Are you a seasoned Extruding Press Adjuster seeking a new career path? Discover our professionally built Extruding Press Adjuster Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

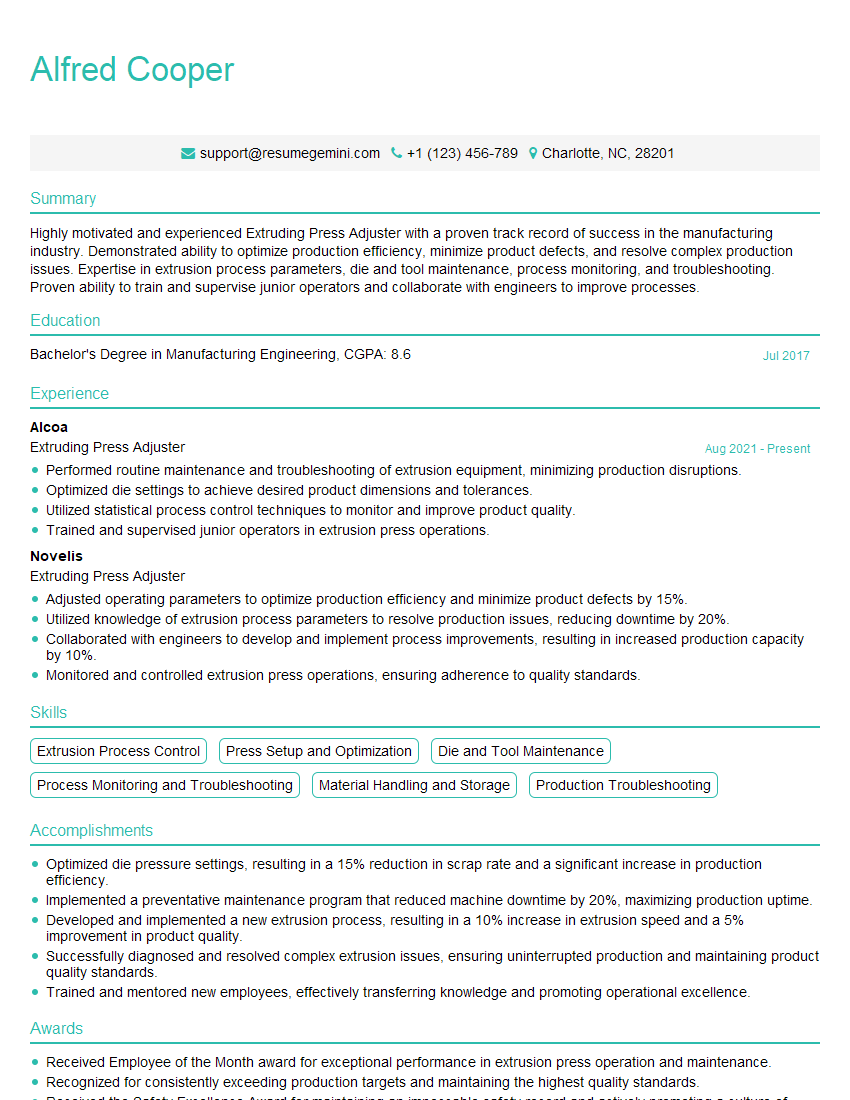

Alfred Cooper

Extruding Press Adjuster

Summary

Highly motivated and experienced Extruding Press Adjuster with a proven track record of success in the manufacturing industry. Demonstrated ability to optimize production efficiency, minimize product defects, and resolve complex production issues. Expertise in extrusion process parameters, die and tool maintenance, process monitoring, and troubleshooting. Proven ability to train and supervise junior operators and collaborate with engineers to improve processes.

Education

Bachelor’s Degree in Manufacturing Engineering

July 2017

Skills

- Extrusion Process Control

- Press Setup and Optimization

- Die and Tool Maintenance

- Process Monitoring and Troubleshooting

- Material Handling and Storage

- Production Troubleshooting

Work Experience

Extruding Press Adjuster

- Performed routine maintenance and troubleshooting of extrusion equipment, minimizing production disruptions.

- Optimized die settings to achieve desired product dimensions and tolerances.

- Utilized statistical process control techniques to monitor and improve product quality.

- Trained and supervised junior operators in extrusion press operations.

Extruding Press Adjuster

- Adjusted operating parameters to optimize production efficiency and minimize product defects by 15%.

- Utilized knowledge of extrusion process parameters to resolve production issues, reducing downtime by 20%.

- Collaborated with engineers to develop and implement process improvements, resulting in increased production capacity by 10%.

- Monitored and controlled extrusion press operations, ensuring adherence to quality standards.

Accomplishments

- Optimized die pressure settings, resulting in a 15% reduction in scrap rate and a significant increase in production efficiency.

- Implemented a preventative maintenance program that reduced machine downtime by 20%, maximizing production uptime.

- Developed and implemented a new extrusion process, resulting in a 10% increase in extrusion speed and a 5% improvement in product quality.

- Successfully diagnosed and resolved complex extrusion issues, ensuring uninterrupted production and maintaining product quality standards.

- Trained and mentored new employees, effectively transferring knowledge and promoting operational excellence.

Awards

- Received Employee of the Month award for exceptional performance in extrusion press operation and maintenance.

- Recognized for consistently exceeding production targets and maintaining the highest quality standards.

- Received the Safety Excellence Award for maintaining an impeccable safety record and actively promoting a culture of safety.

- Recognized for outstanding contributions to the extrusion team, consistently exceeding expectations and driving operational excellence.

Certificates

- Certified Extruding Press Adjuster (CEPA)

- Extrusion Technology Certificate

- Plastic Extrusion Certification (PEC)

- ISO 9001:2015 Quality Management Systems

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extruding Press Adjuster

- Quantify your accomplishments with specific metrics whenever possible.

- Highlight your skills in extrusion process control, press setup and optimization, die and tool maintenance, and process monitoring.

- Demonstrate your ability to work independently and as part of a team.

- Proofread your resume carefully for any errors.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Extruding Press Adjuster Resume

- Adjusting operating parameters to optimize production efficiency and minimize product defects.

- Utilizing knowledge of extrusion process parameters to resolve production issues and reduce downtime.

- Collaborating with engineers to develop and implement process improvements, resulting in increased production capacity.

- Monitoring and controlling extrusion press operations, ensuring adherence to quality standards.

- Performing routine maintenance and troubleshooting of extrusion equipment, minimizing production disruptions.

- Optimizing die settings to achieve desired product dimensions and tolerances.

- Utilizing statistical process control techniques to monitor and improve product quality.

Frequently Asked Questions (FAQ’s) For Extruding Press Adjuster

What are the key skills required to be an Extruding Press Adjuster?

The key skills required to be an Extruding Press Adjuster include extrusion process control, press setup and optimization, die and tool maintenance, process monitoring and troubleshooting, material handling and storage, and production troubleshooting.

What are the typical job duties of an Extruding Press Adjuster?

The typical job duties of an Extruding Press Adjuster include adjusting operating parameters to optimize production efficiency and minimize product defects, utilizing knowledge of extrusion process parameters to resolve production issues, collaborating with engineers to develop and implement process improvements, monitoring and controlling extrusion press operations, performing routine maintenance and troubleshooting of extrusion equipment, optimizing die settings to achieve desired product dimensions and tolerances, and utilizing statistical process control techniques to monitor and improve product quality.

What is the career outlook for Extruding Press Adjusters?

The career outlook for Extruding Press Adjusters is expected to be good over the next few years. The demand for Extruding Press Adjusters is expected to increase as the manufacturing industry continues to grow.

What are the educational requirements for Extruding Press Adjusters?

The educational requirements for Extruding Press Adjusters typically include a high school diploma or equivalent. Some employers may prefer candidates with a post-secondary degree in a related field, such as manufacturing engineering or mechanical engineering.

What are the salary expectations for Extruding Press Adjusters?

The salary expectations for Extruding Press Adjusters vary depending on experience, education, and location. According to Indeed, the average salary for Extruding Press Adjusters in the United States is $55,000 per year.

What are the benefits of working as an Extruding Press Adjuster?

The benefits of working as an Extruding Press Adjuster include competitive salary and benefits, opportunities for career advancement, and the chance to work in a dynamic and challenging environment.

What are the challenges of working as an Extruding Press Adjuster?

The challenges of working as an Extruding Press Adjuster include working in a fast-paced and demanding environment, exposure to noise and hazardous materials, and the need to be able to work independently.