Are you a seasoned Metal CNC Operator seeking a new career path? Discover our professionally built Metal CNC Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

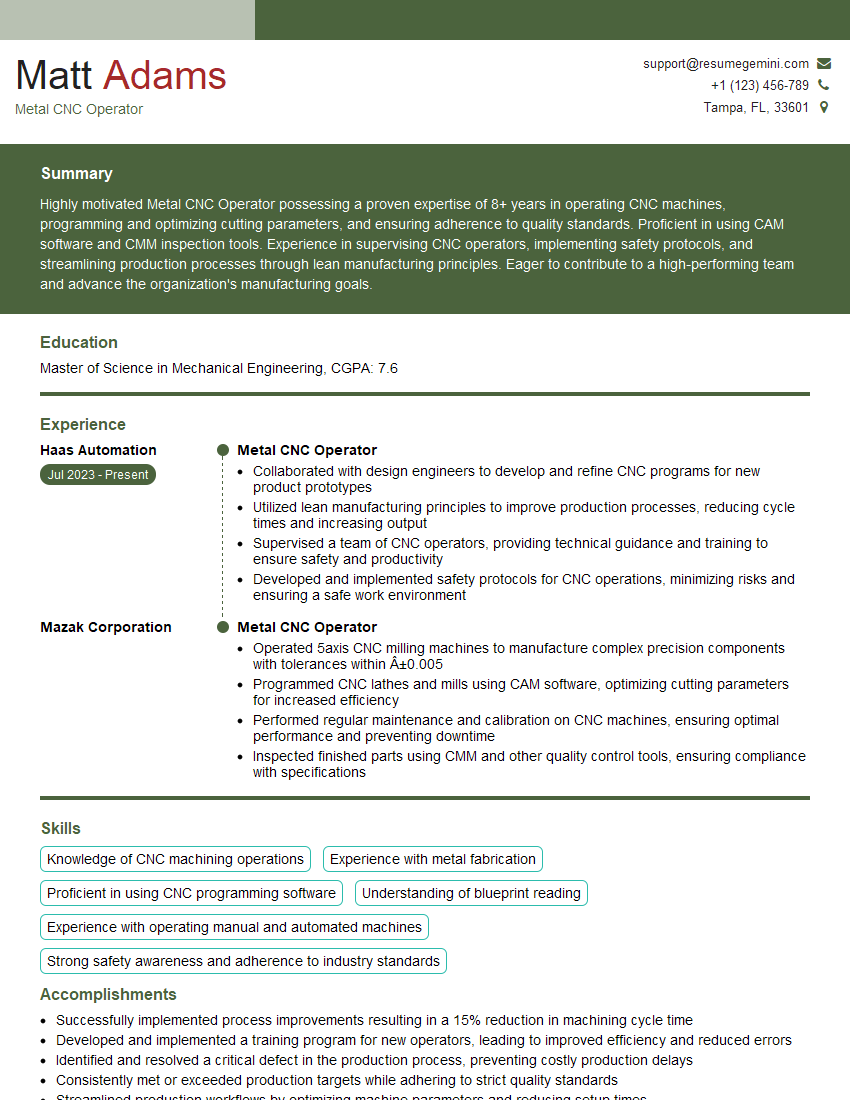

Matt Adams

Metal CNC Operator

Summary

Highly motivated Metal CNC Operator possessing a proven expertise of 8+ years in operating CNC machines, programming and optimizing cutting parameters, and ensuring adherence to quality standards. Proficient in using CAM software and CMM inspection tools. Experience in supervising CNC operators, implementing safety protocols, and streamlining production processes through lean manufacturing principles. Eager to contribute to a high-performing team and advance the organization’s manufacturing goals.

Education

Master of Science in Mechanical Engineering

June 2019

Skills

- Knowledge of CNC machining operations

- Experience with metal fabrication

- Proficient in using CNC programming software

- Understanding of blueprint reading

- Experience with operating manual and automated machines

- Strong safety awareness and adherence to industry standards

Work Experience

Metal CNC Operator

- Collaborated with design engineers to develop and refine CNC programs for new product prototypes

- Utilized lean manufacturing principles to improve production processes, reducing cycle times and increasing output

- Supervised a team of CNC operators, providing technical guidance and training to ensure safety and productivity

- Developed and implemented safety protocols for CNC operations, minimizing risks and ensuring a safe work environment

Metal CNC Operator

- Operated 5axis CNC milling machines to manufacture complex precision components with tolerances within ±0.005

- Programmed CNC lathes and mills using CAM software, optimizing cutting parameters for increased efficiency

- Performed regular maintenance and calibration on CNC machines, ensuring optimal performance and preventing downtime

- Inspected finished parts using CMM and other quality control tools, ensuring compliance with specifications

Accomplishments

- Successfully implemented process improvements resulting in a 15% reduction in machining cycle time

- Developed and implemented a training program for new operators, leading to improved efficiency and reduced errors

- Identified and resolved a critical defect in the production process, preventing costly production delays

- Consistently met or exceeded production targets while adhering to strict quality standards

- Streamlined production workflows by optimizing machine parameters and reducing setup times

Awards

- Recipient of the National Institute for Metalworking Skills (NIMS) CNC Programming Advanced Certification

- Recognized as the top Metal CNC Operator in the region based on annual performance evaluations

- Honored with the Presidents Award for outstanding contributions to the manufacturing team

- Received the Safety Excellence Award for maintaining an exemplary safety record

Certificates

- Certified CNC Operator through the National Institute for Metalworking Skills (NIMS)

- Certified Machinist through the Precision Machined Products Association (PMPA)

- Certified Maintenance and Reliability Technician (CMRT) through the Society for Maintenance & Reliability Professionals (SMRP)

- OSHA 30-Hour Safety Training Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal CNC Operator

- Quantify your accomplishments with specific metrics to showcase your impact on the organization.

- Highlight your expertise in programming software, inspection techniques, and safety protocols to demonstrate your technical proficiency.

- Showcase your problem-solving abilities and continuous improvement mindset through examples of how you optimized processes and increased efficiency.

- Emphasize your teamwork and leadership experience, as it demonstrates your ability to contribute effectively in a collaborative environment.

Essential Experience Highlights for a Strong Metal CNC Operator Resume

- Proficiently operated 5-axis CNC milling machines to manufacture intricate precision components with tolerances within ±0.005 inches.

- Programmed and optimized cutting parameters on CNC lathes and mills using CAM software to enhance efficiency and reduce cycle times.

- Conducted regular maintenance, calibration, and troubleshooting on CNC machines to ensure optimal performance and prevent downtime.

- Inspected finished parts using CMM and other quality control tools to verify compliance with specifications and maintain high-quality standards.

- Collaborated with design engineers and utilized lean manufacturing principles to refine CNC programs, prototype new products, and improve overall production processes.

- Supervised and mentored a team of CNC operators by providing technical guidance, training, and ensuring a safe and productive work environment.

Frequently Asked Questions (FAQ’s) For Metal CNC Operator

What are the key skills required to be a successful Metal CNC Operator?

Key skills for a Metal CNC Operator include proficiency in CNC machining operations, metal fabrication techniques, CNC programming software, blueprint reading, operating manual and automated machines, and strong safety awareness and adherence to industry standards.

What are the typical career paths for Metal CNC Operators?

Metal CNC Operators can advance to roles such as CNC Programmer, Manufacturing Supervisor, Quality Control Inspector, Process Engineer, or even start their own CNC machining business.

What are the earning prospects for Metal CNC Operators?

The earning potential for Metal CNC Operators varies depending on experience, skills, location, and industry. According to Indeed, the average salary for a CNC Operator in the United States is around $25 per hour or $52,000 per year.

What are the job market trends for Metal CNC Operators?

The job market for Metal CNC Operators is expected to remain stable or grow slightly in the coming years, as businesses continue to rely on CNC machining for precision manufacturing.

What are the common challenges faced by Metal CNC Operators?

Common challenges faced by Metal CNC Operators include working with complex designs, ensuring accuracy and precision, maintaining machine efficiency, and staying updated with the latest technologies and industry standards.

What are the essential qualities of a successful Metal CNC Operator?

Essential qualities of a successful Metal CNC Operator include a strong attention to detail, problem-solving abilities, mechanical aptitude, teamwork skills, and a commitment to safety.

What are the steps to becoming a certified Metal CNC Operator?

To become a certified Metal CNC Operator, you can consider obtaining certifications offered by organizations such as the National Institute for Metalworking Skills (NIMS) or the Society of Manufacturing Engineers (SME).