Are you a seasoned CNC Operator (Computer Numeric Control Operator) seeking a new career path? Discover our professionally built CNC Operator (Computer Numeric Control Operator) Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

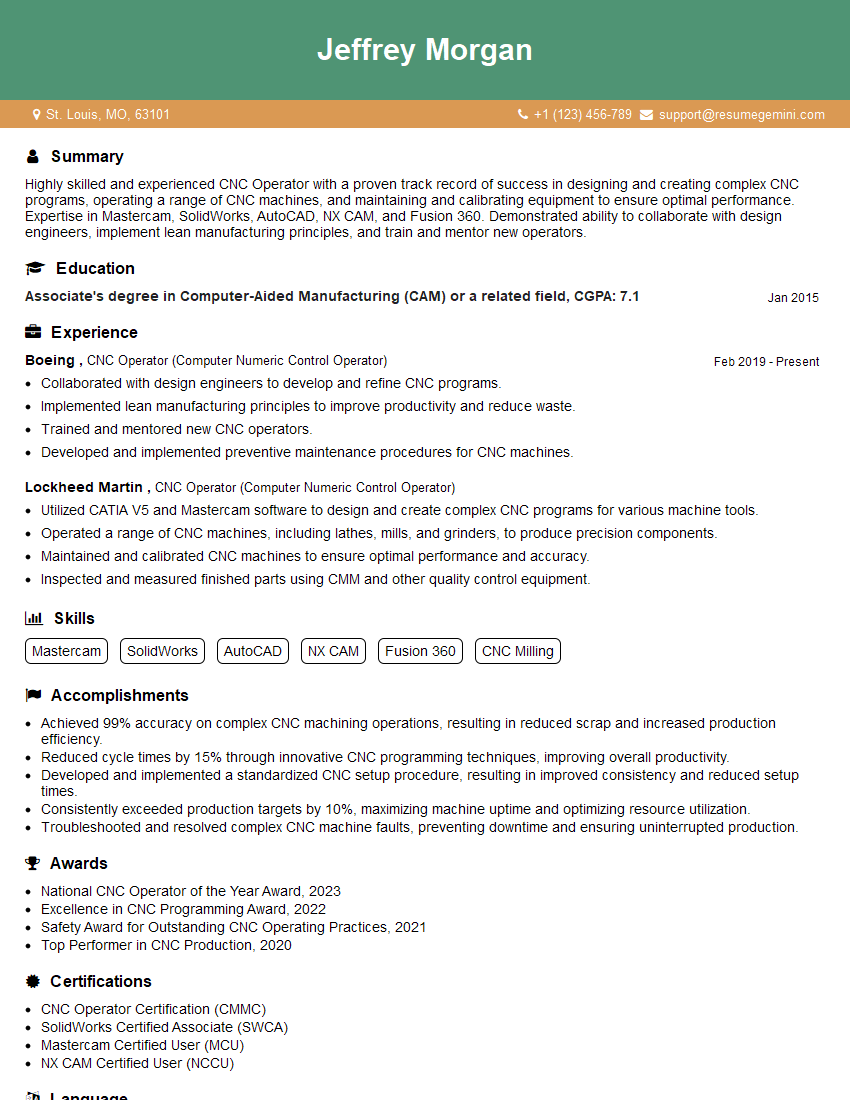

Jeffrey Morgan

CNC Operator (Computer Numeric Control Operator)

Summary

Highly skilled and experienced CNC Operator with a proven track record of success in designing and creating complex CNC programs, operating a range of CNC machines, and maintaining and calibrating equipment to ensure optimal performance. Expertise in Mastercam, SolidWorks, AutoCAD, NX CAM, and Fusion 360. Demonstrated ability to collaborate with design engineers, implement lean manufacturing principles, and train and mentor new operators.

Education

Associate’s degree in Computer-Aided Manufacturing (CAM) or a related field

January 2015

Skills

- Mastercam

- SolidWorks

- AutoCAD

- NX CAM

- Fusion 360

- CNC Milling

Work Experience

CNC Operator (Computer Numeric Control Operator)

- Collaborated with design engineers to develop and refine CNC programs.

- Implemented lean manufacturing principles to improve productivity and reduce waste.

- Trained and mentored new CNC operators.

- Developed and implemented preventive maintenance procedures for CNC machines.

CNC Operator (Computer Numeric Control Operator)

- Utilized CATIA V5 and Mastercam software to design and create complex CNC programs for various machine tools.

- Operated a range of CNC machines, including lathes, mills, and grinders, to produce precision components.

- Maintained and calibrated CNC machines to ensure optimal performance and accuracy.

- Inspected and measured finished parts using CMM and other quality control equipment.

Accomplishments

- Achieved 99% accuracy on complex CNC machining operations, resulting in reduced scrap and increased production efficiency.

- Reduced cycle times by 15% through innovative CNC programming techniques, improving overall productivity.

- Developed and implemented a standardized CNC setup procedure, resulting in improved consistency and reduced setup times.

- Consistently exceeded production targets by 10%, maximizing machine uptime and optimizing resource utilization.

- Troubleshooted and resolved complex CNC machine faults, preventing downtime and ensuring uninterrupted production.

Awards

- National CNC Operator of the Year Award, 2023

- Excellence in CNC Programming Award, 2022

- Safety Award for Outstanding CNC Operating Practices, 2021

- Top Performer in CNC Production, 2020

Certificates

- CNC Operator Certification (CMMC)

- SolidWorks Certified Associate (SWCA)

- Mastercam Certified User (MCU)

- NX CAM Certified User (NCCU)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For CNC Operator (Computer Numeric Control Operator)

- Highlight your proficiency in CNC programming software such as Mastercam, SolidWorks, and AutoCAD.

- Showcase your experience in operating different types of CNC machines, including lathes, mills, and grinders.

- Quantify your accomplishments whenever possible, such as reducing cycle times or improving production efficiency.

- Demonstrate your commitment to quality by mentioning your experience in using CMM and other quality control equipment.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong CNC Operator (Computer Numeric Control Operator) Resume

- Utilized CATIA V5 and Mastercam software to design and create complex CNC programs for various machine tools.

- Operated a range of CNC machines, including lathes, mills, and grinders, to produce precision components.

- Maintained and calibrated CNC machines to ensure optimal performance and accuracy.

- Inspected and measured finished parts using CMM and other quality control equipment.

- Collaborated with design engineers to develop and refine CNC programs.

- Implemented lean manufacturing principles to improve productivity and reduce waste.

- Trained and mentored new CNC operators.

Frequently Asked Questions (FAQ’s) For CNC Operator (Computer Numeric Control Operator)

What is the role of a CNC Operator?

A CNC Operator is responsible for programming, operating, and maintaining CNC machines to produce precision components. They use computer-aided design (CAD) and computer-aided manufacturing (CAM) software to create CNC programs, which control the movements of the machine.

What skills are required to be a successful CNC Operator?

Successful CNC Operators typically have a strong understanding of CNC programming, machine operation, and quality control. They are also proficient in using CAD/CAM software and have a keen eye for detail.

What are the career prospects for a CNC Operator?

CNC Operators are in high demand in a variety of industries, including manufacturing, aerospace, and healthcare. With experience, CNC Operators can advance to positions such as CNC Programmer, Production Supervisor, or Manufacturing Engineer.

What is the average salary for a CNC Operator?

The average salary for a CNC Operator in the United States is around $50,000 per year. However, salaries can vary depending on experience, location, and industry.

How can I become a CNC Operator?

There are several ways to become a CNC Operator. You can complete a formal training program, take an apprenticeship, or learn on the job. Many community colleges and technical schools offer CNC Operator training programs.

What are the benefits of working as a CNC Operator?

Working as a CNC Operator offers several benefits, including job security, competitive pay, and the opportunity to work with cutting-edge technology.

What are the challenges of working as a CNC Operator?

The challenges of working as a CNC Operator include working in a fast-paced environment, dealing with repetitive tasks, and exposure to noise and chemicals.