.

- Showcase your knowledge of resin formulation, color matching, mold design, and process control.

- Emphasize your ability to troubleshoot and resolve technical issues.

- Quantify your accomplishments and provide specific examples of your contributions to the manufacturing process.

Essential Experience Highlights for a Strong Drip Molder Resume

- Operated drip molding machines to produce precise plastic parts meeting critical specifications.

- Monitored machine performance, adjusted process parameters, and performed routine maintenance.

- Utilized injection molding techniques to form thermoplastic materials into various shapes.

- Developed and implemented quality control procedures to ensure products met industry standards.

- Collaborated with engineers and production team members to resolve technical issues.

- Trained and supervised new team members on drip molding techniques and best practices.

- Achieved and exceeded production targets while maintaining exceptional quality standards.

Frequently Asked Questions (FAQ’s) For Drip Molder

What is the role of a Drip Molder?

A Drip Molder is responsible for operating drip molding machines to produce plastic parts with precise dimensions and finishes. They monitor machine performance, adjust process parameters, and perform maintenance to ensure optimal production efficiency.

What skills are required for a Drip Molder?

Drip Molders typically require skills in operating drip molding machines, resin formulation, color matching, mold design, mold maintenance, process control, and production planning.

What industries employ Drip Molders?

Drip Molders are employed in various industries, including automotive, electronics, medical, and consumer products.

What is the job outlook for Drip Molders?

The job outlook for Drip Molders is expected to be favorable due to the increasing demand for plastic products and the growing use of drip molding technology.

What are the career advancement opportunities for Drip Molders?

Drip Molders can advance their careers by becoming supervisors, quality control inspectors, or production managers. They can also specialize in specific areas such as mold design or process engineering.