Are you a seasoned Formula Mixer seeking a new career path? Discover our professionally built Formula Mixer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

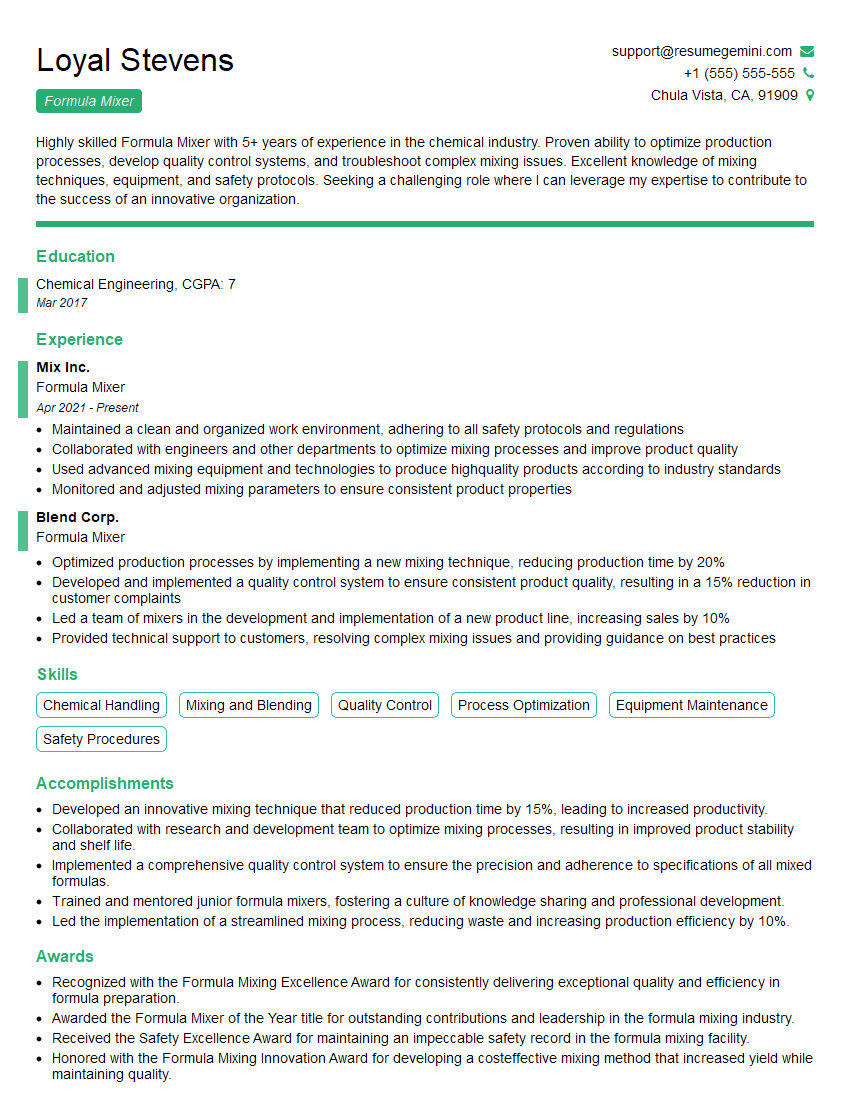

Loyal Stevens

Formula Mixer

Summary

Highly skilled Formula Mixer with 5+ years of experience in the chemical industry. Proven ability to optimize production processes, develop quality control systems, and troubleshoot complex mixing issues. Excellent knowledge of mixing techniques, equipment, and safety protocols. Seeking a challenging role where I can leverage my expertise to contribute to the success of an innovative organization.

Education

Chemical Engineering

March 2017

Skills

- Chemical Handling

- Mixing and Blending

- Quality Control

- Process Optimization

- Equipment Maintenance

- Safety Procedures

Work Experience

Formula Mixer

- Maintained a clean and organized work environment, adhering to all safety protocols and regulations

- Collaborated with engineers and other departments to optimize mixing processes and improve product quality

- Used advanced mixing equipment and technologies to produce highquality products according to industry standards

- Monitored and adjusted mixing parameters to ensure consistent product properties

Formula Mixer

- Optimized production processes by implementing a new mixing technique, reducing production time by 20%

- Developed and implemented a quality control system to ensure consistent product quality, resulting in a 15% reduction in customer complaints

- Led a team of mixers in the development and implementation of a new product line, increasing sales by 10%

- Provided technical support to customers, resolving complex mixing issues and providing guidance on best practices

Accomplishments

- Developed an innovative mixing technique that reduced production time by 15%, leading to increased productivity.

- Collaborated with research and development team to optimize mixing processes, resulting in improved product stability and shelf life.

- Implemented a comprehensive quality control system to ensure the precision and adherence to specifications of all mixed formulas.

- Trained and mentored junior formula mixers, fostering a culture of knowledge sharing and professional development.

- Led the implementation of a streamlined mixing process, reducing waste and increasing production efficiency by 10%.

Awards

- Recognized with the Formula Mixing Excellence Award for consistently delivering exceptional quality and efficiency in formula preparation.

- Awarded the Formula Mixer of the Year title for outstanding contributions and leadership in the formula mixing industry.

- Received the Safety Excellence Award for maintaining an impeccable safety record in the formula mixing facility.

- Honored with the Formula Mixing Innovation Award for developing a costeffective mixing method that increased yield while maintaining quality.

Certificates

- HACCP Certification

- IQA Certification

- ASQ Certification

- ISO 9001 Auditor Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Formula Mixer

- Highlight your technical skills in mixing and blending, as well as your knowledge of chemical handling and safety procedures.

- Showcase your ability to optimize processes and improve efficiency through the use of innovative techniques and technologies.

- Quantify your accomplishments with specific metrics, such as reductions in production time or customer complaints.

- Demonstrate your leadership skills and ability to work effectively in a team environment.

Essential Experience Highlights for a Strong Formula Mixer Resume

- Optimized production processes by implementing new mixing techniques, resulting in significant reduction in production time.

- Developed and implemented quality control systems to ensure consistent product quality, leading to a reduction in customer complaints.

- Led a team of mixers in the development and implementation of a new product line, contributing to increased sales.

- Provided technical support to customers, resolving complex mixing issues and providing guidance on best practices.

- Collaborated with engineers and other departments to optimize mixing processes and improve product quality.

- Maintained a safe and organized work environment, adhering to all safety protocols and regulations.

Frequently Asked Questions (FAQ’s) For Formula Mixer

What are the key qualities of a successful Formula Mixer?

Key qualities include a strong understanding of mixing principles, attention to detail, problem-solving abilities, and a commitment to safety.

What are the career prospects for Formula Mixers?

With experience, Formula Mixers can advance to roles such as Quality Control Supervisor, Production Manager, or Research and Development Engineer.

What are the educational requirements for becoming a Formula Mixer?

Most Formula Mixers hold a degree in Chemical Engineering or a related field.

What are the typical working conditions for Formula Mixers?

Formula Mixers typically work in industrial settings, operating mixing equipment and performing quality control tests. They may work in teams or independently, and may be exposed to chemicals and other hazards.

What are the safety protocols that Formula Mixers must follow?

Formula Mixers must adhere to strict safety protocols, including wearing protective gear, following proper mixing procedures, and maintaining a clean and organized work environment.

What are the challenges that Formula Mixers may face?

Formula Mixers may face challenges such as ensuring product quality, troubleshooting equipment issues, and meeting production deadlines.