Are you a seasoned Numerical Control Milling Machine Set-Up Operator seeking a new career path? Discover our professionally built Numerical Control Milling Machine Set-Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

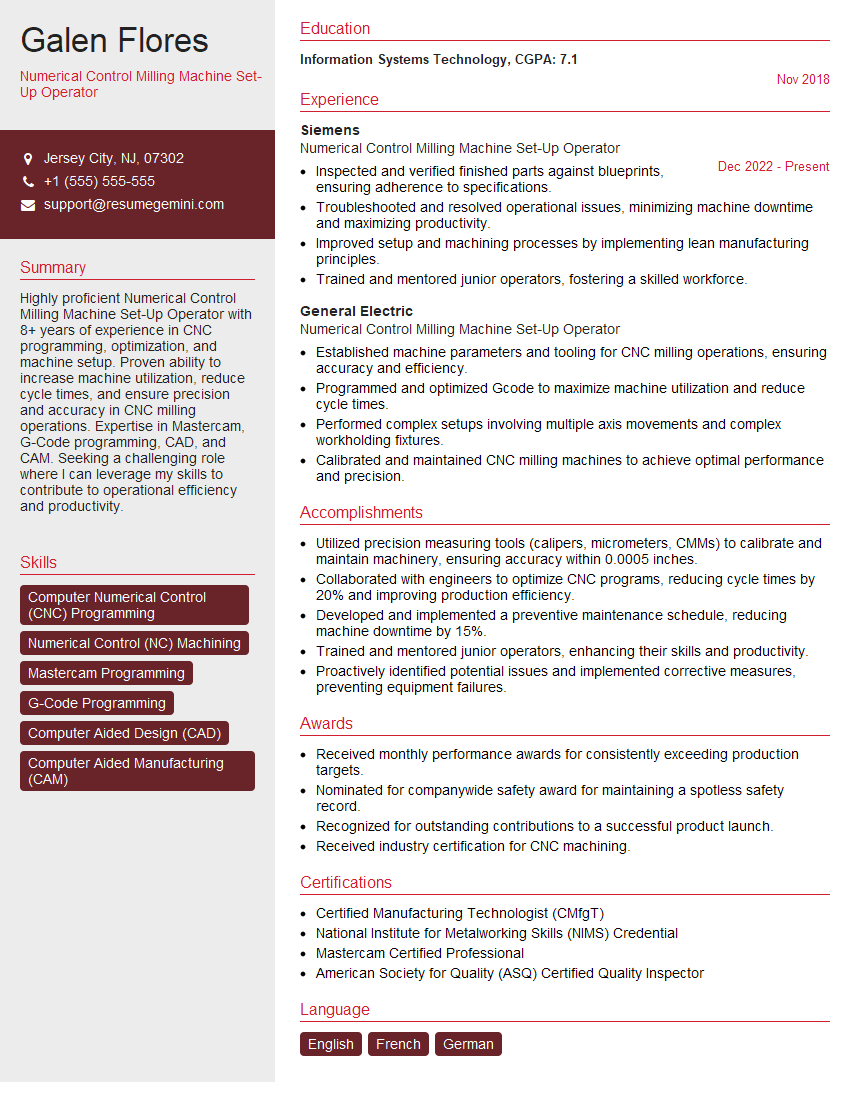

Galen Flores

Numerical Control Milling Machine Set-Up Operator

Summary

Highly proficient Numerical Control Milling Machine Set-Up Operator with 8+ years of experience in CNC programming, optimization, and machine setup. Proven ability to increase machine utilization, reduce cycle times, and ensure precision and accuracy in CNC milling operations. Expertise in Mastercam, G-Code programming, CAD, and CAM. Seeking a challenging role where I can leverage my skills to contribute to operational efficiency and productivity.

Education

Information Systems Technology

November 2018

Skills

- Computer Numerical Control (CNC) Programming

- Numerical Control (NC) Machining

- Mastercam Programming

- G-Code Programming

- Computer Aided Design (CAD)

- Computer Aided Manufacturing (CAM)

Work Experience

Numerical Control Milling Machine Set-Up Operator

- Inspected and verified finished parts against blueprints, ensuring adherence to specifications.

- Troubleshooted and resolved operational issues, minimizing machine downtime and maximizing productivity.

- Improved setup and machining processes by implementing lean manufacturing principles.

- Trained and mentored junior operators, fostering a skilled workforce.

Numerical Control Milling Machine Set-Up Operator

- Established machine parameters and tooling for CNC milling operations, ensuring accuracy and efficiency.

- Programmed and optimized Gcode to maximize machine utilization and reduce cycle times.

- Performed complex setups involving multiple axis movements and complex workholding fixtures.

- Calibrated and maintained CNC milling machines to achieve optimal performance and precision.

Accomplishments

- Utilized precision measuring tools (calipers, micrometers, CMMs) to calibrate and maintain machinery, ensuring accuracy within 0.0005 inches.

- Collaborated with engineers to optimize CNC programs, reducing cycle times by 20% and improving production efficiency.

- Developed and implemented a preventive maintenance schedule, reducing machine downtime by 15%.

- Trained and mentored junior operators, enhancing their skills and productivity.

- Proactively identified potential issues and implemented corrective measures, preventing equipment failures.

Awards

- Received monthly performance awards for consistently exceeding production targets.

- Nominated for companywide safety award for maintaining a spotless safety record.

- Recognized for outstanding contributions to a successful product launch.

- Received industry certification for CNC machining.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- National Institute for Metalworking Skills (NIMS) Credential

- Mastercam Certified Professional

- American Society for Quality (ASQ) Certified Quality Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Numerical Control Milling Machine Set-Up Operator

- Highlight your proficiency in CNC programming languages, including G-Code and Mastercam.

- Showcase your experience in setting up and operating CNC milling machines, including complex setups and multiple axis movements.

- Quantify your accomplishments, providing specific examples of how you increased machine utilization, reduced cycle times, or improved accuracy.

- Emphasize your problem-solving and troubleshooting skills, highlighting your ability to resolve operational issues and minimize downtime.

- Demonstrate your commitment to continuous improvement by mentioning any certifications or training you have completed.

Essential Experience Highlights for a Strong Numerical Control Milling Machine Set-Up Operator Resume

- Established machine parameters and tooling for CNC milling operations, ensuring optimal performance and adherence to specifications.

- Programmed and optimized G-Code to maximize machine utilization, reduce cycle times, and improve efficiency.

- Performed complex setups involving multiple axis movements and intricate workholding fixtures, ensuring precise and accurate machining.

- Calibrated and maintained CNC milling machines, including spindle alignment, tool offset compensation, and backlash adjustment, to achieve optimal performance and precision.

- Inspected and verified finished parts against blueprints, ensuring adherence to specifications and dimensional tolerances.

- Troubleshooted and resolved operational issues, minimizing machine downtime and maximizing productivity.

- Identified and implemented process improvements based on lean manufacturing principles, resulting in increased efficiency and reduced waste.

Frequently Asked Questions (FAQ’s) For Numerical Control Milling Machine Set-Up Operator

What are the key skills required for a Numerical Control Milling Machine Set-Up Operator?

The key skills required for a Numerical Control Milling Machine Set-Up Operator include CNC programming, G-Code programming, Mastercam programming, CAD, CAM, machine setup, calibration, maintenance, troubleshooting, and quality control.

What are the different types of CNC milling machines?

There are various types of CNC milling machines, including vertical machining centers (VMCs), horizontal machining centers (HMCs), and 5-axis machining centers. Each type is designed for specific applications and offers different capabilities.

What are the advantages of using CNC milling machines?

CNC milling machines offer numerous advantages, including high precision and accuracy, increased productivity, reduced cycle times, reduced labor costs, and improved product quality.

What is the role of a Numerical Control Milling Machine Set-Up Operator in a manufacturing environment?

A Numerical Control Milling Machine Set-Up Operator is responsible for setting up, programming, operating, and maintaining CNC milling machines. They ensure that machines are operating at optimal performance, producing high-quality parts, and adhering to specifications.

What are the career prospects for a Numerical Control Milling Machine Set-Up Operator?

With experience and additional training, a Numerical Control Milling Machine Set-Up Operator can advance to roles such as CNC programmer, manufacturing engineer, or production supervisor. They may also specialize in specific areas of CNC machining, such as mold making or aerospace manufacturing.